Building an H2H mount

- Thread starter Greg Mueller

- Start date

- Latest activity Latest activity:

- Replies 51

- Views 9K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Please reply by conversation.

The problem in trying to build and H2H mount is finding an industrial (one for power transmission rather than position) worm gear of large diameter. I've wrestled with the same problem while building a telescope mount.

I finally come to the conclusion that the technique that Paraclipse used and another company currently uses is heavy chain mounted on a arc. It just so happens I have some big chain left over from a previous project and I think a small cog too.

It looks like this could be adaptable to many mounts that are currently position with an actuator arm. If you really wanted to get classy you could use a very large "V belt" pulley cut in half, but the simple method pictured below would work just fine

I finally come to the conclusion that the technique that Paraclipse used and another company currently uses is heavy chain mounted on a arc. It just so happens I have some big chain left over from a previous project and I think a small cog too.

It looks like this could be adaptable to many mounts that are currently position with an actuator arm. If you really wanted to get classy you could use a very large "V belt" pulley cut in half, but the simple method pictured below would work just fine

Attachments

Interesting, but I'd be worried about the play or "slop" as I would call it as an engineering lay person. Even My Birdview HH mover has a little of that. I think chain and sprocket units have some of that built in.

I'd be worried about wear on both, since chains are usually designed to go around sprockets, rather than contact only one or two teeth.

Just a thought on an automotive item. Although steering mechanisms today are often rack and pinion, they used to be more often steering boxes. Those had a worm gear mechanism. I don't know if that would be adaptable.

I'd be worried about wear on both, since chains are usually designed to go around sprockets, rather than contact only one or two teeth.

Just a thought on an automotive item. Although steering mechanisms today are often rack and pinion, they used to be more often steering boxes. Those had a worm gear mechanism. I don't know if that would be adaptable.

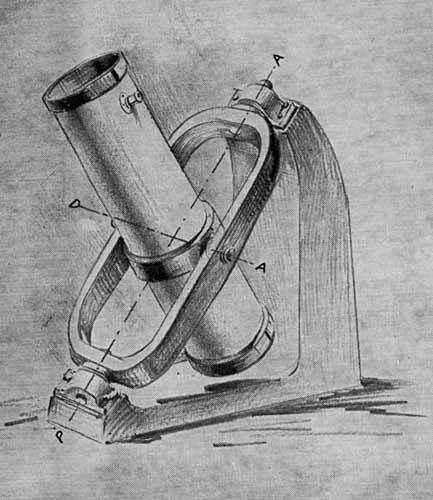

That's built with the same general design as the big mount on Stogie's Paraclipse dish.

Did you actually build it? Or is that something you found? Looks real good.

Show us some more pictures from different angles.

I'd be especially interested in where you shoved the magnet wheel.

Did you actually build it? Or is that something you found? Looks real good.

Show us some more pictures from different angles.

I'd be especially interested in where you shoved the magnet wheel.

I just found that picture of a mount that is being offered by a commercial supplier.

I don't have any other pictures, but if I get into construction I will take some.

I don't have any other pictures, but if I get into construction I will take some.

I'm figuring gear ratios and speed reducers and was hoping someone who has an H2H mount could tell me how long it takes (seconds or minutes) to go 45° or 90° or 180°.

Thanks

Thanks

Birdview HH goes from due south to all the way east (or west) in, i'm estimating, less than half a minute. They advertised it as 140 degrees of total "arc" ( or travel or whatever you call it) , so that is travel of 70 degrees in that half minute.

It doesn't make you wait.

It doesn't make you wait.

Birdview motors

That's for the 37:1 model.

They also made a 70:1 and a 110:1 version.

Those ratios don't include the final worm to main-gear ratio.

One concern, is that you may get the big dish movin', but then not be able to stop it on a dime once you get where you want to go.

So, I'd be happy to find the 70:1 or even the 110:1 gearbox, and put up with the wait time.

And the finer your feedback sensor, the more worry the speed will be.

I don't think V-boxes nor even the better G-boxes, deal well with overshoot.

But, we really don't know.

Edit: also, the actual motor speeds are written on the nameplates.

If you want that info, I can probably dig it out of my picture archives before you can search out all the Birdview threads and pictures.

That's for the 37:1 model.

They also made a 70:1 and a 110:1 version.

Those ratios don't include the final worm to main-gear ratio.

One concern, is that you may get the big dish movin', but then not be able to stop it on a dime once you get where you want to go.

So, I'd be happy to find the 70:1 or even the 110:1 gearbox, and put up with the wait time.

And the finer your feedback sensor, the more worry the speed will be.

I don't think V-boxes nor even the better G-boxes, deal well with overshoot.

But, we really don't know.

Edit: also, the actual motor speeds are written on the nameplates.

If you want that info, I can probably dig it out of my picture archives before you can search out all the Birdview threads and pictures.

Last edited:

Yep

Overcoming inertia (starting and stopping) has me concerned. I'm kind of surprised Birdview got away with such a smallish worm wheel, but it does explain why the wheel is steel and not bronze.

Overcoming inertia (starting and stopping) has me concerned. I'm kind of surprised Birdview got away with such a smallish worm wheel, but it does explain why the wheel is steel and not bronze.

more on Birdview motors

This info is taken from the nameplates on pictures of motors, and one web page with a few specs.

37:1 motor, most common

Von Weise, series B-85 and C-85

models V03554AF33 and V03554AE33 , respectively

36v dc, intermittent operation

2.5 amps

rpm: 1650

shaft: 45 (?)

1/10th horsepower

64 inch/pounds

70:1 motor,

Von Weise

rpm: 1650

shaft: 24 (?)

122 inch/pounds

110:1 motor

Patterson Gear Motor

model: BV-202

36 v dc, intermittent, 5 minutes

5 amps

shaft: 22 rpm (maybe this motor runs faster?)

150 inch/ pounds

This info is taken from the nameplates on pictures of motors, and one web page with a few specs.

37:1 motor, most common

Von Weise, series B-85 and C-85

models V03554AF33 and V03554AE33 , respectively

36v dc, intermittent operation

2.5 amps

rpm: 1650

shaft: 45 (?)

1/10th horsepower

64 inch/pounds

70:1 motor,

Von Weise

rpm: 1650

shaft: 24 (?)

122 inch/pounds

110:1 motor

Patterson Gear Motor

model: BV-202

36 v dc, intermittent, 5 minutes

5 amps

shaft: 22 rpm (maybe this motor runs faster?)

150 inch/ pounds

Sounds like the last one would be my choice. Is there any way to tell which order they were issued in?

If I had a 110:1, I'd trade it to you for the 70:1, I think.

But, you want one for your own H-H mount, and I actually want one to put on a Birdview. -

As for availability, I'm researching if they offered the slower motors as an option, but not finding any proof.

Instead, I came across this quote from one of their brochures:

Motor: DC permanent magnet, 36 volt, 1/10 horsepower

Backlash: Eccentric bearing adjustable

Gearing: Sealed gear motor driving a worm and 12" helical sector gear supported by diecast A-frame assembly

Tracking range over 140°

If your H-H does as well, it'll be dandy!

But, you want one for your own H-H mount, and I actually want one to put on a Birdview. -

As for availability, I'm researching if they offered the slower motors as an option, but not finding any proof.

Instead, I came across this quote from one of their brochures:

Motor: DC permanent magnet, 36 volt, 1/10 horsepower

Backlash: Eccentric bearing adjustable

Gearing: Sealed gear motor driving a worm and 12" helical sector gear supported by diecast A-frame assembly

Tracking range over 140°

If your H-H does as well, it'll be dandy!

If I had a 110:1, I'd trade it to you for the 70:1, I think.

But, you want one for your own H-H mount, and I actually want one to put on a Birdview. -

If I could find a Birdview (or any H2H mount) I would take it in a heartbeat (and be happy)

I've got one of each, and my experience is, I'll take the Paraclipse system over the Birdview system. Any Day. The Paraclipse has so much more movement than the Birdview...from my location I can see all the way down to 43w with either dish, BUT, the Paraclipse still has more to give should I want to go farther, but by the time the Birdview gets to 43 its getting dangerously close to running out. I can run the Paraclipse danged near into the ground, and the top of my dish mast is 5 feet OFF the ground.

Now, the Birdview system is MUCH more robust, IMO, than the Paraclipse system, the Paraclipse has a chain and idler sprockets which will wear over time, the Birdview has a steel gear with a steel worm, you're not going to wear that out in any of our lifetimes.

I'd take you some pics of the Paraclipse system, but they way its made you cannot see the sprokets and such without completely disassembling the entire system. Which I ain't going to do...LOL....

As far as accuracy, the Paraclipse is much more accurate than the Birdview, but my Birdview has the 37:1 gearbox, so it really hauls ass. Really too fast. The Birdview is hard to get exactly on a satellite with the manual positioner I use, I don't know HOW a programmable mover would work with either, as I don't have one. But IIRC the Paraclipse has a 135:1 box I think....

Now, the Birdview system is MUCH more robust, IMO, than the Paraclipse system, the Paraclipse has a chain and idler sprockets which will wear over time, the Birdview has a steel gear with a steel worm, you're not going to wear that out in any of our lifetimes.

I'd take you some pics of the Paraclipse system, but they way its made you cannot see the sprokets and such without completely disassembling the entire system. Which I ain't going to do...LOL....

As far as accuracy, the Paraclipse is much more accurate than the Birdview, but my Birdview has the 37:1 gearbox, so it really hauls ass. Really too fast. The Birdview is hard to get exactly on a satellite with the manual positioner I use, I don't know HOW a programmable mover would work with either, as I don't have one. But IIRC the Paraclipse has a 135:1 box I think....

Last edited:

faster motor

We were just talking about these motors and gear ratios, so I calculated how fast the 110:1 motor must go to get that output shaft speed.

It seems like 2400 rpm would do it.

This is about the same output shaft speed as the 70:1 on the slower 1650 rpm motor.

And it takes 5 amps , not 2.5 amps.

We were just talking about these motors and gear ratios, so I calculated how fast the 110:1 motor must go to get that output shaft speed.

It seems like 2400 rpm would do it.

This is about the same output shaft speed as the 70:1 on the slower 1650 rpm motor.

And it takes 5 amps , not 2.5 amps.

Greg;

I wonder if the flex plate off say a chevy 350 motor cut in half would work for the half moon section of the drive? It's big enough and cheap and sturdy. Driving it with a dc gear reducer motor would give enough torque I think to push the dish.

I wonder if the flex plate off say a chevy 350 motor cut in half would work for the half moon section of the drive? It's big enough and cheap and sturdy. Driving it with a dc gear reducer motor would give enough torque I think to push the dish.

Greg;

I wonder if the flex plate off say a chevy 350 motor cut in half would work for the half moon section of the drive? It's big enough and cheap and sturdy. Driving it with a dc gear reducer motor would give enough torque I think to push the dish.

Use a flywheel off a manual-shift truck instead. its thicker. Only problem is finding something to DRIVE that flywheel...a starter motor I don't think will work...just a TAD too fast...LOL

- Status

- Please reply by conversation.

Similar threads

- Replies

- 9

- Views

- 1K

- Replies

- 2

- Views

- 2K

- Replies

- 5

- Views

- 421

- Replies

- 3

- Views

- 2K

- Replies

- 54

- Views

- 4K