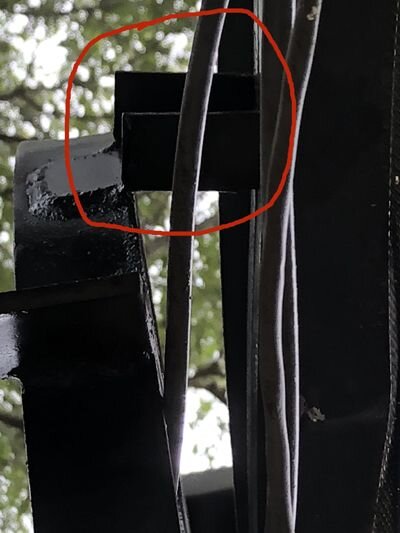

Hi All,

In my continuing saga to return my dish to a better parabolic shape after its "fall" from grace several years ago, I made a discovery today. I noticed that one of the rib supports, for lack of a better term, was bent inward, forcing that section of my dish inwards, pushing it out of shape in relation to the other dish "petals".

Of course I figured if I could detach the rib from this support, I could either hammer this support upright where it should be or drill another hole farther down the support and help get that "petal" in better alignment with the others.

Unfortunately 20 years of Cape Cod weather have rusted this bolt and despite using PB Blaster which loosened it just a bit, I'm wondering what my next step should be. Its a tight fit so sawing off the nut would be difficult at best. Any suggestions from all you experts out there ??

I've enclosed some pictures.

Thanks in advance.

John

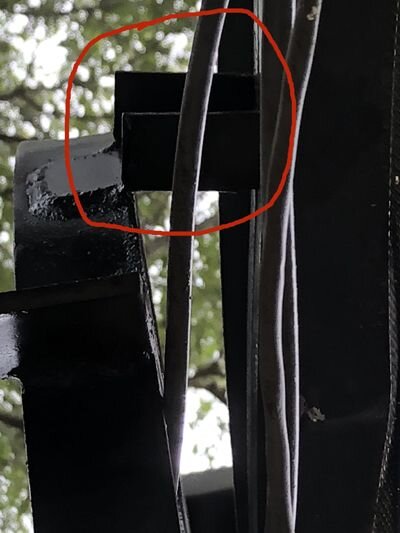

In my continuing saga to return my dish to a better parabolic shape after its "fall" from grace several years ago, I made a discovery today. I noticed that one of the rib supports, for lack of a better term, was bent inward, forcing that section of my dish inwards, pushing it out of shape in relation to the other dish "petals".

Of course I figured if I could detach the rib from this support, I could either hammer this support upright where it should be or drill another hole farther down the support and help get that "petal" in better alignment with the others.

Unfortunately 20 years of Cape Cod weather have rusted this bolt and despite using PB Blaster which loosened it just a bit, I'm wondering what my next step should be. Its a tight fit so sawing off the nut would be difficult at best. Any suggestions from all you experts out there ??

I've enclosed some pictures.

Thanks in advance.

John