Can we use polycarbonate plate instead of teflon ?

- Thread starter john_robot

- Start date

- Latest activity Latest activity:

- Replies 9

- Views 3K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Please reply by conversation.

Well, what are we building? A boat? Racecar? Frying pan?

Can you elaborate a bit? I might be able to help.

Can you elaborate a bit? I might be able to help.

actually, while I know it's often called teflon, is it really teflon that is commonly used?

All the dielectric plate that I've used for circular C-band looked very much like printed circuit board stuff (fiberglass-reinforced epoxy resin), just a lot thicker than a PCB. And recently I had to file the edges of a plate I got with my Titanium LNBF to fit it in an old Polarotor, and filing it produced the exact same smell as you get when drilling/cutting a PCB board.

Also, I think I have seen a Dish Network LNBF that used a transparent dielectric plate - so maybe it was polycarbonate.

All the dielectric plate that I've used for circular C-band looked very much like printed circuit board stuff (fiberglass-reinforced epoxy resin), just a lot thicker than a PCB. And recently I had to file the edges of a plate I got with my Titanium LNBF to fit it in an old Polarotor, and filing it produced the exact same smell as you get when drilling/cutting a PCB board.

Also, I think I have seen a Dish Network LNBF that used a transparent dielectric plate - so maybe it was polycarbonate.

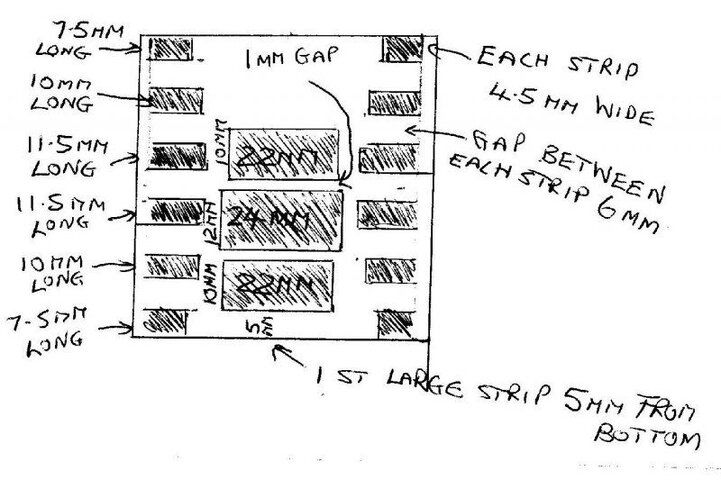

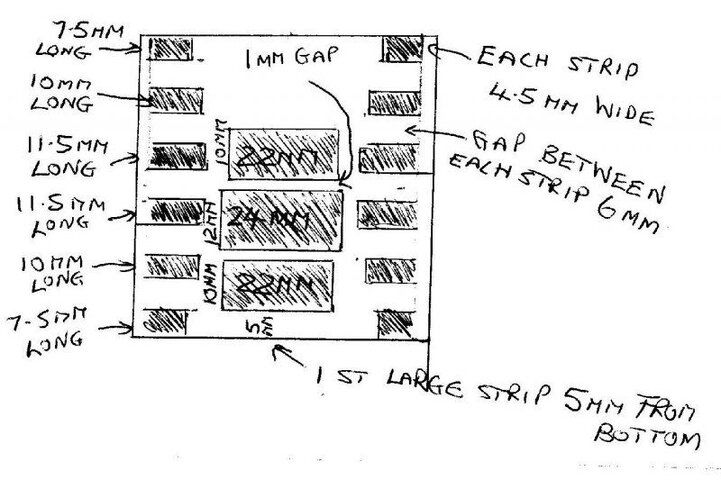

Hi, Do you have the measurement details of the metal plates that you have on the plastic plate ?

John, let me ask the guy that made the one I'm using, it may take a few days to get a reply from him but I'll let you know what he says.

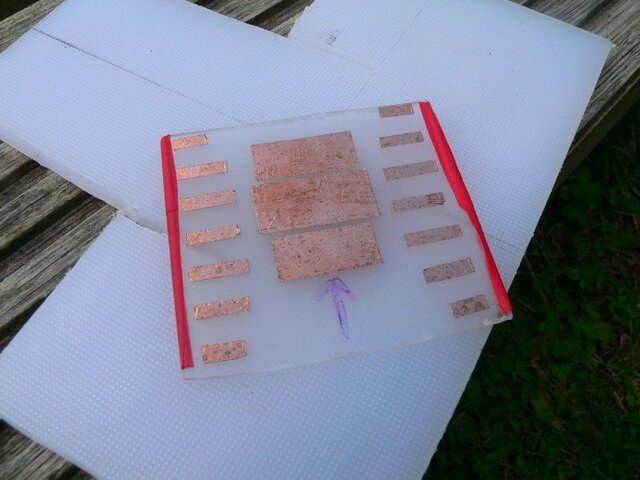

cool, i'm interested too. Is that a copper-clad printed circuit board that was etched with that specific pattern? Or is it adhesive copper on a polycarbonate board from a CD case?John, let me ask the guy that made the one I'm using, it may take a few days to get a reply from him but I'll let you know what he says.

I've heard back from him and have the diagram. He's currently experimenting with the design and adding some extra lengths of copper wire to each copper plate, hopefully he's going to send me a photo to show what's he done but he says he's improved some transponders by over half a dB so I'll update as and when I get something.

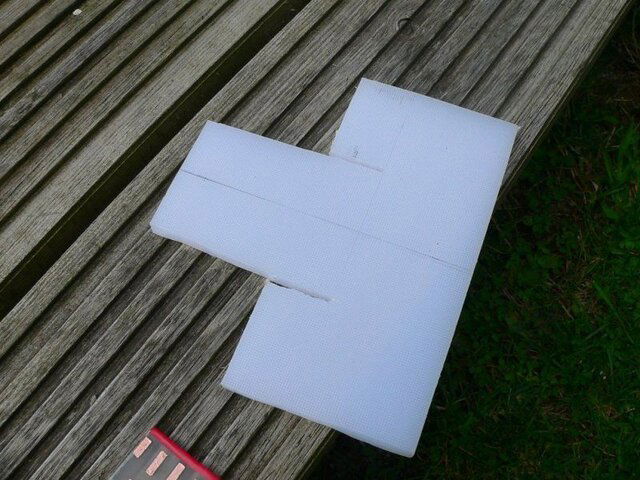

The plate itself is made from a CD case, no idea what type of plastic that is but he just dremmels out the size required to snug fit in the LNB and you'll see it's made slightly longer than required. I don't know where he sourced the copper from but it comes on a sheet and is self adhesive.

I've placed a couple of strips of PVC tape down each side of mine just to give it a cushion as it's slid into the LNB and the position within the throat is quite sensitive so trial and error to find the best location. Mine is with the upper most copper strips about 10MM from the front of the throat.

The plate itself is made from a CD case, no idea what type of plastic that is but he just dremmels out the size required to snug fit in the LNB and you'll see it's made slightly longer than required. I don't know where he sourced the copper from but it comes on a sheet and is self adhesive.

I've placed a couple of strips of PVC tape down each side of mine just to give it a cushion as it's slid into the LNB and the position within the throat is quite sensitive so trial and error to find the best location. Mine is with the upper most copper strips about 10MM from the front of the throat.

PLEASE LOG IN TO GET RID OF THESE ADS!

- Status

- Please reply by conversation.

Similar threads

- Replies

- 19

- Views

- 567

- Replies

- 16

- Views

- 2K

- Replies

- 1

- Views

- 812

- Replies

- 2

- Views

- 714

Users Who Are Viewing This Thread (Total: 0, Members: 0, Guests: 0)

Who Read This Thread (Total Members: 2)

Latest posts

-

-

TLCD TVs Got a Crazy Upgrade: RGB Mini & Micro LED

- Latest: TWiT Tech Podcast Network