And the manual tells you to look up the elevation / declination settings depending on your latitude. No problem so far...

It then tells you to set the elevation angle of the motor - no doubt from that table you just looked at. - No problem...

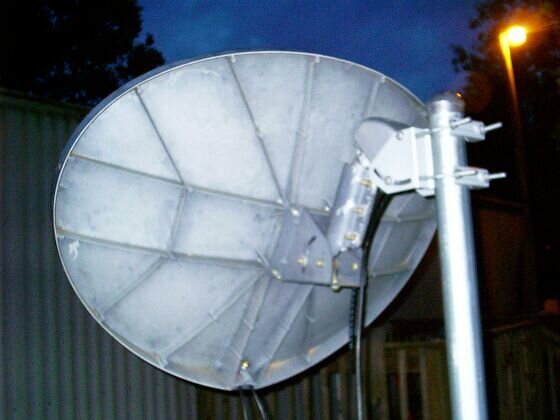

It then tells you to find you declination angle on the table and it's a small number - like 8°. It then says "Set the declination angle by the scale on the antenna dish. The reading on the dish scale should be 40° declination angle".

Why did They have me look up the declination angle if I'm just going to set it to 40°?

Maybe this will make more sense when I have this stuff in hand - lol.

It then tells you to set the elevation angle of the motor - no doubt from that table you just looked at. - No problem...

It then tells you to find you declination angle on the table and it's a small number - like 8°. It then says "Set the declination angle by the scale on the antenna dish. The reading on the dish scale should be 40° declination angle".

Why did They have me look up the declination angle if I'm just going to set it to 40°?

Maybe this will make more sense when I have this stuff in hand - lol.