Having been the winner of the recent WSI contest for a prize package including their WSI9036 dish and Powermax SG-9120 motor, I am proud to write a review of these new products from our sponsor WS International.

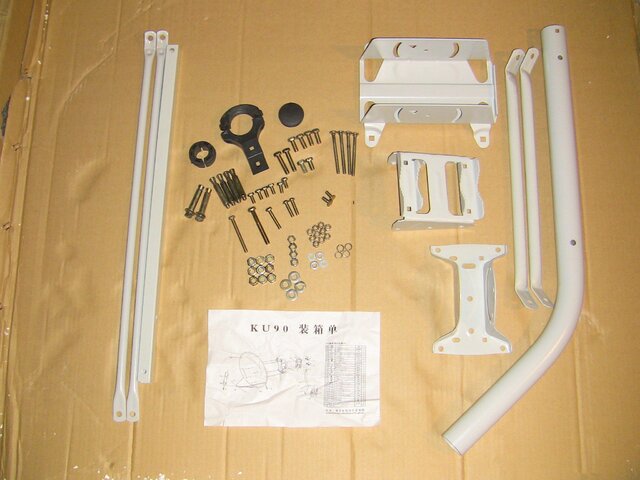

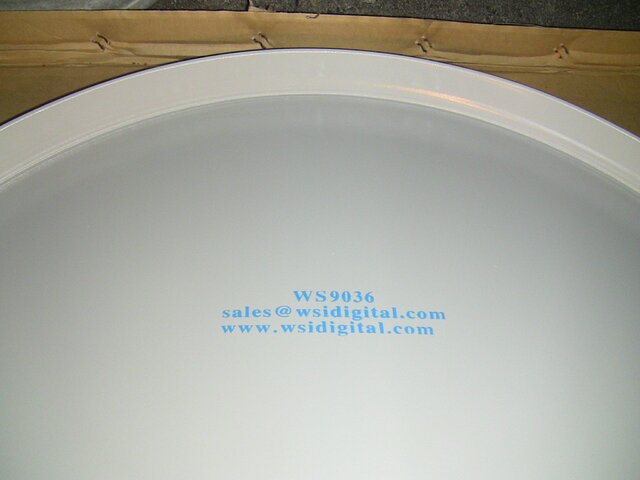

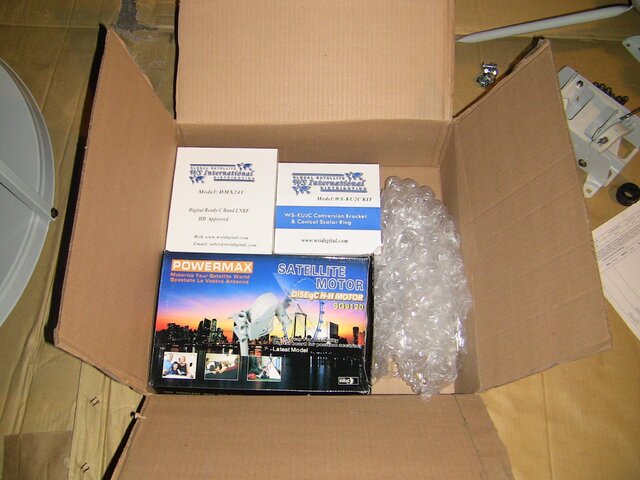

Getting these products was a pleasant surprise, as I don't recall ever having won a contest in my life. I was waist-deep in the assembly and installation of my new C-Band dish, and by the time it was off the patio and on its stand, I was receiving this wonderful package. When I called to confirm my address, I chatted with Robby about possibly attempting some C-Band on the WS9036. I know this is a long shot, but I figured I'd try anyway. Since the WS9036 is the largest 90CM dish out there, measuring 90CM wide by 99CM high, it might just get some C-Band. When I opened the boxes, I was in for another pleasant surprise, which I will go into later in the review.

Since the roof farm, as it will be called from now on, is very low on real estate, I decided to hunt down another wooden pallet and mount the new dish and motor on a poor man's NPRM. I ran two dual coax cables (total of four individual cables for future expansion) out to the C-Band dish early this week, so there was already coax in place in that location. For the purposes of this review, I will skip the pallet and mount construction procedure, since it has been covered before in other reviews.

Getting these products was a pleasant surprise, as I don't recall ever having won a contest in my life. I was waist-deep in the assembly and installation of my new C-Band dish, and by the time it was off the patio and on its stand, I was receiving this wonderful package. When I called to confirm my address, I chatted with Robby about possibly attempting some C-Band on the WS9036. I know this is a long shot, but I figured I'd try anyway. Since the WS9036 is the largest 90CM dish out there, measuring 90CM wide by 99CM high, it might just get some C-Band. When I opened the boxes, I was in for another pleasant surprise, which I will go into later in the review.

Since the roof farm, as it will be called from now on, is very low on real estate, I decided to hunt down another wooden pallet and mount the new dish and motor on a poor man's NPRM. I ran two dual coax cables (total of four individual cables for future expansion) out to the C-Band dish early this week, so there was already coax in place in that location. For the purposes of this review, I will skip the pallet and mount construction procedure, since it has been covered before in other reviews.

Last edited: