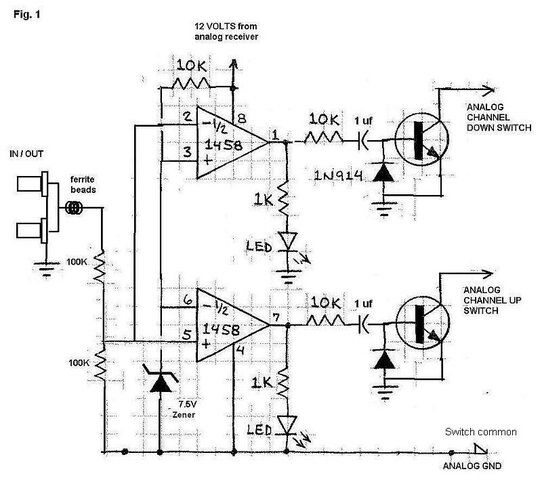

For those using an analog receiver to control the feed servo for polarity control.

Here's something I've been brainstorming. Programmed with a soldering iron.

A Work in progress. Anyone have any comment?

Theory:

LNB voltage is divided by equal resistances to equal 1/2 the LNB voltage. This will result in approx 6.5 and 9 volts applied to the comparators.

The other input to the comparators is clamped to 7.5 to 8 volts by a zener. This will result in one or the other comparator output being high.

This will turn on the corosponding LED and momentarily cause the associated transistor to conduct as the capacitor in its base lead charges.

The open collector outputs will appear as a momentary short to ground.

The reversed diode, base to emitter, discharges the capacitor when the comparator output goes low. This should ensure switching at rapid rates of channel change.

Will require further output circuitry if the channel UP / DOWN of the analog receiver is matrixed, and does not use ground as common.

Here's something I've been brainstorming. Programmed with a soldering iron.

A Work in progress. Anyone have any comment?

Theory:

LNB voltage is divided by equal resistances to equal 1/2 the LNB voltage. This will result in approx 6.5 and 9 volts applied to the comparators.

The other input to the comparators is clamped to 7.5 to 8 volts by a zener. This will result in one or the other comparator output being high.

This will turn on the corosponding LED and momentarily cause the associated transistor to conduct as the capacitor in its base lead charges.

The open collector outputs will appear as a momentary short to ground.

The reversed diode, base to emitter, discharges the capacitor when the comparator output goes low. This should ensure switching at rapid rates of channel change.

Will require further output circuitry if the channel UP / DOWN of the analog receiver is matrixed, and does not use ground as common.