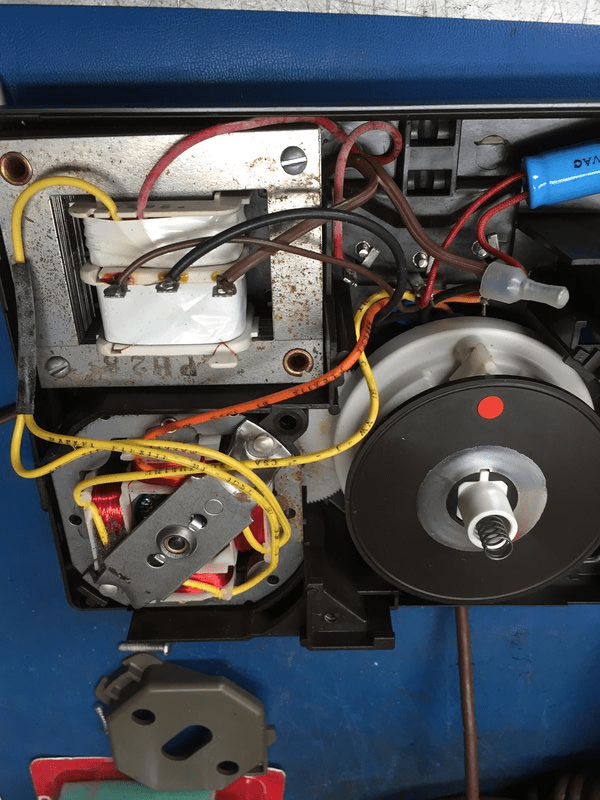

Crazy stuff. It went together, it's got to come apart. Worst case cut the corner retainers and lift the pieces out. Snip the pins and use screws where they were.

Look at it carefully. If the knob were loosened would the whole top with the yellow thingys come out as one unit?

Look at it carefully. If the knob were loosened would the whole top with the yellow thingys come out as one unit?