Sorry guys, I'm having trouble getting the pictures from my folder onto the website. I'll keep experimenting when I have time.

Primestar Dish on SG2100 ?

- Thread starter PipeDream

- Start date

- Latest activity Latest activity:

- Replies 145

- Views 40K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Please reply by conversation.

O.K. everybody, I need help/  I got my SG2100 motor, mounted on the mast perfectly level, pointed to what I'm pretty sure true south. I put the primestar dish on, and set to what I believe is the correct elevation. I have a fortec star lifetime ultra reciever. I didn't have any luck finding the satellite at 97 degrees W. Zipcode is 58416. I manually located G3C, and stored that in the receiver. This dish moves to the correct position when I find one of this satellites channels (CCTV channels). But I can't make the dish find any other satellites. In the antenna setup menu, I have the positioner setting on "1.2". Everytime I change the setting to USALS, the dish moves, and I can't find anything. Please help!!

I got my SG2100 motor, mounted on the mast perfectly level, pointed to what I'm pretty sure true south. I put the primestar dish on, and set to what I believe is the correct elevation. I have a fortec star lifetime ultra reciever. I didn't have any luck finding the satellite at 97 degrees W. Zipcode is 58416. I manually located G3C, and stored that in the receiver. This dish moves to the correct position when I find one of this satellites channels (CCTV channels). But I can't make the dish find any other satellites. In the antenna setup menu, I have the positioner setting on "1.2". Everytime I change the setting to USALS, the dish moves, and I can't find anything. Please help!!  :shocked

:shocked

EDIT: If IA-5 at 97W is my true south satellite, can someone give me the coordinates for the test channel to look for?

:shocked

:shocked EDIT: If IA-5 at 97W is my true south satellite, can someone give me the coordinates for the test channel to look for?

The motor elevation should be 42 deg. (Remember one side is marked Elelvation and the other Latitude)

Dish elevation should be 23 deg. (Or whatever brings in the peak signal quality)

I would find and store a channel/TP. on IA-5 as its closer to your true south.

DFreq : 12175MHz (V) SR : 22.998Msps

Dish elevation should be 23 deg. (Or whatever brings in the peak signal quality)

I would find and store a channel/TP. on IA-5 as its closer to your true south.

DFreq : 12175MHz (V) SR : 22.998Msps

Pete:

I just completed the installation of an old Primestar dish on an SG2100 motor and it works great.

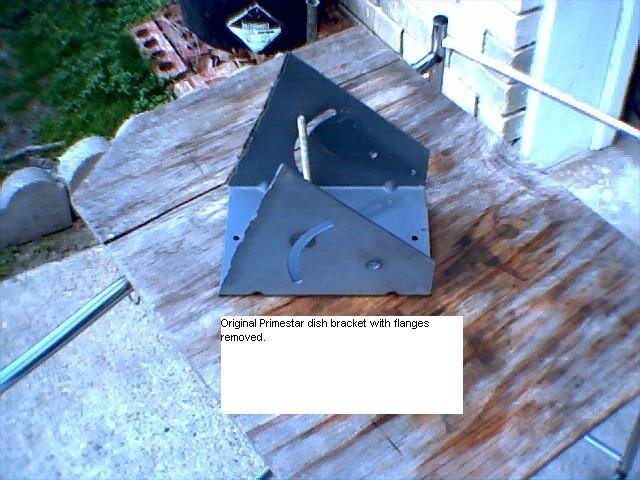

1. I removed the existing mount from the dish.

2. Then I cut off the flange on each side just an eighth inch or so past the bend so it would be more rigid.

3. I bolted the flanges on the top and bottom using the same mounting holes. Now they ran horizontal instead of vertical, and the curved edges faced each other and were turned in toward the dish.

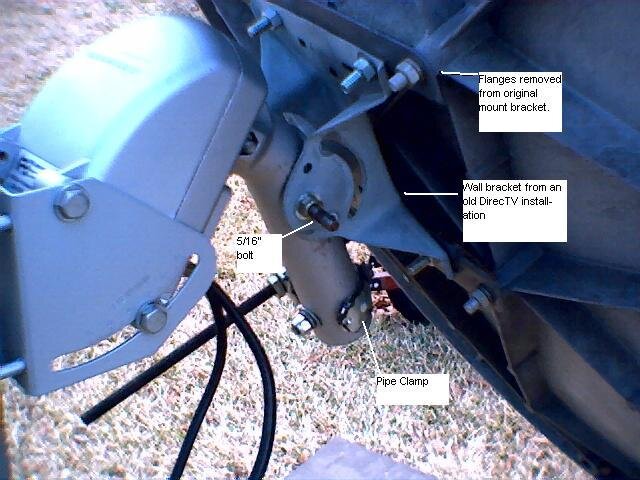

4. I knew that it was important to mount the dish as "square" as possible to the motor arm so that it would track properly. I solved this problem by removing the wall mounting bracket from an old DirecTv installation. I centered it on the flanges and drilled holes through the flanges using the holes in the wall bracket as a guide.

5. The pivot hole in the wall bracket was only one-quarter inch but the holes in the upper part of the motor arm was five-sixteenths, so I drilled out the pivot holes to match. This was necessary to keep the dish from flopping over to one side when going to a far-west position.

6. I soon found out that I needed a jackscrew in order to make fine tuning adjustments to the dish elevation. I used a one-and-a-half inch pipe clamp (looks like a question mark without the dot underneath), fairly rigid, and marked the motor arm where it needed to be mounted. I used a three-eighths inch bolt as a jackscrew and ran it through the hole in the pipe clamp. I placed a jam nut on each side of the clamp.

7. I had to remove the dish and the motor arm and use a drill press to drill a five-sixteenths inch hole through both the pipe clamp and the motor arm. I then used a bolt about two inches long to mount the clamp.

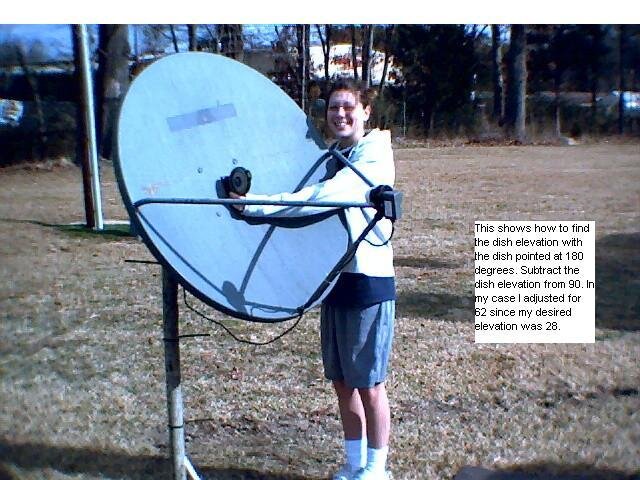

8. That completed the retrofit and it worked great. The booklet that came with the motor has a chart on page seven that lists the declination angles and the resulting dish elevation for each degree of latitude. Mine was 28 degrees, but the wall bracket that I used had no scale on it. I used my angle finder on the front of the dish in that flat area right in the center. By subtracting 28 from ninety I knew when I had the approximate dish elevation when it was pointed due south.

9. Then it was just a matter of zeroing in the adjustments. I had a little trouble there too. My pole was a galvanized 2 inch pipe that had been painted over. When I loosened the U-bolts to the point that I could rotate the motor easily without jerking and overshooting, it tended to walk down the pole. I cut the coupling portion off a 2 inch PVC pipe, split it lengthwise, and placed the halves against the bottom of the motor. I used a hose clamp to secure them. I still could not loosen the motor as much as I wanted because it would start to tilt forward. So I had to snug it up. I placed a piece of tape on the pipe and made a pencil mark on the tape and another on the U-bolt cleat. Then I could see how much I had turned it. Soon, I located my true south satellite.

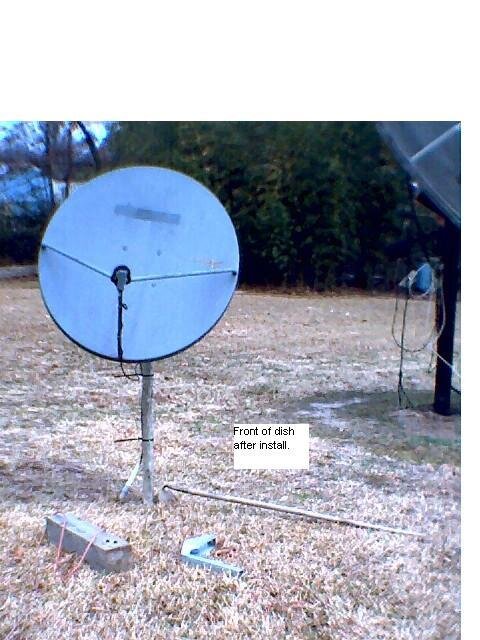

10. It tracks all satellites great.

Old John

I just completed the installation of an old Primestar dish on an SG2100 motor and it works great.

1. I removed the existing mount from the dish.

2. Then I cut off the flange on each side just an eighth inch or so past the bend so it would be more rigid.

3. I bolted the flanges on the top and bottom using the same mounting holes. Now they ran horizontal instead of vertical, and the curved edges faced each other and were turned in toward the dish.

4. I knew that it was important to mount the dish as "square" as possible to the motor arm so that it would track properly. I solved this problem by removing the wall mounting bracket from an old DirecTv installation. I centered it on the flanges and drilled holes through the flanges using the holes in the wall bracket as a guide.

5. The pivot hole in the wall bracket was only one-quarter inch but the holes in the upper part of the motor arm was five-sixteenths, so I drilled out the pivot holes to match. This was necessary to keep the dish from flopping over to one side when going to a far-west position.

6. I soon found out that I needed a jackscrew in order to make fine tuning adjustments to the dish elevation. I used a one-and-a-half inch pipe clamp (looks like a question mark without the dot underneath), fairly rigid, and marked the motor arm where it needed to be mounted. I used a three-eighths inch bolt as a jackscrew and ran it through the hole in the pipe clamp. I placed a jam nut on each side of the clamp.

7. I had to remove the dish and the motor arm and use a drill press to drill a five-sixteenths inch hole through both the pipe clamp and the motor arm. I then used a bolt about two inches long to mount the clamp.

8. That completed the retrofit and it worked great. The booklet that came with the motor has a chart on page seven that lists the declination angles and the resulting dish elevation for each degree of latitude. Mine was 28 degrees, but the wall bracket that I used had no scale on it. I used my angle finder on the front of the dish in that flat area right in the center. By subtracting 28 from ninety I knew when I had the approximate dish elevation when it was pointed due south.

9. Then it was just a matter of zeroing in the adjustments. I had a little trouble there too. My pole was a galvanized 2 inch pipe that had been painted over. When I loosened the U-bolts to the point that I could rotate the motor easily without jerking and overshooting, it tended to walk down the pole. I cut the coupling portion off a 2 inch PVC pipe, split it lengthwise, and placed the halves against the bottom of the motor. I used a hose clamp to secure them. I still could not loosen the motor as much as I wanted because it would start to tilt forward. So I had to snug it up. I placed a piece of tape on the pipe and made a pencil mark on the tape and another on the U-bolt cleat. Then I could see how much I had turned it. Soon, I located my true south satellite.

10. It tracks all satellites great.

Old John

Sorry Pete,

I have neither a digital camera nor a scanner. If I can find a neighbor with a digital camera I will post a pix or two, If I can find one with a Polaroid I'll take pictures and mail them to you.

I tried to make the description as clear as possible, but a picture would help.

Perhaps someone will post some specific questions and I can see where I failed to describe the job properly.

Old John

I have neither a digital camera nor a scanner. If I can find a neighbor with a digital camera I will post a pix or two, If I can find one with a Polaroid I'll take pictures and mail them to you.

I tried to make the description as clear as possible, but a picture would help.

Perhaps someone will post some specific questions and I can see where I failed to describe the job properly.

Old John

Many places now offer to digitize film that is bought in. Neighbors may have a scanner if they don't have a camera?

Good luck and thanks for the postings.

Good luck and thanks for the postings.

dirtyshame said:Sorry Pete,

I have neither a digital camera nor a scanner. If I can find a neighbor with a digital camera I will post a pix or two, If I can find one with a Polaroid I'll take pictures and mail them to you.

I tried to make the description as clear as possible, but a picture would help.

Perhaps someone will post some specific questions and I can see where I failed to describe the job properly.

Old John

Ken:

We're mostly old retired folks in this neighborhood and I'm about the only one who even owns a computer. One neighbor has a daughter who lives about 100 miles away who he thinks has a digital camera. He is supposed to ask her to bring it on her next visit. I'm not counting on that though, at our age we are forgetful, he more so than I. I will keep asking around.

I have one of those little cameras that use a round disk that takes about 16 pictures although the focus isn't great. But if I have to I'll try that and then have it digitized and send it in to Satellite Guys and y'all can decide which ones you want to show. Does Office Depot do digitizing?

Old John

We're mostly old retired folks in this neighborhood and I'm about the only one who even owns a computer. One neighbor has a daughter who lives about 100 miles away who he thinks has a digital camera. He is supposed to ask her to bring it on her next visit. I'm not counting on that though, at our age we are forgetful, he more so than I. I will keep asking around.

I have one of those little cameras that use a round disk that takes about 16 pictures although the focus isn't great. But if I have to I'll try that and then have it digitized and send it in to Satellite Guys and y'all can decide which ones you want to show. Does Office Depot do digitizing?

Old John

You can take the pictures (prints) to just about anybody that sells computers and probably get them scanned to a floppy disk. I believe that Fedex Kinkos will also do this, although I've never tried...

I've seen a cheap-o Philips digital camera on a keychain, probably about $20 or so at Wal Mart. The same camera with somebody else's name on it was available at one of the major department stores, Belk I think.

Just aim and click. Because it's so cheap, there's no display, the only way to know if your pics are any good is to look at them on your computer.

I hope you can get some pictures of this uploaded. I'm having trouble envisioning steps 2 thru 6 in my head.

Just aim and click. Because it's so cheap, there's no display, the only way to know if your pics are any good is to look at them on your computer.

I hope you can get some pictures of this uploaded. I'm having trouble envisioning steps 2 thru 6 in my head.

Pepper,

I'll go to Wal-Mart tomorrow, they are only 4 miles from here and they are one of the Super stores. If they have them here I'll get one and send photos as soon as possible.

Old John

I'll go to Wal-Mart tomorrow, they are only 4 miles from here and they are one of the Super stores. If they have them here I'll get one and send photos as soon as possible.

Old John

I bought one of the digital cameras but the software doesn't match the camera. I took some pictures but the software would only let me take snapshots of live action while it was connected by its USB cable. Will try again tomorrow. The booklet mentions a menu that never appears. Tried re-installing it 3 times.

Old John

EDIT: 12/30/5 Got a new camera today and it works pretty good for a $20 camera!

Old John

EDIT: 12/30/5 Got a new camera today and it works pretty good for a $20 camera!

Attachments

-

Dec30^01.JPG55.5 KB · Views: 656

Dec30^01.JPG55.5 KB · Views: 656 -

Jan01$13.JPG52.4 KB · Views: 601

Jan01$13.JPG52.4 KB · Views: 601 -

Jan01$11.JPG65.5 KB · Views: 709

Jan01$11.JPG65.5 KB · Views: 709 -

Dec30^07.JPG90 KB · Views: 599

Dec30^07.JPG90 KB · Views: 599 -

Dec30^06.JPG81.9 KB · Views: 614

Dec30^06.JPG81.9 KB · Views: 614 -

Dec30^05.JPG56 KB · Views: 719

Dec30^05.JPG56 KB · Views: 719 -

Dec30^04.JPG69.1 KB · Views: 615

Dec30^04.JPG69.1 KB · Views: 615 -

Dec30^03.JPG56.2 KB · Views: 770

Dec30^03.JPG56.2 KB · Views: 770 -

Dec30^02.JPG56.5 KB · Views: 1,261

Dec30^02.JPG56.5 KB · Views: 1,261

Last edited:

Thanks for the taking the photos. Now I just need to find this dish. Like I need another dish

dirtyshame said:I bought one of the digital cameras but the software doesn't match the camera. I took some pictures but the software would only let me take snapshots of live action while it was connected by its USB cable. Will try again tomorrow. The booklet mentions a menu that never appears. Tried re-installing it 3 times.

Old John

EDIT: 12/30/5 Got a new camera today and it works pretty good for a $20 camera!

My first camera was a Digital (brand) camera . It was a "web camera" that you could send live action photos with. I didn't know the terminology so I bought it by mistake. The second camera was an Argus brand and it is very simple to operate.

Those old Primestar dishes are hard to find, possibly because they are easy to remove. I'll keep my eyes open for another one for my brother.

They pick up all the satellites very well.

Old John

Those old Primestar dishes are hard to find, possibly because they are easy to remove. I'll keep my eyes open for another one for my brother.

They pick up all the satellites very well.

Old John

yeah, that's a great job. I didn't realize till I saw the pics that we were talking about the round PrimeStar dish. The same thing would probably work for the ovals as well, I think the mounts are all the same.

Pepper said:yeah, that's a great job. I didn't realize till I saw the pics that we were talking about the round PrimeStar dish. The same thing would probably work for the ovals as well, I think the mounts are all the same.

They're not quite the same. The mounts on the semi-round (they're actually elliptical and a bit taller than wider) are larger and much heavier than the mounts on the oval (wider than taller) primestars. If you mount one of the small oval primestars (like a 40 x 30) on a motor like the Sg2100, it's probably okay and easiest to just use the original primestar mount and adapt it to fit the shaft of the motor, but with the larger round ones like this you probably need to make your own mount as dirtyshame has done because the original mount for those is much too heavy and might siginificantly shorten the life of the motor.

Last edited:

The dish is 39.5 x 43. I didn't realize that it looked round until I read the above posts. The motor says it will handle up to 1.2M dishes, but the weight of the primestar mount was just too much, and it would have been difficult to attach to the motor arm and maintain the proper alignment and fine adjust.

I didn't know Primestar made more than 1 size until I read these posts.

Old John

I didn't know Primestar made more than 1 size until I read these posts.

Old John

Last edited:

I should upload some pics of how I did my oval Primestar. I took the skew plate from a dish 500, turned the tube part upside down, and bolted it to the two top bolts on the dish. I had to shim the bottom with whatever I could find lying around that would fit in the gap, which just happened to be an old crimp tool I don't use anymore. Before it all falls apart I should replace it with something more sturdy.

Edit: I retrieved my tool and replaced it with a 6-inch piece of metal that came from "somewhere", fits better but still no more sturdy. Amazing it's lasted this long.

Edit: I retrieved my tool and replaced it with a 6-inch piece of metal that came from "somewhere", fits better but still no more sturdy. Amazing it's lasted this long.

Last edited:

I had been wondering if it might be possible to use a larger primestar dish with a smaller motor for a few weeks now until a friend then refered me to this fantastic site. In thanks for the inspiration, I offer up the pics of what I have attemted to do in hopes someone might benefit from them. It is currently untested, but I have faith it will work just fine. All aspects should be adjustable with this way of doing it.

Its a combo of what I have seen discussed so far in this thread. I started with the principals of Ziploc's method, using the angle brackets, but upon finding that the measurements of my dish were larger than in Ziploc's plan, I had to rethink the entire project.

So yes, of course that meant I had to go drive back to the store, buy a new piece of angle bracket, and start over. My mount holes were square, 7" on center. Its the large mostly round primestar dish - 36"x39".

Anyway. I went back to this thread to see if I missed something and realized I had. It was more than one page long (ARRRGh how did I miss that!!!!), and was inspired by hearing of others using standard mounting hardware from other dishes to pull this off.

SOooo I hacked away at a mount from a 3-phase D-tv dish. So now (like I need it), I have skew as well as elevation.

I first cut off the arm of the old dish, and then I decided to take it a little further and cut off a little more of the non-essential area to lighten the load a little further.

I did have to change the way I arranged the angle-brackets, and then I had to shim one bracket out with some nuts to line it up with the D-tv mount. It was fairly very difficult to tighten down the nuts on the DTV mount because of the way the angle brackets fit together, but it did finally work.

The end result is REALLY solid, and looks very good as well. I just need to test it on a day without blizzard conditions so that I won't fall off the roof. So the results probably won't be for a couple days. For now, enjoy the pics.

Its a combo of what I have seen discussed so far in this thread. I started with the principals of Ziploc's method, using the angle brackets, but upon finding that the measurements of my dish were larger than in Ziploc's plan, I had to rethink the entire project.

So yes, of course that meant I had to go drive back to the store, buy a new piece of angle bracket, and start over. My mount holes were square, 7" on center. Its the large mostly round primestar dish - 36"x39".

Anyway. I went back to this thread to see if I missed something and realized I had. It was more than one page long (ARRRGh how did I miss that!!!!), and was inspired by hearing of others using standard mounting hardware from other dishes to pull this off.

SOooo I hacked away at a mount from a 3-phase D-tv dish. So now (like I need it), I have skew as well as elevation.

I first cut off the arm of the old dish, and then I decided to take it a little further and cut off a little more of the non-essential area to lighten the load a little further.

I did have to change the way I arranged the angle-brackets, and then I had to shim one bracket out with some nuts to line it up with the D-tv mount. It was fairly very difficult to tighten down the nuts on the DTV mount because of the way the angle brackets fit together, but it did finally work.

The end result is REALLY solid, and looks very good as well. I just need to test it on a day without blizzard conditions so that I won't fall off the roof. So the results probably won't be for a couple days. For now, enjoy the pics.

Attachments

Last edited:

- Status

- Please reply by conversation.

Similar threads

- Replies

- 0

- Views

- 331

- Replies

- 8

- Views

- 953

- Replies

- 1

- Views

- 634

- Replies

- 6

- Views

- 748