well my neighbor and I began putting up my new 4' fortec offset dish on my roof. we bolted it on to the roof securely. the pitch is pretty steep so i had to place 3" piece of wood under the lower two legs. when i check the pole before slipping the dish down it, the pole is straight vertically, when the dish goes on it with the SG380 motor, the pole ends up about 1/8" crooked! I guess from weight of the dish? anyways we can't get any sat when we move the dish towards 72 and 74W I don't get anything via the meter...shouldn't my elevation be 42.1? should we aim the dish at my true south which I think is 180.9 or magnetic south 194.6, oh by the way my location is 41.4 latitude, longitude is 73.4 (CT)...if I can't straighten the pole , can I compensate the elevation of the dish? BTW...I will using a KU LNB to aim the dish and plan to later attach a C-Band lnb with conical scaler in the center and move the KU band to the side on a sidecar. thanks much!

Set up questions with my 1.2 m FTA dish

- Thread starter dfecarter

- Start date

- Latest activity Latest activity:

- Replies 22

- Views 4K

-

ENJOY SATELLITEGUYS AD FREE THIS FEBRUARY!

Thank you to the very generous support we got from our members in December we have decided to make the month of February AD FREE for everyone!

We want to see the true speed of our site and enjoy SatelliteGuys the way it was meant to be enjoyed!

If you would like to help us keep the lights on and keep enjoying the site AD FREE consider becoming a PUB MEMBER by CLICKING HERE.

THANK YOU TO EVERYONE FOR YOUR SUPPORT!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Please reply by conversation.

You may not set the 4' dish at roof as it may too heavy on to the roof or you may only drill through the plywood and not to the stud, which is not secured at all. From the information you provided, I think you better relocate the dish to some place where more stable to the dish.

Is it the pole bending, or is the surface it's mounted to giving way? Either way, if the pole leans south with the dish south, the lean may follow the direction of the dish. I.E. Leans east with dish moved east and west when dish goes west. I don't think there is an easy fix for a insecure pole. Also, I'd be very concerned about wind load. I do know of an installation (C band 10 ft, now disassembled ) where the pole was passed through the roof, attic, a second floor wall, and terminated at the second floor. Required extensive reinforcement of the roof joists. A 4 ft dish would require less, but would be the way I'd do it. At least through the roof and terminate at the attic floor.

your mounting post and motor assembly must be 100% level at ALL TIMES.....you can not compensate for this with dish or motor adjustments....if they are not 100% level then anything you do past this point will just be a big huge waste of time....trust me ive been there and done that....and i do mean 100% level and not one degree off....

a well mounted post should easily be able to support your entire body weight without moving....it is not just the weight of the dish and motor.....the post is also supporting against wind resistance.....and with a dish that size the wind force can be very strong.....

for these reasons its always best to mount on a concrete block or brick wall....or a cemented post at least 4 feet into the ground....

i would never even attempt to mount a post the way you are doing it because i know right away it will never be strong enough and secure enough....

the only way i would mount a dish on your roof like that would be using a non-penetrating roof mount that uses concrete cinderblocks to hold it down in place....no drilling or screws nessessary....

like this......

http://www.sadoun.com/Sat/Products/Install/NPR4A-roof-mount.htm

a well mounted post should easily be able to support your entire body weight without moving....it is not just the weight of the dish and motor.....the post is also supporting against wind resistance.....and with a dish that size the wind force can be very strong.....

for these reasons its always best to mount on a concrete block or brick wall....or a cemented post at least 4 feet into the ground....

i would never even attempt to mount a post the way you are doing it because i know right away it will never be strong enough and secure enough....

the only way i would mount a dish on your roof like that would be using a non-penetrating roof mount that uses concrete cinderblocks to hold it down in place....no drilling or screws nessessary....

like this......

http://www.sadoun.com/Sat/Products/Install/NPR4A-roof-mount.htm

Last edited:

I had a similar problem with an 80cm dish mounted on the roof. For that LITTLE dish, I braced the underside of the roofing plywood with 2x6" pieces nailed between the trusses to form a rigid base for the mount. I can't imagine this technique working for a 4 foot dish, and after having one dish on the roof, I've never put up another. One thing to remember on motorized dishes, they are not "set it and forget it". You will always be tinkering with something. Bring that dish down where you can get to it, and have a solid mount.

One thing to remember on motorized dishes, they are not "set it and forget it". You will always be tinkering with something.

i know what you mean but i dont really agree with that....i think it all depends on how well you mount it and how much time you take to make sure things are done properly....i am a "take your time" type of guy and like to do things properly....

at my last house i had a 36 inch fortec on an SG2100 motor on top of my roof that was 3 stories up....it was there for 3 years and i never had to touch it once....which was good because the dish was basically not accessible all winter long....and we get very cold winters here too....i took about 4 full days putting that dish up to make sure it was done right....

when i moved to my new house it broke my heart to take that dish down because it was setup so damn perfect.....now i have a 39 incher on an SG9120 at my new place that i setup in the summer....we will see how long this one lasts without an adjustments....

If you can get the pole stable and properly supported for the weight of the motor/dish/lnb I'm sure you can figure out a way to get it tracking properly. the problem will be as brent eluded, what are you going to do when the dish needs tweeking? it doesn't take much for your dish to become out of alignment. Cband on the minibud is usually not just set it and forget it and ultimately your lack of access to make adjustments will likely end up in disappointment.

the only way i would mount a dish on your roof like that would be using a non-penetrating roof mount that uses concrete cinderblocks to hold it down in place....no drilling or screws nessessary....

like this......

Better option for peaked roof NPRM Peak NPRM

Buy from a site sponsor and save $$$$$ - Flat Roof NPR4A NPRM

I just purchased and installed a WS 1.2 meter dish about a month ago and I had the same problem. The mount was too big and the dish was too big for a frame house to adequately stabilize it. After doing everything and getting it level within a few days I was a half bubble off on the level and no matter how I shimmed it I could not fix it. I took it down off the roof and spent $20 for a 8' fence corner post and 5 bags of concrete and used a post hole digger. The problem was fixed and the dish is rock solid now. The only thing I had to do is cut down a few more trees and then I put my 90cm dish/motor back on the roof to cover the few sats I can't get from the ground. Either get a heavy duty mount as Brian said or go with a ground mount.

You will have to re-engineer your roof mounting setup to prevent any movement in the mast. Even the silghtest error is going to cause you problems either right off the bat or in the near future. This can be accomplished, but you will have to commit yourself to not skimping on any materials or cutting any corners.

However, the absolute BEST method to install a motorized dish when you start getting into these dish sizes is on a mast at ground level, footed in concrete.

The NPRM that SatelliteAV mentioned might be worth looking into, but as others stated, you will always want to tinker with the dish at first until you have it perfected. Having the dish at ground level will save you so many headaches and hassles. Especially since you have a steep pitch roof. Climbing up there over and over again will grow tiresome quickly.

I use galvanized water pipe 1-1/2" to 2" size, NOT galvanized tubing. Galvanized water pipe is thick walled and won't flex or bend/buckle under heavy winds and you won't crush it with the mountng brackets. Attaching "Tee" fittings and short nipple pipes at the bottom, within the concrete, will prevent the mast from turning in the concrete. I auger a 14"-16" hole in the ground at least 36" in depth. 48" might be better, depending upon how cold your winters are. You want the base of the concrete to be well below the frost line. If not, then when the thaw goes out in the spring, the ground will "heave" and your mast will no longer be plumb and your alignments will all be off.

Another thought for you to ponder is that, unless you have a tall two story home, you truly are not gaining a great deal of LOS availability by installing a roof mounted dish (in most cases). The arc of the satellites is much higher in the sky than you realize. Any trees or nearby buildings that you suspect are occluding your LOS are probably not really in the way as much as you think. My latitude is 41.6°N, therefore I have a good notion regarding how high the sats are in your sky. They are the same as mine.

It is too bad that the SOLAR OUTAGE PERIOD has passed us by. You missed it by one month (roughly). This is when the sun's path follows the same path as all the satellites. On certain days in the spring and then again in the fall, you can go outside and observe the position of the sun and see where any specific satellite is located on the horizon. Using this information, you can go to several locations in your yard and detect whether any particular satellite will be blocked by a tree or a building. Unless you live in a forest with many great trees, you would be amazed at how much clearance for LOS you actually have.

You might still be able to utilize this tool now, but you will have to remember that the sun's track will be below the actual satellite(s) by a few degrees. In other words, it won't be perfect, but it might provide you with a loose indication of what your LOS might be. Check here: http://www.satellite-calculations.com/SUNcalc/SUNcalc.htm

RADAR

However, the absolute BEST method to install a motorized dish when you start getting into these dish sizes is on a mast at ground level, footed in concrete.

The NPRM that SatelliteAV mentioned might be worth looking into, but as others stated, you will always want to tinker with the dish at first until you have it perfected. Having the dish at ground level will save you so many headaches and hassles. Especially since you have a steep pitch roof. Climbing up there over and over again will grow tiresome quickly.

I use galvanized water pipe 1-1/2" to 2" size, NOT galvanized tubing. Galvanized water pipe is thick walled and won't flex or bend/buckle under heavy winds and you won't crush it with the mountng brackets. Attaching "Tee" fittings and short nipple pipes at the bottom, within the concrete, will prevent the mast from turning in the concrete. I auger a 14"-16" hole in the ground at least 36" in depth. 48" might be better, depending upon how cold your winters are. You want the base of the concrete to be well below the frost line. If not, then when the thaw goes out in the spring, the ground will "heave" and your mast will no longer be plumb and your alignments will all be off.

Another thought for you to ponder is that, unless you have a tall two story home, you truly are not gaining a great deal of LOS availability by installing a roof mounted dish (in most cases). The arc of the satellites is much higher in the sky than you realize. Any trees or nearby buildings that you suspect are occluding your LOS are probably not really in the way as much as you think. My latitude is 41.6°N, therefore I have a good notion regarding how high the sats are in your sky. They are the same as mine.

It is too bad that the SOLAR OUTAGE PERIOD has passed us by. You missed it by one month (roughly). This is when the sun's path follows the same path as all the satellites. On certain days in the spring and then again in the fall, you can go outside and observe the position of the sun and see where any specific satellite is located on the horizon. Using this information, you can go to several locations in your yard and detect whether any particular satellite will be blocked by a tree or a building. Unless you live in a forest with many great trees, you would be amazed at how much clearance for LOS you actually have.

You might still be able to utilize this tool now, but you will have to remember that the sun's track will be below the actual satellite(s) by a few degrees. In other words, it won't be perfect, but it might provide you with a loose indication of what your LOS might be. Check here: http://www.satellite-calculations.com/SUNcalc/SUNcalc.htm

RADAR

Last edited:

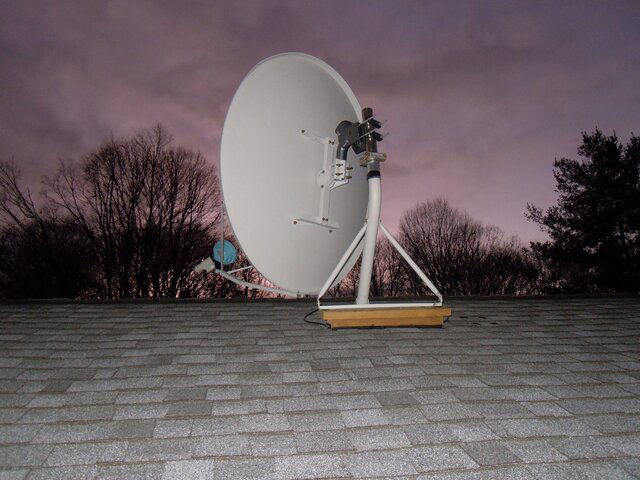

Thanks for the feedback all. I agree a ground mount would provide more stability and the benefit of easy access. But unfortunately I since I live on a small half acre lot surrounded by plenty of trees so the roof is my only option. I did operate, very successfully a 36" motorized fta dish in this same spot - it worked flawlessly for the past 2 years. Attached are some pics of the 4' dish, showing the roof mount.

Attachments

The only way that this tripod mast will stay level is that the build-up lumber and mast footer must be lagged into the rafters. The current mounting appears to only be secured into the roofing / sheeting. This will not support the weight let alone the wind load as previously mentioned.

Spreading the weight and wind load across two or three rafters (roof joists) with several pressure treated 2x6 might provide adequate support for the existing tripod mast legs and footer.

Spreading the weight and wind load across two or three rafters (roof joists) with several pressure treated 2x6 might provide adequate support for the existing tripod mast legs and footer.

You get your first good windstorm leaving your dish like that and you going to wish you did it differently. That dish is a huge sail and if the wind catches it right it's going to pull right up out of the sheathing and take a good portion of your roof along with it. In addition it looks like all three supports are in a single plane. As Brian said the load needs to be spread out over a couple of rafters at a minimum.

Been working on the project a bit today...feel as if I'm making progress, have added bolts going through roof with 1/2" plywood added on the underside and welded the two poles sections together, now the pole is better, the bubble is within both lines, both before and after dish was clamped to pole...tomorrow my neighbor may help me aim dish at some sats.. have aimed at 193 deg my mag south, did a scan of 74w got 4 transponders but no real signal, also my brand new SG380 motor isn't moving at all! any thoughts, pressed reset button nothing, don't see a green light on this motor...should I? my SG2100 had green light.

now the pole is better, the bubble is within both lines, both before and after dish was clamped to pole

one thing to keep in mind....its not the pole that has to be level....its the motor...and just because the pole is level that does not guarantee that the motor will be!!

motor brackets can bend or twist if you overtighten the mounting bolts...so its best to check and see if the motor itself is level...

put a level accross the motors bracket to see if it is level....straight accross back and front and corner to corner....

Been working on the project a bit today...feel as if I'm making progress, have added bolts going through roof with 1/2" plywood added on the underside and welded the two poles sections together, now the pole is better, the bubble is within both lines, both before and after dish was clamped to pole...tomorrow my neighbor may help me aim dish at some sats.. have aimed at 193 deg my mag south, did a scan of 74w got 4 transponders but no real signal, also my brand new SG380 motor isn't moving at all! any thoughts, pressed reset button nothing, don't see a green light on this motor...should I? my SG2100 had green light.

is it possible you have the cable connections reversed to the motor...

The SG2100 is marked to show which cable to plug in were.

Yes it is possible to have reversed cable.

Good luck with your install.

Yes it is possible to have reversed cable.

Good luck with your install.

is it possible you have the cable connections reversed to the motor...

No I didn't have the LNB and Rec cables crossed up but I did have the Sat In line connected to the Ant In and not to the LNB In on the back if my Fortec receiver! What a dope! So I fixed that blunder and the motor is working fine now!

So we finally found stuff from 72W (my true south) or 0 position but still need to fine tune because when I travel any distance to the west and east and try the sats I should be getting...once I get past 87W the reception is sketchy. Reduced signal strength or not getting chs. at all. Plus I know my motor latitude or dish elevation is off because when i scanned 103W I get BVN from 101W, there are other such occurances. So I loose some of the clark belt when the dish moves and rotates! After I get the KU LNB good, we plan on trying the KU/C Band combo LNB (CK1) and compare KU reception. If I don't loose much I'll stick with the combo.If not, I'll try the sidecar LNB attachment, with combo lnb in center(only using the C band though) and KU off center on the sidecar. Will let you know what I end up doing and the success with it.

BTW, the dish seems very solid and dish motor quite vertical so far.

So we finally found stuff from 72W (my true south) or 0 position but still need to fine tune because when I travel any distance to the west and east and try the sats I should be getting...once I get past 87W the reception is sketchy. Reduced signal strength or not getting chs. at all. Plus I know my motor latitude or dish elevation is off because when i scanned 103W I get BVN from 101W, there are other such occurances. So I loose some of the clark belt when the dish moves and rotates! After I get the KU LNB good, we plan on trying the KU/C Band combo LNB (CK1) and compare KU reception. If I don't loose much I'll stick with the combo.If not, I'll try the sidecar LNB attachment, with combo lnb in center(only using the C band though) and KU off center on the sidecar. Will let you know what I end up doing and the success with it.

BTW, the dish seems very solid and dish motor quite vertical so far.

No I didn't have the LNB and Rec cables crossed up but I did have the Sat In line connected to the Ant In and not to the LNB In on the back if my Fortec receiver! What a dope! So I fixed that blunder and the motor is working fine now!

Dfecarter,

Sometimes such errors can be easier to make than you think. I have an AZBox Premium and an AZBox Premium PLUS. The tuners in each are different in several ways, but one of the more misleading differences is that the IF IN and the LOOP OUT connectors on the tuners have been swapped in position. If I get in a hurry and forget which receiver I am hooking up, it is easy to err and reverse the cable connection. It does no harm, but if you are sleepy or maybe imbibing a little in the spirits, it can leave you scratching your head for a moment.

It is good that you figured out the error. Don't feel bad about a silly mistake, just make sure that you learn from it. That is almost inevitable - learning from our mistakes. It seems that you learn so much more when you do things wrong then you do if you have perfect instructions to do things right.

So we finally found stuff from 72W (my true south) or 0 position but still need to fine tune because when I travel any distance to the west and east and try the sats I should be getting...once I get past 87W the reception is sketchy. Reduced signal strength or not getting chs. at all. Plus I know my motor latitude or dish elevation is off because when i scanned 103W I get BVN from 101W, there are other such occurances. So I loose some of the clark belt when the dish moves and rotates!

Yes, you will need to expend some time and thought to get it set perfectly. Just remember one little rule... Don't try to be too perfect, or too greedy with the signal quality on any particular satellite. Many people make the mistake of trying to peak the signal on every satellite they drive the dish to. This is the wrong approach. Setting up your motorized dish to track the arc is a calibration process. In such a process, you have to go back and forth between several points and make small adjustments to "merely improve" the signal quality at each point, a little at a time.

A good example is a three-point calibration process. Point #1 would be your true south sat. Points #2 and #3 would be the furthest west and the furthest eat satellite that you can get a signal from. Once you get all three points optimized, then you expand your horizon, literally! Then you pick two new east and west satellites further east and west from the first two and re-optimize your signal quality between all three points again. You keep advancing and expanding your total horizon until you cover the whole sky.

It sounds like a slow and tedious process, but it is much faster and more accurate than doing it any other way. Once you develop a feel for it, it will simply just click for you without even thinking about it. Have you ever watched Bob Ross paint on PBS? See how easy and relaxed he is and how beautiful his paintings turn out? It is the same thing for aligning your motorized dish.

After I get the KU LNB good, we plan on trying the KU/C Band combo LNB (CK1) and compare KU reception. If I don't loose much I'll stick with the combo.If not, I'll try the sidecar LNB attachment, with combo lnb in center(only using the C band though) and KU off center on the sidecar. Will let you know what I end up doing and the success with it.

BTW, the dish seems very solid and dish motor quite vertical so far.

Incorporating C and Ku band on the same dish, a small dish or "mini-bud" will prove to be a challenge. Fairly easy with a fixed point dish, but not so much with a motorized dish meant for Ku-Band. It is a fun project, but don't expect too much. It is more for the fun and the learning experience.

I am eager to hear of your future progress! I hope you have a lot of fun with this, now that your motor is functioning properly.

My last words of wisdom... Always keep in mind that this is a hobby, and not a job or a demand upon you. You will enjoy it a lot more if you treat it as such. You'll keep your hair and your wife as well! Ha Ha!

RADAR

Radar I truly appreciate your ideas, time and encouragement!

Well after work today my neighbor and I spent about 90 mins working on things and are a bit frustrated at a couple of issues that have become evident.

Firstly, my once nicely vertical pole is now off by about 3 deg., we estimate. Caused most likely by the weight of the 48" dish/motor. As a result my neighbor dropped my motor elevation from 41 to about 36 deg. - his theory to compensate for the pole leaning slightly. He's got my dish set to about 27 deg. My concern is that i have heard that regardless of any adjustments made, if the pole isn't 100% straight, the set up will always be off. Does anyone have any viewpoints or anecdotal experiences to share.

Also, I bought a brand new powertech SG380 motor for up to a 1.2m dish from Sadoun and it does not appear to be functioning correctly. It won't move the dish to sats beyond 97w and makes a loud clicking and sometimes whining sound as if it's struggling to move the dish. It's response to my commands through the receiver are unreliable and erratic. These 2 issues are now preventing us from progressing with this project! I will call Sadoun tomorrow and perhaps try my old SG2100 smaller motor which always performed well in the past. And take a look at the pole while I have the motor off. Still going slow as far as fine tuning signals to best get the clark belt sats...

Well after work today my neighbor and I spent about 90 mins working on things and are a bit frustrated at a couple of issues that have become evident.

Firstly, my once nicely vertical pole is now off by about 3 deg., we estimate. Caused most likely by the weight of the 48" dish/motor. As a result my neighbor dropped my motor elevation from 41 to about 36 deg. - his theory to compensate for the pole leaning slightly. He's got my dish set to about 27 deg. My concern is that i have heard that regardless of any adjustments made, if the pole isn't 100% straight, the set up will always be off. Does anyone have any viewpoints or anecdotal experiences to share.

Also, I bought a brand new powertech SG380 motor for up to a 1.2m dish from Sadoun and it does not appear to be functioning correctly. It won't move the dish to sats beyond 97w and makes a loud clicking and sometimes whining sound as if it's struggling to move the dish. It's response to my commands through the receiver are unreliable and erratic. These 2 issues are now preventing us from progressing with this project! I will call Sadoun tomorrow and perhaps try my old SG2100 smaller motor which always performed well in the past. And take a look at the pole while I have the motor off. Still going slow as far as fine tuning signals to best get the clark belt sats...

- Status

- Please reply by conversation.

Similar threads

- Replies

- 4

- Views

- 868

- Replies

- 8

- Views

- 2K

- Replies

- 4

- Views

- 968

- Replies

- 4

- Views

- 1K