I know the actuator on this old dish can't be purchased new, I don't want to spend to much time looking for a original part, what are my options to modify a different actuator to fit securely? What parts would I need? Im hoping to get it up and running next month. I know I posted these photos in a general post earlier. I can probably figure the rest out as far as a new Receiver and running the wires.

Best option to replace/upgrade this actuator?

- Thread starter saboken

- Start date

- Latest activity Latest activity:

- Replies 18

- Views 3K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I was just looking on Amazon and found this one says 330lbs? It's almost identicalLikely the ONLY actuator strong enough to hold that dish, is a 36" Venture Ball-screw actuator. That would be around $400.

ECO-WORTHY Heavy Duty 330lbs Solar Tracker Linear Actuator Multi-function (12V, 12") Amazon product ASIN B00NM8H5SWView: https://www.amazon.com/dp/B00NM8H5SW/ref=cm_sw_r_apan_glt_fabc_K31DHM21KW40CDMJAV2B?_encoding=UTF8&psc=1

Nope, you specifically need an actuator meant for a satellite dish. That one is NOT. You can't skimp on this, BUT, you can try to find a good used one somewhere.I was just looking on Amazon and found this one says 330lbs? It's almost identical

ECO-WORTHY Heavy Duty 330lbs Solar Tracker Linear Actuator Multi-function (12V, 12") Amazon product ASIN B00NM8H5SWView: https://www.amazon.com/dp/B00NM8H5SW/ref=cm_sw_r_apan_glt_fabc_K31DHM21KW40CDMJAV2B?_encoding=UTF8&psc=1

Ok thanks it was to good to be true.Nope, you specifically need an actuator meant for a satellite dish. That one is NOT. You can't skimp on this, BUT, you can try to find a good used one somewhere.

What about this one?Ok thanks it was to good to be true.

C-Band Satellite Dish Actuator, Venture Maxi 810-24K Actuator Jack -

24", 32 Pulse, 1000 lb Load, Suggested mesh dish size is 10'

Like Mike said, for that big heavy dish you will need a 36 inch ball and screw. That actuator would be great for a 10 foot mesh, but not yours. Keep in mind you will need a powerfull dish mover to power it, a ball and srew will use less power than a acme nut, but with that much weight, I think your best bet would be a old analog box as a positioner.

Not sure I agree with the comments here that you need a 36 inch ball and screw. I used nothing but 24 inch Von Weise actuators for years on 10 foot fiberglass Prodelins without any problems. That was in Canadian winters with -35 C temperatures. The ball screw Thompson-Saginaws would freeze up without a heat tape.

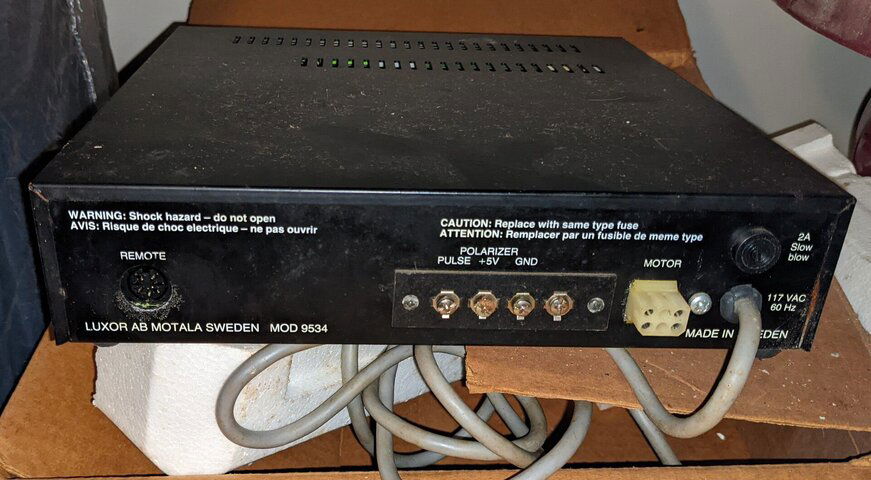

I have the old equipmentLike Mike said, for that big heavy dish you will need a 36 inch ball and screw. That actuator would be great for a 10 foot mesh, but not yours. Keep in mind you will need a powerfull dish mover to power it, a ball and srew will use less power than a acme nut, but with that much weight, I think your best bet would be a old analog box as a positioner.

Attachments

considering the cost of a new quality actuator, I would start by a close inspection of the one you have. I would try to repair that fixed steel bar that was made to replace it, so that you can take the actuator inside on a work bench, and open its cover. Take plenty of pictures before you take anything apart so that you know how to put it back together.I know the actuator on this old dish can't be purchased new, I don't want to spend to much time looking for a original part, what are my options to modify a different actuator to fit securely? What parts would I need? Im hoping to get it up and running next month. I know I posted these photos in a general post earlier. I can probably figure the rest out as far as a new Receiver and running the wires.

Maybe the thing is worn or broken beyond repair, but maybe not. In any case I think it's worth trying and always a good learning experience.

my guess is that the ACME nut is worn. On those actuators I think it's made of nylon. But even if there's some play it might be good enough to get you going until you find a replacement actuator.

one more thing... when you try to get this dish moving, avoid standing in its way. It is probably crazy heavy and you don't want it to hit you if something breaks (for example if the acme nut in the actuator breaks)

I think the acme nut on mine is steel but it's been a year since I've had it apart, and I've slept since then….. and 35 year old nylon doesn't do well here in the southwest lol when the ball joint on mine snapped I didn't have the dish on the mount luckily but I did have to jump back to keep the mount from smacking me. Of course we have so little rain here that mine was hardly rusty and just needed a little wd-40 and grease to get moving. My dish is aluminum and not that heavy though.

I'd pass on that one. I purchased it for a tractor modification project a few years back and it did not last. As they say - you get what you pay for.I was just looking on Amazon and found this one says 330lbs? It's almost identical

ECO-WORTHY Heavy Duty 330lbs Solar Tracker Linear Actuator Multi-function (12V, 12") Amazon product ASIN B00NM8H5SWView: https://www.amazon.com/dp/B00NM8H5SW/ref=cm_sw_r_apan_glt_fabc_K31DHM21KW40CDMJAV2B?_encoding=UTF8&psc=1

If I were you, I would spend some time looking for old dishes. I don't know where you live, but the areas just outside cities that had no cable are usually good places to look.I have the old equipment

Don't worry if the dish is wrecked when you are looking because you just want the actuator, feed horn, and LNB. You might have to haul away a damaged dish to get the parts that you want. If it is aluminum you can take it to the scrapyard.

The dish you have seems to be ok and just needs a little elbow grease and paint. The wiring is probably ok, but I would use a multi meter and check first before powering anything up.

Good Luck!

From your posts here saboken it looks like you need a plan. And a budget. Trying to macgyver or green acres your dish back to working with what's there could leave you a failed project.

Your actuator is crusty. Just unbolt the motor and see if you can at bare minimum turn the tube shaft at all.

I would ratchet strap the dish in that position and ditch the pipe that holds it in place.

The internal screw thread may or may not be toast. Test it.

In other words. See if it is capable of supporting the dish weight. And holding it in a stable position.

Next. Look. You're going to need a modern lnbf. I would bet you have a Chaparral Corotor under that nose cone. And birds nests mixed with hornets.

It's going to be crusty. Polarity mechanism will need to be gone over. Prime candidate for a new lnbf.

And a modern receiver. The guys can recommend a low priced one. But the osmio won't let you down.

This is all based on the cabling back to the house is still intact.

At the very least I would check every wire of every cable with a multimeter. Did you crack the junction box open?

You didn't state what your mechanical/electrical/electronics experience is. You're going to need it all.

Ummm....a pressure washer with bleach in the tank wouldn't hurt.

So. What's you game plan?

..Can the dish be held on one position with the existing actuator? Can it be manually moved? Grease the dish bearings.

..Is it worth it for you? Cabling in good shape? Do you know if you want c-band, ku band, or both?

..Next is to pair up an receiver/lnf. Worry about getting a signal with the setup before moving the dish. Of course manually operating the actuator will be needed. Many of us ran out in the snow back in the day to turn a crank and look at a protractor sticker.

..Then think about how you will move the dish. You'll have channels on a sat. Good and strong. Looks like you have a good horizon. Go for a 36" actuator. Just do it. And stay away from the superjack type brands.

I started out with a dish not-as-crusty as yours with bolt and bushing pivots. But pretty much everything you're looking at. It will probably be good to use for a long time seeing it was put up mid-80's.

Your actuator is crusty. Just unbolt the motor and see if you can at bare minimum turn the tube shaft at all.

I would ratchet strap the dish in that position and ditch the pipe that holds it in place.

The internal screw thread may or may not be toast. Test it.

In other words. See if it is capable of supporting the dish weight. And holding it in a stable position.

Next. Look. You're going to need a modern lnbf. I would bet you have a Chaparral Corotor under that nose cone. And birds nests mixed with hornets.

It's going to be crusty. Polarity mechanism will need to be gone over. Prime candidate for a new lnbf.

And a modern receiver. The guys can recommend a low priced one. But the osmio won't let you down.

This is all based on the cabling back to the house is still intact.

At the very least I would check every wire of every cable with a multimeter. Did you crack the junction box open?

You didn't state what your mechanical/electrical/electronics experience is. You're going to need it all.

Ummm....a pressure washer with bleach in the tank wouldn't hurt.

So. What's you game plan?

..Can the dish be held on one position with the existing actuator? Can it be manually moved? Grease the dish bearings.

..Is it worth it for you? Cabling in good shape? Do you know if you want c-band, ku band, or both?

..Next is to pair up an receiver/lnf. Worry about getting a signal with the setup before moving the dish. Of course manually operating the actuator will be needed. Many of us ran out in the snow back in the day to turn a crank and look at a protractor sticker.

..Then think about how you will move the dish. You'll have channels on a sat. Good and strong. Looks like you have a good horizon. Go for a 36" actuator. Just do it. And stay away from the superjack type brands.

I started out with a dish not-as-crusty as yours with bolt and bushing pivots. But pretty much everything you're looking at. It will probably be good to use for a long time seeing it was put up mid-80's.

Would it be easier to just replace it with a 10' it larger mesh dish and hardware? Can the mesh dish be easily mounted to the existing post?From your posts here saboken it looks like you need a plan. And a budget. Trying to macgyver or green acres your dish back to working with what's there could leave you a failed project.

Your actuator is crusty. Just unbolt the motor and see if you can at bare minimum turn the tube shaft at all.

I would ratchet strap the dish in that position and ditch the pipe that holds it in place.

The internal screw thread may or may not be toast. Test it.

In other words. See if it is capable of supporting the dish weight. And holding it in a stable position.

Next. Look. You're going to need a modern lnbf. I would bet you have a Chaparral Corotor under that nose cone. And birds nests mixed with hornets.

It's going to be crusty. Polarity mechanism will need to be gone over. Prime candidate for a new lnbf.

And a modern receiver. The guys can recommend a low priced one. But the osmio won't let you down.

This is all based on the cabling back to the house is still intact.

At the very least I would check every wire of every cable with a multimeter. Did you crack the junction box open?

You didn't state what your mechanical/electrical/electronics experience is. You're going to need it all.

Ummm....a pressure washer with bleach in the tank wouldn't hurt.

So. What's you game plan?

..Can the dish be held on one position with the existing actuator? Can it be manually moved? Grease the dish bearings.

..Is it worth it for you? Cabling in good shape? Do you know if you want c-band, ku band, or both?

..Next is to pair up an receiver/lnf. Worry about getting a signal with the setup before moving the dish. Of course manually operating the actuator will be needed. Many of us ran out in the snow back in the day to turn a crank and look at a protractor sticker.

..Then think about how you will move the dish. You'll have channels on a sat. Good and strong. Looks like you have a good horizon. Go for a 36" actuator. Just do it. And stay away from the superjack type brands.

I started out with a dish not-as-crusty as yours with bolt and bushing pivots. But pretty much everything you're looking at. It will probably be good to use for a long time seeing it was put up mid-80's.

Depends on pole size. A 10 footer generally fits on a 3.5 inch OD pole. You would need an adapter sleeve to mount a 12 footer on a 3.5 inch OD pole since they are usually designed for a 4.5 inch OD pole.Would it be easier to just replace it with a 10' it larger mesh dish and hardware? Can the mesh dish be easily mounted to the existing post?

I've been using 36 inch Venture actuators on my 12 footers (mesh). They seem to hold up well even though they're not the ball type. By the way, the actuator in your photos should be rotated 180 degrees so that the motor is above the tube so that it keeps water out of the motor.

I'm not recommending this particular actuator. It uses a reed switch and only 3 magnets on the main gear, so the count really isn't accurate enough for digital signals. There are also no hard limit switches. I might engineer a way to get more/accurate counts on mine, we'll see…….

Similar threads

- Replies

- 8

- Views

- 415

- Replies

- 4

- Views

- 1K

- Replies

- 0

- Views

- 578

- Replies

- 0

- Views

- 664

Users Who Are Viewing This Thread (Total: 0, Members: 0, Guests: 0)

Who Read This Thread (Total Members: 10)

Latest posts

-

-

-

-

TMicrosoft's Maia 200 AI Accelerator Chip is a Dramatic Upgrade #shorts

- Latest: TWiT Tech Podcast Network

-