I recently picked up my 12ft Paraclipse Dish and it came with what appears to be a Heavy Duty Actuator and has writings on it ("PERFORMANCE PAK" SAGINAW STEERING GEAR" "A DIVISION OF GENERAL MOTORS CORP") Well, in my excitement to test the actuator I ended up frying my Powertech GBox 3000. I tried a few combinations of the six wires found on the Actuator connected to the GBox 3000, and finally I got it working by connecting the thick gauged white and green wires to the GBox's "Motor+" "Motor-" and the thin black and gray wires on the "Sensor-" "Sensor+"terminals to get the Actuator to move up and down. My excitement was short lived as I noticed when i pressed down on the arrows to move left or right that the actuator only moved a little at a time and stopped. Also the GBox was indicating an error E----2. After a while of moving the actuator a little bit at a time, it suddenly began to extend continuously without control from the GBox only stopping when the power to the GBox is disconnected. It should be noted that the GBox moves the Actuator even when the unit is not switched on, but connected to power socket. A quick sniff at the back of the GBox smells of burnt electronic part. My fear now is I hope I have not destroyed the Actuator also.

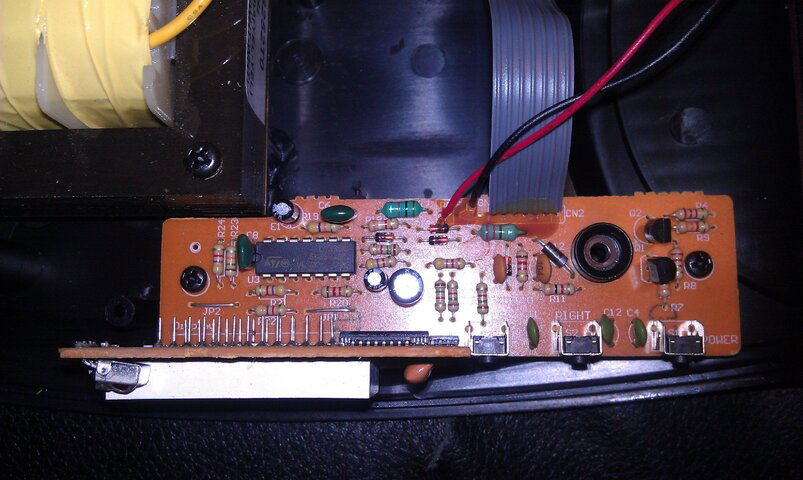

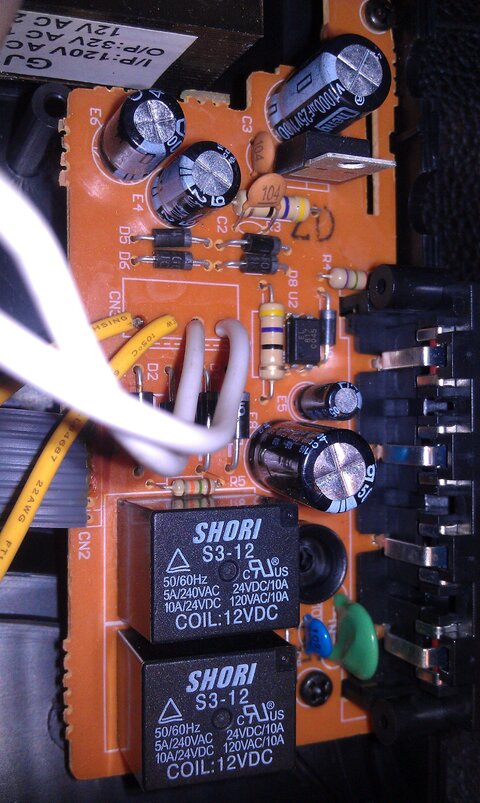

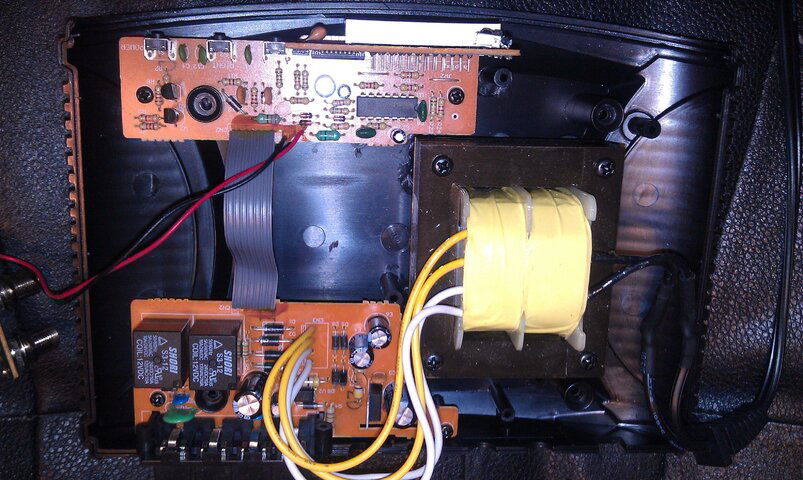

I need help identifying those 6 wires and if anyone has a manual of the actuator to please post it here. I also need help fixing my GBox 3000. I spoke to people at Sadoun and they said based on my description of what happened that identifying and replacing the burnt diode will fix the problem. Unfortunately, I'm not very knowledgeable with fixing electronic parts that small. Anyone capable of fixing the Gbox 3000 should please send me a PM.

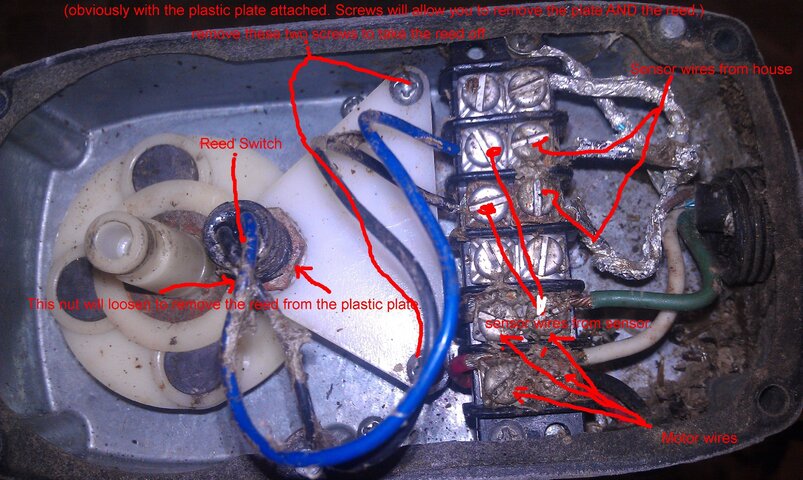

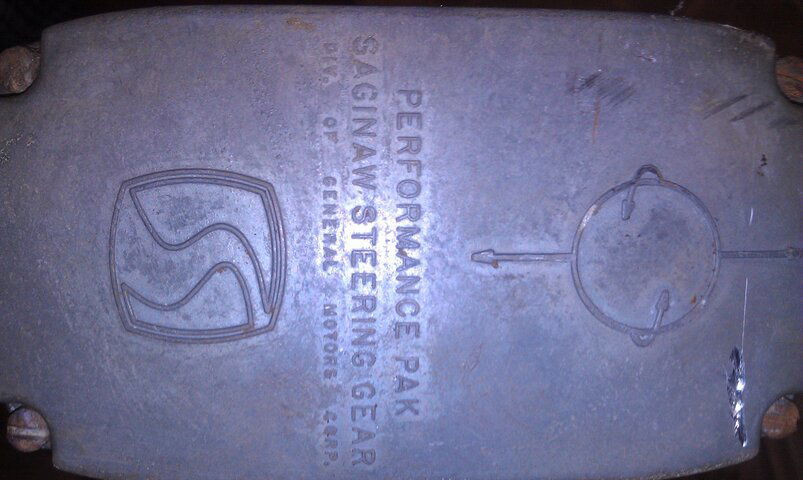

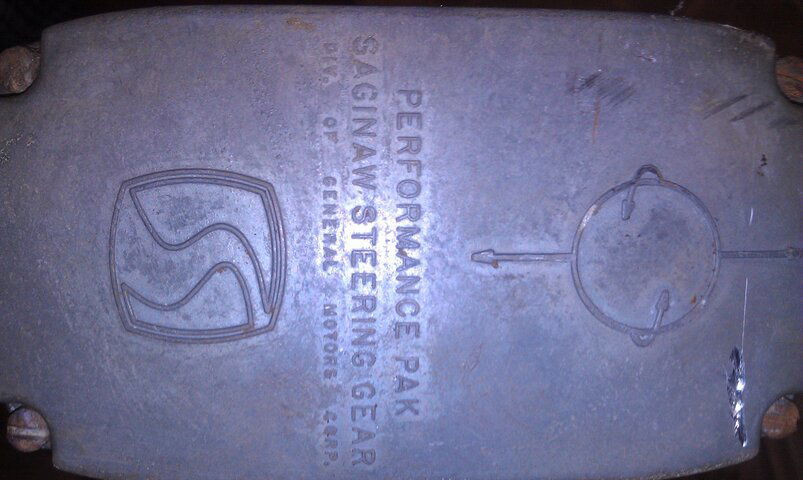

Below are pictures of the actuator and some markings found on it.

What agent or method can I use to clean off rust so that the ball joint on this actuator arm can move freely and smoothly, or where I can get a replacement part. See rusted ball joint below:

I need help identifying those 6 wires and if anyone has a manual of the actuator to please post it here. I also need help fixing my GBox 3000. I spoke to people at Sadoun and they said based on my description of what happened that identifying and replacing the burnt diode will fix the problem. Unfortunately, I'm not very knowledgeable with fixing electronic parts that small. Anyone capable of fixing the Gbox 3000 should please send me a PM.

Below are pictures of the actuator and some markings found on it.

What agent or method can I use to clean off rust so that the ball joint on this actuator arm can move freely and smoothly, or where I can get a replacement part. See rusted ball joint below: