I do a lot of high end installs and repair a lot of OLD ones, like yours andbring them to PREMIUM quality.

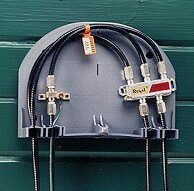

I have attached a photo of my owm personal install.

First, I can't figure, from your pictures, where the picture of the carpet covered vent is in relation to the location of the ground pole.

The cable does NOT appear to be of the type designated as DIRECT BURIAL.

I don't know why the original DirecTV installer made entry into the house at a direct shot to the area of the crawl space right below the power meter, installed the two dual grounding blocks there, and attached the ground to the service entrance ground. The grounding blocks, idealy, should be placed in a weatherproof box, like the one you see in my photo.

You can replace the grounding blocks at the pole with barrel connectors and place the connections inside of a weatherproof box. Use the compression connectors, and just replace the sections of coax from the connections to the lnb with longer ones. The metal pole can be grounded to the ground rod, but the ground rod should be driven so that it is completely buried.

My pole is made of 1-1/4 inch nominal schedule 40 aluminum pipe. It will NEVER rust. I've installed such poles that are nearly 10 years old. They look as good as mine. I've seen 40 year old aluminum conduits on buildings. They still look good and are just a little greyer.

If you can't find the boxes I mention, send me a PM. I can provide you with good ones, as well as an aluminum pole.

I have attached a photo of my owm personal install.

First, I can't figure, from your pictures, where the picture of the carpet covered vent is in relation to the location of the ground pole.

The cable does NOT appear to be of the type designated as DIRECT BURIAL.

I don't know why the original DirecTV installer made entry into the house at a direct shot to the area of the crawl space right below the power meter, installed the two dual grounding blocks there, and attached the ground to the service entrance ground. The grounding blocks, idealy, should be placed in a weatherproof box, like the one you see in my photo.

You can replace the grounding blocks at the pole with barrel connectors and place the connections inside of a weatherproof box. Use the compression connectors, and just replace the sections of coax from the connections to the lnb with longer ones. The metal pole can be grounded to the ground rod, but the ground rod should be driven so that it is completely buried.

My pole is made of 1-1/4 inch nominal schedule 40 aluminum pipe. It will NEVER rust. I've installed such poles that are nearly 10 years old. They look as good as mine. I've seen 40 year old aluminum conduits on buildings. They still look good and are just a little greyer.

If you can't find the boxes I mention, send me a PM. I can provide you with good ones, as well as an aluminum pole.