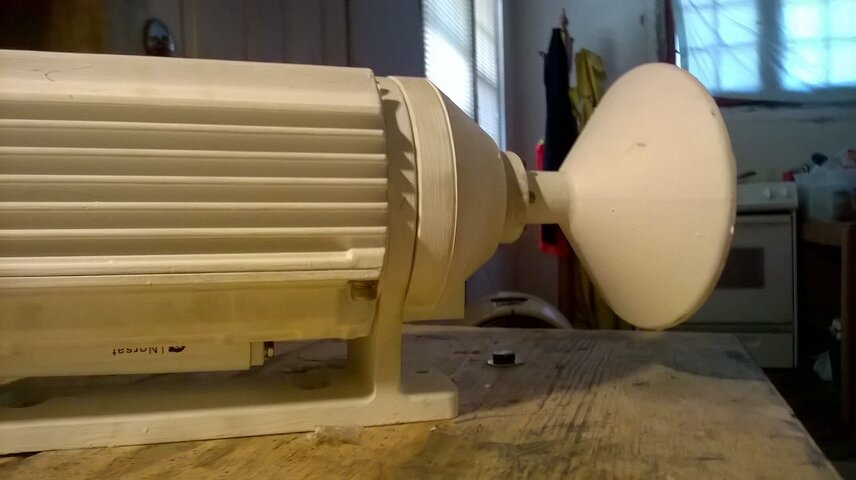

Hi folks  . I rescued a Prodelin dish from the garbage a little while ago. In those pics the dish doesn't look so bad. However the feedhorn support arms were severely rusted & the dish has a severe case of mold growing on it.

. I rescued a Prodelin dish from the garbage a little while ago. In those pics the dish doesn't look so bad. However the feedhorn support arms were severely rusted & the dish has a severe case of mold growing on it.

So I cleaned the dish & arms with a soapy water/bleach solution using a scouring pad. The results are good now. I am going to paint the arms & dish mount with cold galvaninizing compound aerosol spray paint http://www.rustoleum.com/product-ca...2100-system-galvanizing-compound-spray-paint/ I've semi completed the conversion from a fixed az/el mount to a polar mount. Credit for this design goes to members here ------ pendragon,stogie5150. here's stogies 1.8m dish modifications.

So I cleaned the dish & arms with a soapy water/bleach solution using a scouring pad. The results are good now. I am going to paint the arms & dish mount with cold galvaninizing compound aerosol spray paint http://www.rustoleum.com/product-ca...2100-system-galvanizing-compound-spray-paint/ I've semi completed the conversion from a fixed az/el mount to a polar mount. Credit for this design goes to members here ------ pendragon,stogie5150. here's stogies 1.8m dish modifications.

So I'm going to copy most of that but put the threaded rods further apart and larger angle iron for more stability.

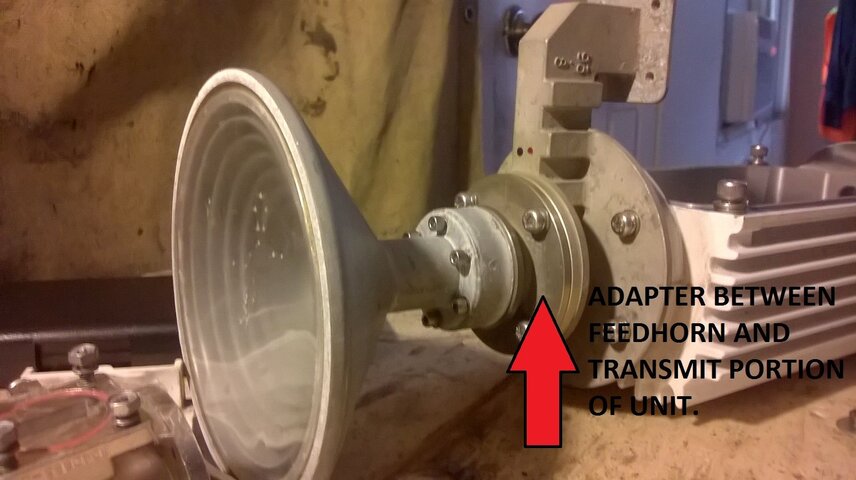

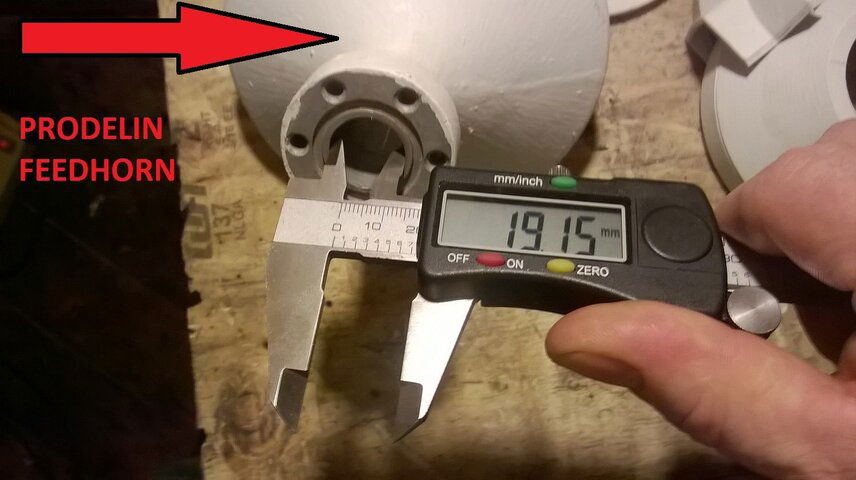

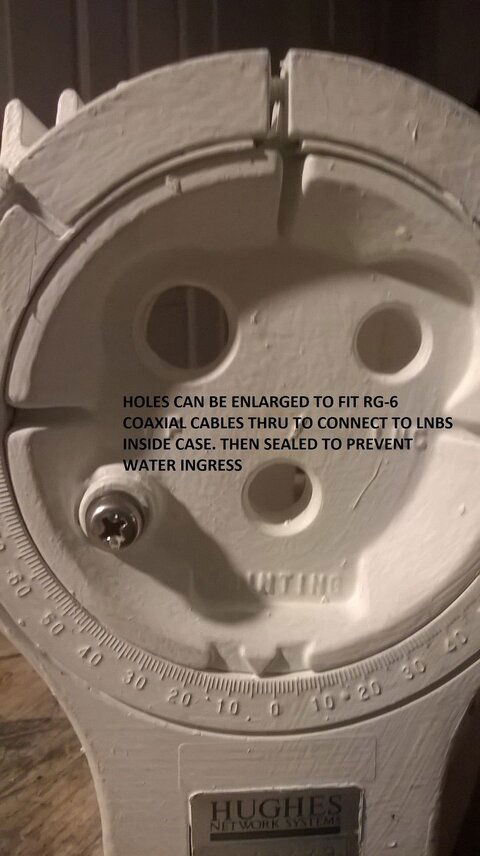

So I'm going to copy most of that but put the threaded rods further apart and larger angle iron for more stability.  Another part of the process is what to use for the feedhorn & lnb. These were transmit & receive setups originally but us FTA hobbyists can only legally receive signals not transmit. So I wanted to use the original feedhorn. more to come

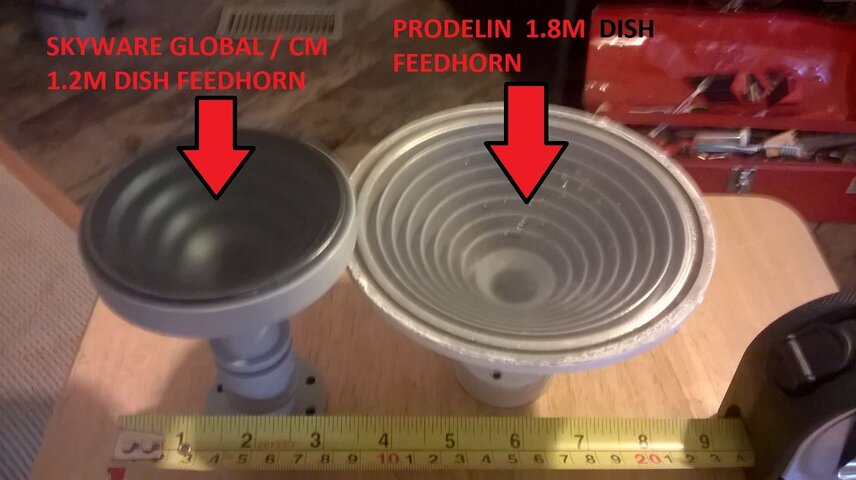

Another part of the process is what to use for the feedhorn & lnb. These were transmit & receive setups originally but us FTA hobbyists can only legally receive signals not transmit. So I wanted to use the original feedhorn. more to come

So I cleaned the dish & arms with a soapy water/bleach solution using a scouring pad. The results are good now. I am going to paint the arms & dish mount with cold galvaninizing compound aerosol spray paint http://www.rustoleum.com/product-ca...2100-system-galvanizing-compound-spray-paint/ I've semi completed the conversion from a fixed az/el mount to a polar mount. Credit for this design goes to members here ------ pendragon,stogie5150. here's stogies 1.8m dish modifications.

So I cleaned the dish & arms with a soapy water/bleach solution using a scouring pad. The results are good now. I am going to paint the arms & dish mount with cold galvaninizing compound aerosol spray paint http://www.rustoleum.com/product-ca...2100-system-galvanizing-compound-spray-paint/ I've semi completed the conversion from a fixed az/el mount to a polar mount. Credit for this design goes to members here ------ pendragon,stogie5150. here's stogies 1.8m dish modifications.

So I'm going to copy most of that but put the threaded rods further apart and larger angle iron for more stability.

So I'm going to copy most of that but put the threaded rods further apart and larger angle iron for more stability.  Another part of the process is what to use for the feedhorn & lnb. These were transmit & receive setups originally but us FTA hobbyists can only legally receive signals not transmit. So I wanted to use the original feedhorn. more to come

Another part of the process is what to use for the feedhorn & lnb. These were transmit & receive setups originally but us FTA hobbyists can only legally receive signals not transmit. So I wanted to use the original feedhorn. more to come

Last edited:

![WP_20150808_001[1].jpg WP_20150808_001[1].jpg](https://cdn.satelliteguys.us/xen/data/attachments/89/89881-7350cc13c5c413267118619a51be51ec.jpg?hash=c1DME8XEEy)

![WP_20150808_002[1].jpg WP_20150808_002[1].jpg](https://cdn.satelliteguys.us/xen/data/attachments/89/89882-e776ccb334a3b4ca2ff3722f0e54656c.jpg?hash=53bMszSjtM)

![WP_20150808_003[1].jpg WP_20150808_003[1].jpg](https://cdn.satelliteguys.us/xen/data/attachments/89/89890-fa53a25dbd4ba729c3a6886406411a1b.jpg?hash=-lOiXb1Lpy)

![WP_20150808_002[1].jpg WP_20150808_002[1].jpg](https://cdn.satelliteguys.us/xen/data/attachments/89/89920-e776ccb334a3b4ca2ff3722f0e54656c.jpg?hash=53bMszSjtM)

![WP_20150809_008[1].jpg WP_20150809_008[1].jpg](https://cdn.satelliteguys.us/xen/data/attachments/89/89921-da9299b2588dc2e9179e83c66882bfe3.jpg?hash=2pKZsliNwu)

![WP_20150809_005[1].jpg WP_20150809_005[1].jpg](https://cdn.satelliteguys.us/xen/data/attachments/89/89923-6dc9acb07cd2edfa2e8d680af78a276b.jpg?hash=bcmssHzS7f)