Help to ID this BUD Manufacturer and f/d ratio

- Thread starter Vintagesports

- Start date

- Latest activity Latest activity:

- Replies 120

- Views 10K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Please reply by conversation.

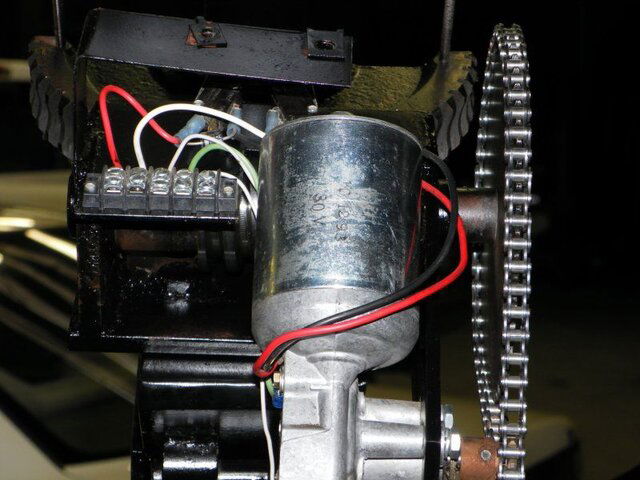

The weight will be not enough , I suggest after long time soaking put the parts together as on this picture except the worm gear .

If its steady on the pole You can try to turn the axel with your hands at the wide ring .

Once its moving , remove the lower turning bolt and loosen the the top nuts so You can move the wide ring a bit aside .

Than try to pull and twist the axel out .

Since there is a nylon bushing in it I would not heaten it with a flame burner .

If its steady on the pole You can try to turn the axel with your hands at the wide ring .

Once its moving , remove the lower turning bolt and loosen the the top nuts so You can move the wide ring a bit aside .

Than try to pull and twist the axel out .

Since there is a nylon bushing in it I would not heaten it with a flame burner .

Attachments

The weight will be not enough , I suggest after long time soaking put the parts together as on this picture except the worm gear .

If its steady on the pole You can try to turn the axel with your hands at the wide ring .

Once its moving , remove the lower turning bolt and loosen the the top nuts so You can move the wide ring a bit aside .

Than try to pull and twist the axel out .

Since there is a nylon bushing in it I would not heaten it with a flame burner .

Sounds like your recommendation might work! Thank you Trust will post results in a couple of days. Will keep soaking it for awhile.

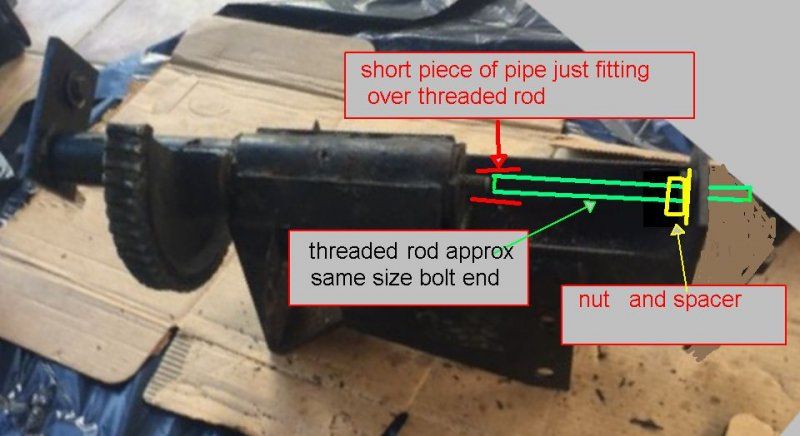

To keep pressure to put out the axle You can use a piece of threaded rod about the same diameter .

Turning the nut will put pressure on the axle .

Turning the nut will put pressure on the axle .

This is on top of your first reccommendation Trust?

Or a different one? Here I need to be careful not to damage the thread

Or a different one? Here I need to be careful not to damage the thread

PLEASE LOG IN TO GET RID OF THESE ADS!

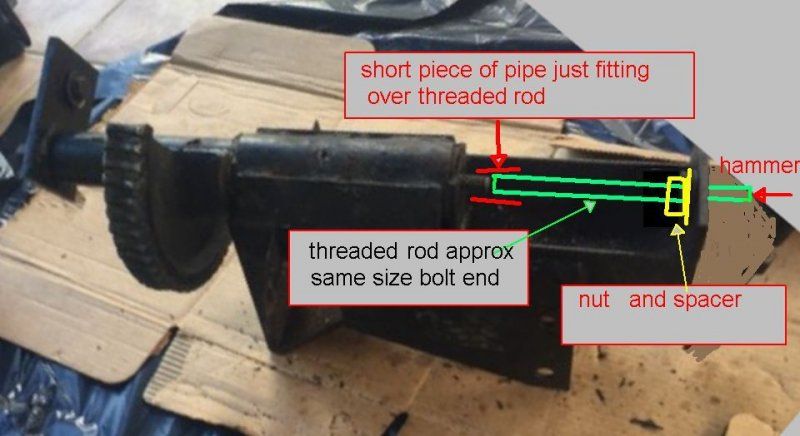

You can try it after soaking , put up the tension and use the hammer .

If no result , try my first idea and when the axle moves , than use that threaded rod to bring some tension .

Its easier to lift the axle by that rod instead of keep lifting that heavy part and turn it at the same time .

To push out the axle , the rod has to be pulling out long enough , not as short on the picture .

If no result , try my first idea and when the axle moves , than use that threaded rod to bring some tension .

Its easier to lift the axle by that rod instead of keep lifting that heavy part and turn it at the same time .

To push out the axle , the rod has to be pulling out long enough , not as short on the picture .

You can try it after soaking , put up the tension and use the hammer .

If no result , try my first idea and when the axle moves , than use that threaded rod to bring some tension .

Its easier to lift the axle by that rod instead of keep lifting that heavy part and turn it at the same time .

To push out the axle , the rod has to be pulling out long enough , not as short on the picture .

View attachment 130055

Thank you Trust. Been at it for days and haven't made progress hopefully will be able to pull this out with all your tips. Great forum and very helpful people here

I would not hammer against that bolt. The threaded part sticking out of the main shaft is a bolt welded into a thin piece covering the end of the tube which is that main shaft. I don't think that assembly can take that hammering. Some pictures from my first one.

View attachment 130056 View attachment 130057 View attachment 130058 View attachment 130059 View attachment 130060 View attachment 130061

Thanks Magic Static. Yes I am treating that end bolt like a baby! Taking this shaft out is more difficult them I thought. Must be really stuck! Hope I don't damage anything

Do you have a trumpet ?Got me this in Amazon maybe could help

Last edited:

View attachment 130105

Do you have a trumpet ?

Ja no trumpet

I thought it would be good to use it to pull the half moon shaft out. Did not read the spec. Wasted money I guess. Anyone need a trumpet puller?

I thought it would be good to use it to pull the half moon shaft out. Did not read the spec. Wasted money I guess. Anyone need a trumpet puller?

I just broke a tooth of the half moon gear. Would it still work without a teeth? Or should I throw it away and get done with it??

PLEASE LOG IN TO GET RID OF THESE ADS!

Weld a heavy bead across the broken area of the tooth and shape it with a grinder. And file it smooth. Just like new

I did that once with a big aluminium gear on a winch that was missing a tooth. The guy couldn't tell which tooth was replaced.

I did that once with a big aluminium gear on a winch that was missing a tooth. The guy couldn't tell which tooth was replaced.

PLEASE LOG IN TO GET RID OF THESE ADS!

- Status

- Please reply by conversation.

Similar threads

- Replies

- 5

- Views

- 1K

- Replies

- 1

- Views

- 823

- Replies

- 8

- Views

- 569

- Replies

- 17

- Views

- 3K

- Replies

- 1

- Views

- 546

Users Who Are Viewing This Thread (Total: 0, Members: 0, Guests: 0)

Who Read This Thread (Total Members: 3)

Latest posts

-

TWho Really Owns the Moon? Untangling Space Law Drama #shorts

- Latest: TWiT Tech Podcast Network

-

B

-

-