Basically trying to pick some experienced brains.

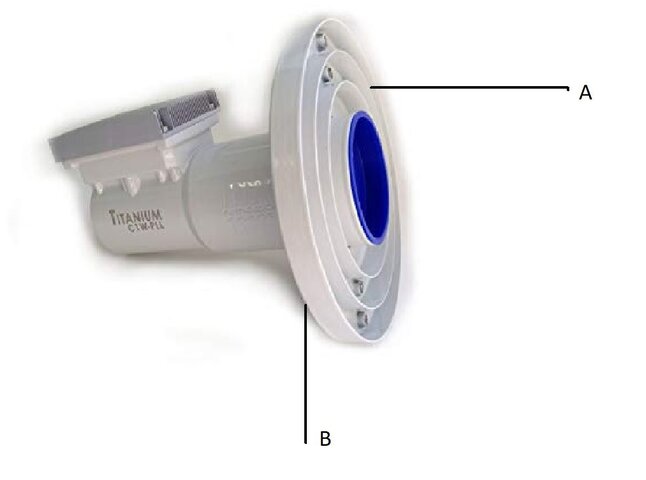

I have a button hook feed on a 12 foot dish for c band. It has the original Chaparral scalar and a C2W LNBF.

From reading here there seems to be a measure/ calculate f/d / position the scalar.

Not much on really tweaking the position of it. Kind of a George Foreman Grill thing. You know.

Guys. What to look for in peaking for maximum signals? If the scalar is too far in or out from the dish center?

One school of thought says the scalar acts like the secondary mirror of a Cassegrain telescope. It catches the signal from the rim of the dish, reflects it back towards the center, then blows it back to the feed throat.

Or it simply keeps the feed from "seeing" over the rim of the dish where interference may be picked up.

I'm trying to mentally understand the relation between scalar too far in and lnb positioned for maximum s/q and to far out with feed tweaked for max s/q. And where to find that happy place where it all peaks great.

My dish acts like it's sensitive to footprint. Like on 131W I have channels on certain tp's that are strong and others need a "bump" of the positioner a few clicks to peak signal. Hence the positioner memory slot 131W and 131W Bump.

Make sense?

I have a button hook feed on a 12 foot dish for c band. It has the original Chaparral scalar and a C2W LNBF.

From reading here there seems to be a measure/ calculate f/d / position the scalar.

Not much on really tweaking the position of it. Kind of a George Foreman Grill thing. You know.

Guys. What to look for in peaking for maximum signals? If the scalar is too far in or out from the dish center?

One school of thought says the scalar acts like the secondary mirror of a Cassegrain telescope. It catches the signal from the rim of the dish, reflects it back towards the center, then blows it back to the feed throat.

Or it simply keeps the feed from "seeing" over the rim of the dish where interference may be picked up.

I'm trying to mentally understand the relation between scalar too far in and lnb positioned for maximum s/q and to far out with feed tweaked for max s/q. And where to find that happy place where it all peaks great.

My dish acts like it's sensitive to footprint. Like on 131W I have channels on certain tp's that are strong and others need a "bump" of the positioner a few clicks to peak signal. Hence the positioner memory slot 131W and 131W Bump.

Make sense?