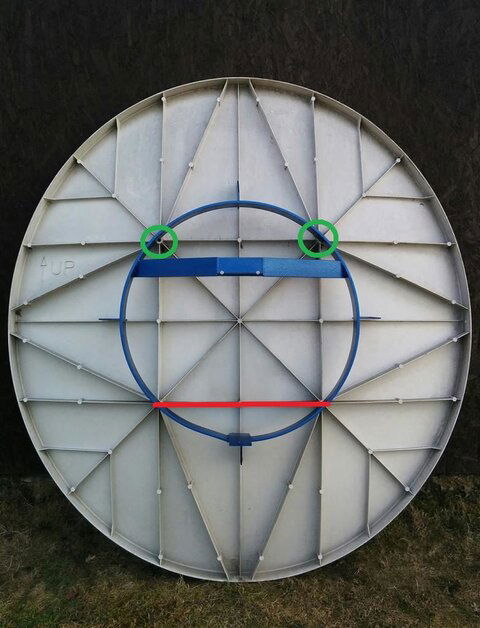

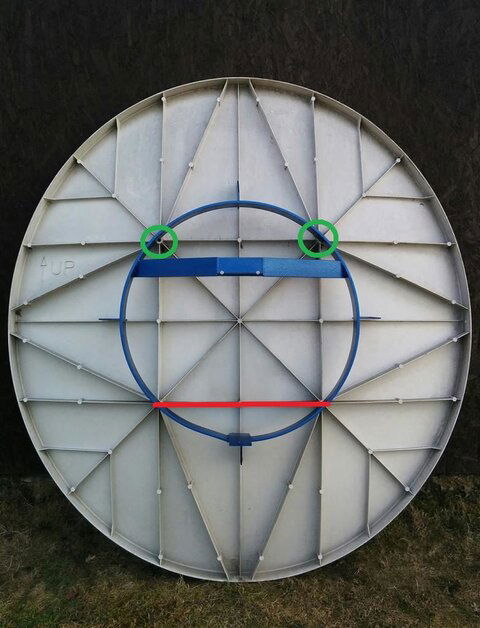

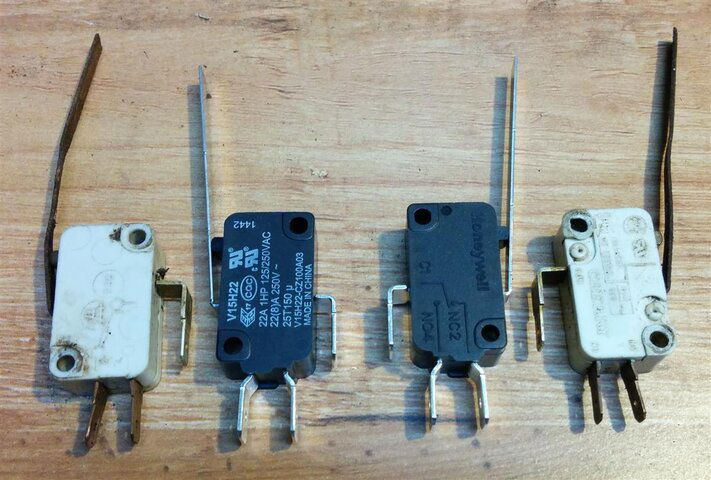

I've started some works on my Ajak. Of course, took it apart, cleaned, sanblasted, painted. Still need to find new end-switches, make Elevation and Declination adjusters. I like this motor!  It has task, for the beginning, to turn 1,8m Channel Master dish. Will think about improving of pulse-count afterwards.

It has task, for the beginning, to turn 1,8m Channel Master dish. Will think about improving of pulse-count afterwards.

You are an artist!

You are an artist!  , it is stuck and I am afraid to break it upon removal.

, it is stuck and I am afraid to break it upon removal.

. But what should I expect - Friday 13th!

. But what should I expect - Friday 13th!

that really hurts, even from here

that really hurts, even from here