The 7.5' mesh dish (several on this site helped me determine it is an Odom) I acquired awhile back is soon to placed back in operation at my place in TN. The dish came to me with a Superjack II+ which does not work so I am looking for a suitable new replacement actuator.

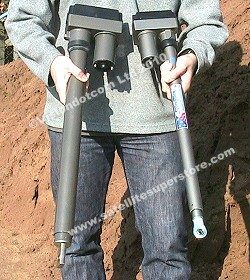

I do not know what size the Superjack is but I still have it. If someone could tell me where the lenght is measured that would help. Additionally my planes include purchasing a Gbox to drive this actuator so 36v is desired.

I should mention that I am on the lookout for a 10' dish eventually and want whatever I buy to cover this possibility. Also My LOS in TN is somewhat challenging and not likely to change. The dish will only see through 60 degrees max.

Looking over one of the Gold sponsors sites I see two 36v models to chose from. One a 18" and the other a 24". Which one is comparable to the broken Superjack? Or what would you recommend?

Thanks

I do not know what size the Superjack is but I still have it. If someone could tell me where the lenght is measured that would help. Additionally my planes include purchasing a Gbox to drive this actuator so 36v is desired.

I should mention that I am on the lookout for a 10' dish eventually and want whatever I buy to cover this possibility. Also My LOS in TN is somewhat challenging and not likely to change. The dish will only see through 60 degrees max.

Looking over one of the Gold sponsors sites I see two 36v models to chose from. One a 18" and the other a 24". Which one is comparable to the broken Superjack? Or what would you recommend?

Thanks