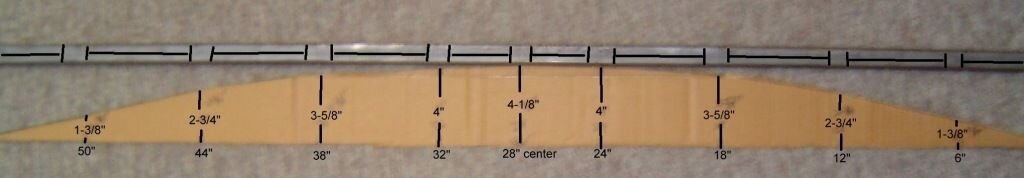

See drawing below.

Imagine standing above the dish and looking down.

Of the curves I have drawn, black being straight, dark blue, or light blue?

The light blue curve is what you want.

See drawing below.

Imagine standing above the dish and looking down.

Of the curves I have drawn, black being straight, dark blue, or light blue?

The light blue curve is what you want.

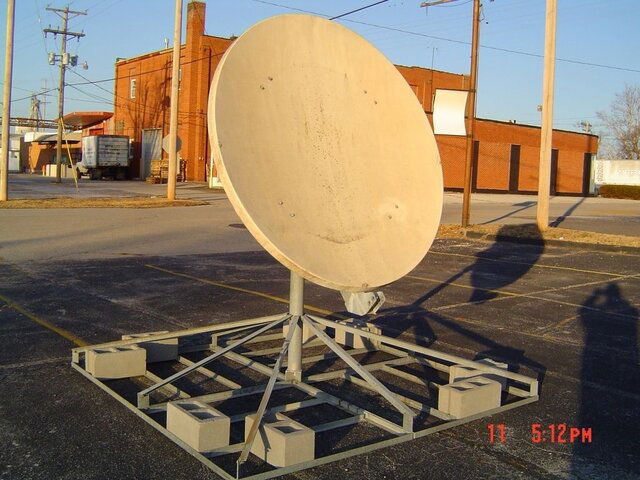

I vote for pointing it at 95, and see what kind of slice of the arc you get. For some reason I have a hard time seeing a 6' getting more than 6birds 2degrees apart, but then I never tried it either. Anole's math was impressive (I can barely understand a tire pressure guage lol) . Really curious to learn what the prodelin can do though, its a fine looking dish.

[FONT=Fixedsys]..

degree inch [/FONT][FONT=Fixedsys]for 6' Prodelin dish[/FONT]

[FONT=Fixedsys] orbital loc offset offset skew

74° H: +26.2° +22.95" -19.22[/FONT][FONT=Fixedsys]°[/FONT]

[FONT=Fixedsys] V: +3.0° +2.72"

79° H: +18.8° +16.75" -13.64[/FONT][FONT=Fixedsys]° [/FONT]

[FONT=Fixedsys] V: +1.4° +1.27"

83° H: +12.7° +11.4" -8.89[/FONT][FONT=Fixedsys]°[/FONT]

[FONT=Fixedsys] V: +0.6° +0.54

91° H: 0.0° 0.0" bore sight

V: 0.0° 0.0"

101° H: -15.8° -14.15" +13.21[/FONT][FONT=Fixedsys]°[/FONT]

[FONT=Fixedsys] V: +1.4° +1.27"

105° H: -21.7° -19.22" +17.74[/FONT][FONT=Fixedsys]°[/FONT]

[FONT=Fixedsys] V: +2.5° +2.26"

[COLOR=Blue]107.3[/COLOR]° H: -25.0° -21.97" +[COLOR=Blue]20.21[/COLOR][/FONT][FONT=Fixedsys]°[/FONT]

[FONT=Fixedsys] V: +3.4° +3.08"

...

[/FONT]

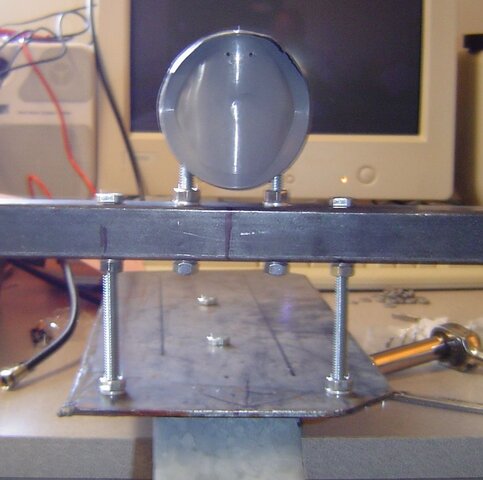

Me, hung up? :yikes:If you are hung up on using that elevation gauge, you'd better calibrate it.

Maybe it's right, and maybe it's wrong, and maybe your dis-assembly of the LNB arm left you off a few degrees.

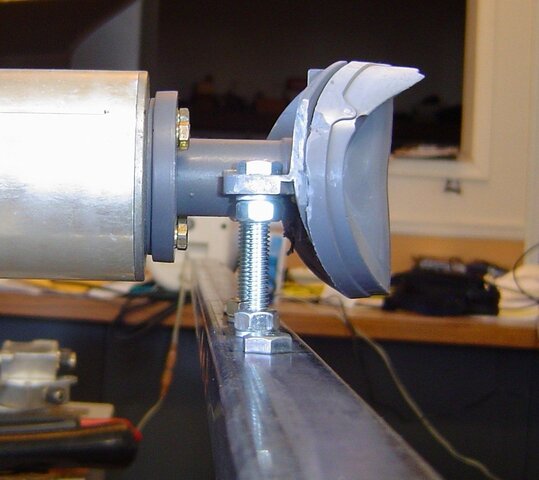

I went out and measured the bottom side of the dog leg, and it shows 45.1 degrees.I'd point you to a post I made a while back, about finding the focal point of a dish, given the mount was accurately calibrated.

But here, the question is about the calibration. . .

I'll take a look for some documents.

The mfgr's web site is full of PDFs... (see below*)

Should give the dish's offset angle, and a place to measure from, if not off a line across the face of the dish.

I believe you can put an angle finder on the lower LNB support in that short dog-leg at the bottom.

That should be the actual elevation angle of the dish.

But, that's from memory.

Let me mark-up a picture . . .

edit: added reference picture

And I would put the TS LNB at the 5 3/8th inch height.

* FindMeProdelin_1.8mDish.txt

1.2 1.8 meter dish / mesh ku offset ka rx/tx Andrew Channel Master Prodelin Solid 1 meter

http://www.gdsatcom.com/prodelin.html

My plan is to put in a 6" slot - 1/4" solid, another slot - solid, repeat to the ends of the rods.

How far out from center should I attempt my first slight bend?

What do you think so far?

[FONT=Fixedsys]..

degree inch [/FONT][FONT=Fixedsys]for 6' Prodelin dish[/FONT]

[FONT=Fixedsys] orbital loc offset offset skew

72° H: +29.0° +25.21" -21.33[/FONT][FONT=Fixedsys]°[/FONT]

[FONT=Fixedsys] V: +3.8° +3.44"

'"[/FONT]

Thanks for your kind words.i marvel at the creativity...of course i think i might like to follow your idea, so i watch anxiously at each development. could you toss that c band lnbf w feed horn at the center to add some bud spice to the ku krazyness? kudos to the effort, and the comments of the board- especially the bend of the bar to fit focal length. wow!

:

: