I've read about 'em, and am currently shopping for a Birdview.

Through many posts on them, I see that some parts may need replacing or remanufacturing.

I've got a buddy with mill and lathe in his garage, and if I needed a new part, I'd have him build it.

Seeing my friends suffer for lack of specialty parts is annoying, and if I can help, I will.

Bronze Bushing:

So far, we've looked at the main bronze bushing.

Without having one here to see, I've had the good fortune to find a photo with dimensions, and run that by my machinist.

It'd be easy to build, and I considered making up half-dozen of them.

But, with the post showing the somewhat similar part from McMaster-Carr, I felt users had a possible source.

That part -might- work, and all it needed was to be cut to length.

Haven't closed the books on that bushing, if someone wants to have more discussion.

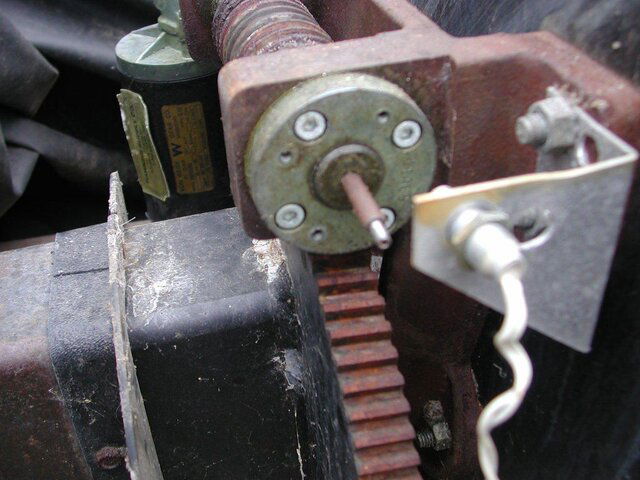

Magnet Wheel:

This is another part I would need, so it makes sense to build up a hand full for other users.

The original kit seems to no longer be available.

Much experimenting has been done here on the forum, so we have plenty of information to make a satisfactory wheel and reed kit.

I'm reluctant to make a disc that fits between the motor gearbox and worm gear.

To do so, the coupling needs to be removed by having a pin driven out.

So, my preference is to mount the new wheel at the far end of the worm, where the original gears and potentiometer was located.

To that end, I'm waiting on Phlatwound to post some pictures of the area, and maybe his original 8-magnet wheel.

If the free end of the worm proves too much trouble, then of course the fall-back position would be between motor gearbox and worm.

So, for now, I'm just waiting for pictures, and of course, more discussion is invited.

And if anyone has a source for the 24-magnet wheel that was used in the commercial kits, please let us know.

Through many posts on them, I see that some parts may need replacing or remanufacturing.

I've got a buddy with mill and lathe in his garage, and if I needed a new part, I'd have him build it.

Seeing my friends suffer for lack of specialty parts is annoying, and if I can help, I will.

Bronze Bushing:

So far, we've looked at the main bronze bushing.

Without having one here to see, I've had the good fortune to find a photo with dimensions, and run that by my machinist.

It'd be easy to build, and I considered making up half-dozen of them.

But, with the post showing the somewhat similar part from McMaster-Carr, I felt users had a possible source.

That part -might- work, and all it needed was to be cut to length.

Haven't closed the books on that bushing, if someone wants to have more discussion.

Magnet Wheel:

This is another part I would need, so it makes sense to build up a hand full for other users.

The original kit seems to no longer be available.

Much experimenting has been done here on the forum, so we have plenty of information to make a satisfactory wheel and reed kit.

I'm reluctant to make a disc that fits between the motor gearbox and worm gear.

To do so, the coupling needs to be removed by having a pin driven out.

So, my preference is to mount the new wheel at the far end of the worm, where the original gears and potentiometer was located.

To that end, I'm waiting on Phlatwound to post some pictures of the area, and maybe his original 8-magnet wheel.

If the free end of the worm proves too much trouble, then of course the fall-back position would be between motor gearbox and worm.

So, for now, I'm just waiting for pictures, and of course, more discussion is invited.

And if anyone has a source for the 24-magnet wheel that was used in the commercial kits, please let us know.