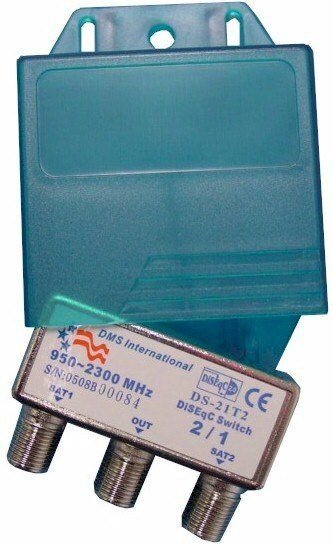

I came home today to no signal.. (at all) Turns out my DiSEqC switch died. all 4 ports, dead to the world. The back of the case was slightly dented, letting moisture inside and corroding all the internal stuff.

The dent pulled the seal away slightly so the water could get in. The switch is in the dark, so it never got any sun to cook the water back out.

The dent pulled the seal away slightly so the water could get in. The switch is in the dark, so it never got any sun to cook the water back out.