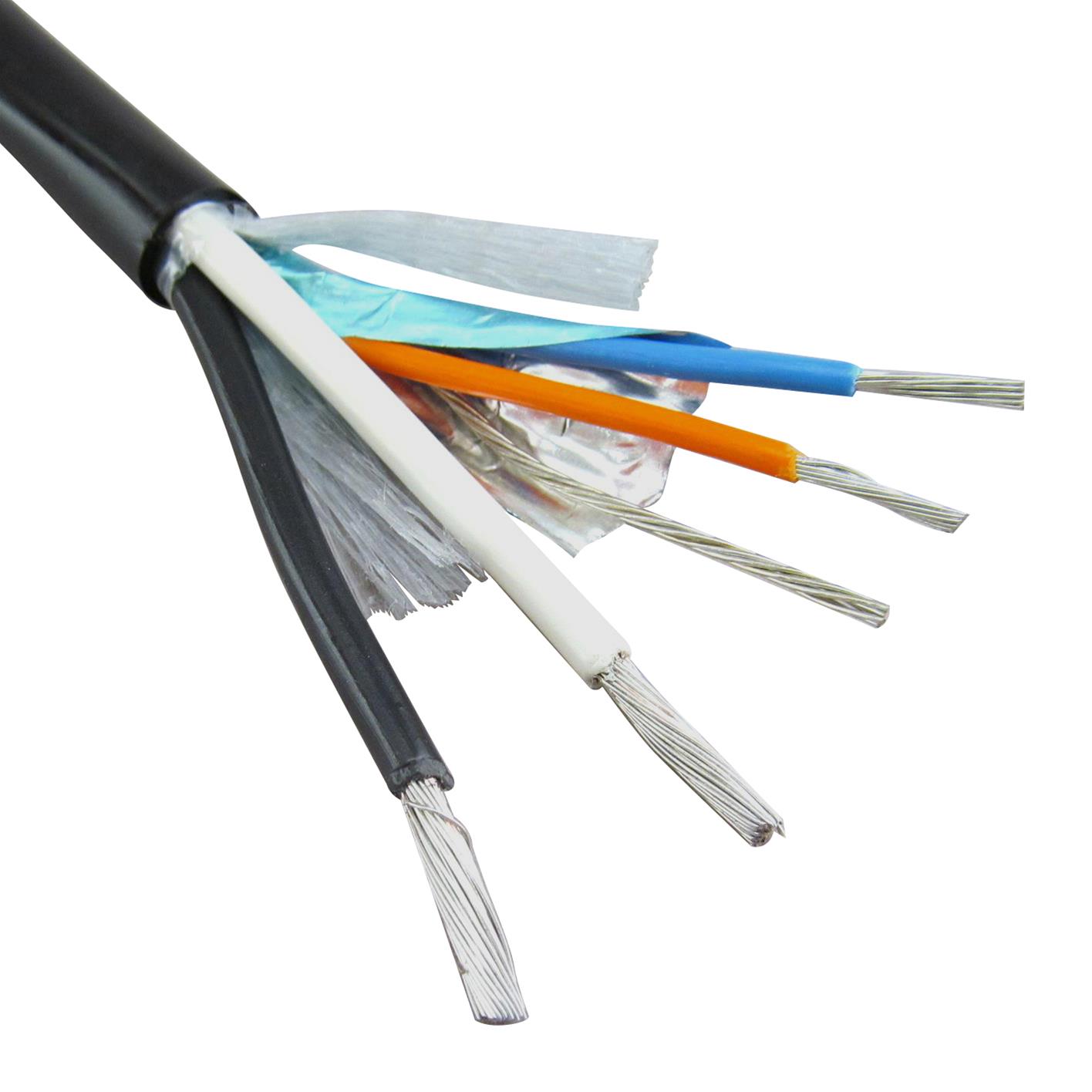

As we know ribbon cable is no longer sold and the existing stock is probably 15 + years old. I'm having a difficulty to figure which kinds of cables I will need and how many.

Wiring for the actuator and polarizer and servo and sensor etc. How many cables what kind and where to buy? Home Depot ? Also wanting to know what kind of tools do I need to put the screw ons on the end of the coaxial cables ?

Not putting up my system till I move to rural Ontario but doing install at my friends place and he's good with poles and tools so he's doing that part and I got him a 8 foot dish and echostar receiver ird and he ordered a gt box as well and I have to find him a view diseq switches. As the gt media has only one input so gotta put c and ku signal together. He's gutted whole house and wants to wire everything in because he's redoing the whole house and backyard so he's gonna run wiring and we are going to try pointing the dish and if we fail we will ask a member to come help us. Hope this will be a good learning experience and I can know more when I install my own 10 foot wineguard.

Wiring for the actuator and polarizer and servo and sensor etc. How many cables what kind and where to buy? Home Depot ? Also wanting to know what kind of tools do I need to put the screw ons on the end of the coaxial cables ?

Not putting up my system till I move to rural Ontario but doing install at my friends place and he's good with poles and tools so he's doing that part and I got him a 8 foot dish and echostar receiver ird and he ordered a gt box as well and I have to find him a view diseq switches. As the gt media has only one input so gotta put c and ku signal together. He's gutted whole house and wants to wire everything in because he's redoing the whole house and backyard so he's gonna run wiring and we are going to try pointing the dish and if we fail we will ask a member to come help us. Hope this will be a good learning experience and I can know more when I install my own 10 foot wineguard.