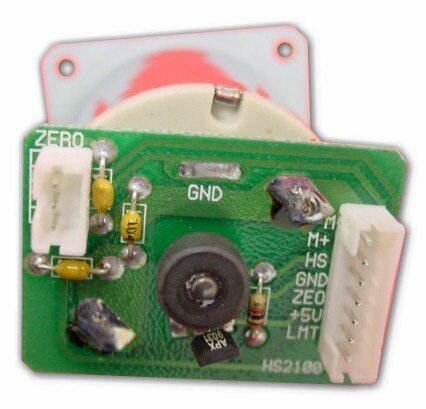

Within any satellite motor available (SG-2100, DG-240/280/380 or Stab motors) what kind of a motor is actually driving the gear train? Is it a simple DC motor or is it a stepper motor or something other?

If the motor has to count pulses to position properly I would assume it to be a stepper type motor, but it could also be using an electronic encoder as well or maybe both. A stepper or a servo motor or a brushless motor would make the most sense to me.

Can anyone inform me what is correct here?

Thanks

RADAR

If the motor has to count pulses to position properly I would assume it to be a stepper type motor, but it could also be using an electronic encoder as well or maybe both. A stepper or a servo motor or a brushless motor would make the most sense to me.

Can anyone inform me what is correct here?

Thanks

RADAR