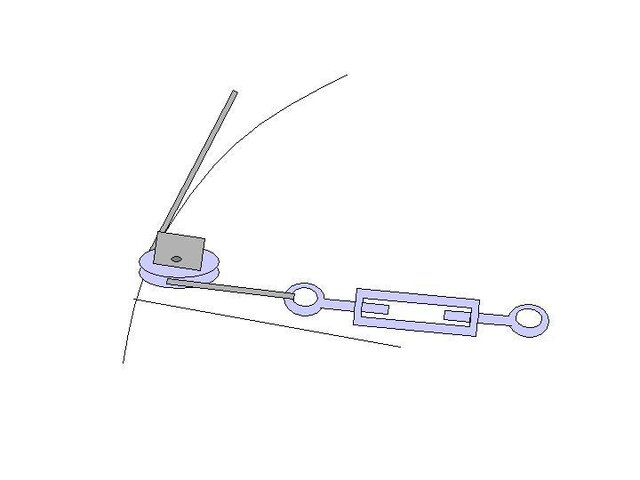

I just replaced my C-band feedhorn with a new Corotor II+, and Norsat LNBs for C/KU:

1) When I first hooked up the polarizer servo's wires, it started buzzing and wouldn't quit. I disconnected it and reconnected the old one and it didn't buzz, so was going to replace the new one with the old one, but when I unscrewed it, the buzzing stopped. I decided maybe it might settle down if I went in to the setup screens and tried to re-adjust it. That seemed to work. But I'm still not really sure what I did.

Question: Any idea what this was all about?

2) To my surprise, the standard Paraclipse feedhorn weather-shroud didn't quite fit the new feedhorn and LNBs and I had to cut a notch out of the bottom of it to clear the KU LNB. It was just about 1/2" too wide for the shroud. For now it is just cut out, but I will probably fabricate a fiberglass bulge addition to close it up once I get everything fully checked out. I did fully weatherproof all the connections with the parts you included and with some no-oxide sealer in the wire nuts for the servo.

Question: Is it possible to get one that might fit?

3) I don't have a lot of signal to spare on KU. I gather from what I have read that it is pretty demanding.

a) My DSR 922 says I have a signal of 100 and Quality=39 to 41 on TCM (X4-255), 100/49 on FMC (X4-251), and 100/51 on LMC (X4-253). Are those values reasonable? Or should I be able to do better?

b) Every time I switch to TCM (X4-255) it comes up with a lot of digital pixilated blocks and skipping audio. If I just key in the channel number several times, 255, 255, 255, etc., it will finally lock in. Other channels do not require this tweaking like TCM.

Question: Is this just characteristic of a marginal signal? It's not really an adjustment of the dish or skew, because I don't have to change them. It's almost like the frequency detector has to get centered a couple times to finally lock in. The picture looks perfect once it locks in.

4) I figured I would look at what I could do to tune up the dish.

a) The feedhorn is not quite centered on the dish (12' dish though, so maybe it is a bit forgiving). The shepherds-hook style center post is in good shape, but the guy wires were quite loose. I figured that in 15 or 20 years of being battered by our high winds, they've stretched a bit. I took a whack at tightening them and re-centering the horn, but I was running out of daylight and one of the screw adjusters was too rusted to budge. I would guess the feedhorn is probably now within about 1.5" of the center of the dish (as measured from horn center to dish rim), but I should be able to get it better than that.

b) The dish frame looks like it is quite straight, with no noticeable .

c) The mesh is an expanded metal mesh with about 0.16" (~5/32") openings, I assume that mesh is fine enough for KU?

d) The F/D spec for the dish is .375, so I adjusted the feedhorn ring just shy of the .38 markings, and got it as perpendicular as I could.

e) The coax is quite old (maybe 15 years or so), but I trimmed it back and re-terminated the KU end. The inner dielectric looked quite clean, and the center conductor was un-tarnished, so I think it is probably okay, but I don't have any test gear capable of testing it at the operating frequency.

f) I haven't tried re-aligning the dish azimuth or elevation adjustments; I'm a bit reluctant to mess with them unless I have to. It has been fine with C-band, but I realize that the KU alignment might be enough more critical to require some tweaking.

Question: Anything else I should do? How critically should I adjust the feedhorn centering? And should I try to tweak the dish mount?

It is great getting these extra channels, but I want to do whatever I can to make the signal more robust.

Any other thoughts?

1) When I first hooked up the polarizer servo's wires, it started buzzing and wouldn't quit. I disconnected it and reconnected the old one and it didn't buzz, so was going to replace the new one with the old one, but when I unscrewed it, the buzzing stopped. I decided maybe it might settle down if I went in to the setup screens and tried to re-adjust it. That seemed to work. But I'm still not really sure what I did.

Question: Any idea what this was all about?

2) To my surprise, the standard Paraclipse feedhorn weather-shroud didn't quite fit the new feedhorn and LNBs and I had to cut a notch out of the bottom of it to clear the KU LNB. It was just about 1/2" too wide for the shroud. For now it is just cut out, but I will probably fabricate a fiberglass bulge addition to close it up once I get everything fully checked out. I did fully weatherproof all the connections with the parts you included and with some no-oxide sealer in the wire nuts for the servo.

Question: Is it possible to get one that might fit?

3) I don't have a lot of signal to spare on KU. I gather from what I have read that it is pretty demanding.

a) My DSR 922 says I have a signal of 100 and Quality=39 to 41 on TCM (X4-255), 100/49 on FMC (X4-251), and 100/51 on LMC (X4-253). Are those values reasonable? Or should I be able to do better?

b) Every time I switch to TCM (X4-255) it comes up with a lot of digital pixilated blocks and skipping audio. If I just key in the channel number several times, 255, 255, 255, etc., it will finally lock in. Other channels do not require this tweaking like TCM.

Question: Is this just characteristic of a marginal signal? It's not really an adjustment of the dish or skew, because I don't have to change them. It's almost like the frequency detector has to get centered a couple times to finally lock in. The picture looks perfect once it locks in.

4) I figured I would look at what I could do to tune up the dish.

a) The feedhorn is not quite centered on the dish (12' dish though, so maybe it is a bit forgiving). The shepherds-hook style center post is in good shape, but the guy wires were quite loose. I figured that in 15 or 20 years of being battered by our high winds, they've stretched a bit. I took a whack at tightening them and re-centering the horn, but I was running out of daylight and one of the screw adjusters was too rusted to budge. I would guess the feedhorn is probably now within about 1.5" of the center of the dish (as measured from horn center to dish rim), but I should be able to get it better than that.

b) The dish frame looks like it is quite straight, with no noticeable .

c) The mesh is an expanded metal mesh with about 0.16" (~5/32") openings, I assume that mesh is fine enough for KU?

d) The F/D spec for the dish is .375, so I adjusted the feedhorn ring just shy of the .38 markings, and got it as perpendicular as I could.

e) The coax is quite old (maybe 15 years or so), but I trimmed it back and re-terminated the KU end. The inner dielectric looked quite clean, and the center conductor was un-tarnished, so I think it is probably okay, but I don't have any test gear capable of testing it at the operating frequency.

f) I haven't tried re-aligning the dish azimuth or elevation adjustments; I'm a bit reluctant to mess with them unless I have to. It has been fine with C-band, but I realize that the KU alignment might be enough more critical to require some tweaking.

Question: Anything else I should do? How critically should I adjust the feedhorn centering? And should I try to tweak the dish mount?

It is great getting these extra channels, but I want to do whatever I can to make the signal more robust.

Any other thoughts?