I dug out a heavier duty Von Weise actuator I had stored after my lighter duty Von Weise stripped the acme nut. I glued the magnets back in and put a lot of work in it. It seems the acme nut was about gone because I did clean and grease it good. I just set up a Freesat V7 and a V8 Super and that did it in.

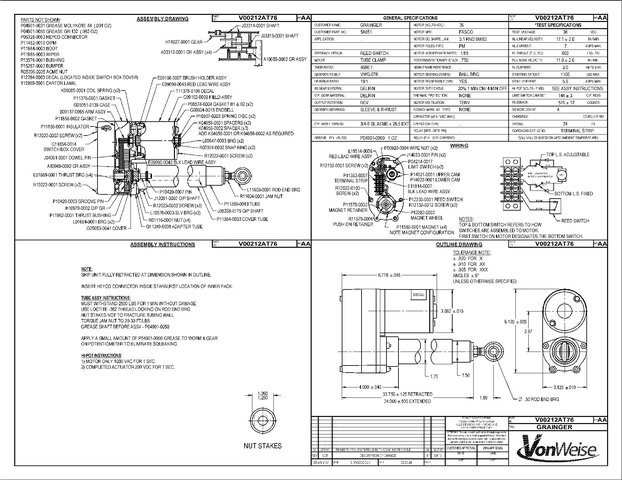

I've been over at Von Weise reading the descriptions of the actuators. The one for $199, the drawing says 33" retracted and 24" extended. That's not right! Then the $269 one says 33" retracted and 57" extended, that's right. Both are 24" stroke with reed switches.

I'd rather not spend $225 on a new one but I'm tired of messing with it and I can fix this one later. They have acme nuts for $20 but they want $20 to ship it and I can get a whole actuator shipped for $25, go figure.

I'm just tired of working on stuff!!!!! I had shoulder surgery and am behind on everything and it's been one thing after the other it seems. The car, the bedroom TV quit, actuator, lawn tractor, the Jeep and now the actuator again. I stayed up late to get the V8 Super programmed because I need to be doing other things, I'm sure you know how that goes.

I used Google cache to display this, otherwise you have to download it.

It lists a tube only which would get me going if it fits my motor but I expect it to cost too much, might as well get a new one. Do you guys know anything about it or the cost? #25 on the list.

25 6Z091 n/a V00212AK76 58.8 34.8 24 n/a n/a 14.0 lbs Tube

http://webcache.googleusercontent.c...ecrossreference.xls+&cd=2&hl=en&ct=clnk&gl=us

When I Google 6Z091 I get this which I assume is a photo of the tube only, but it could be for representation only and it's no longer available.

https://www.grainger.com/product/DAYTON-Tube-6Z091

Then they have this for $199, the one that's listed wrong in the drawing or I think it is, has to be.

DC Actuator 36 VDC, Full Load Speed 11 inches/minute, Gear Ration 19:1, Full Load Thurst 600 lbs, 1/15 HP, Current @ Full Load 3 Amps, Reed Switch. Substitute for Dayton 5A651.

http://estore.vonweise.com/vw7636vdcactuator-1.aspx

This one is $269.

Solar Panel/Satellite DC Actuator with Telescoping Tube Assembly. 24-36 VDC 1/15 HP Bidirectional Permanent Magnet Input Motor. 600 lbs. Full Load Thrust. Linear Velocity at Full Load Thrust 6.8 – 11.0 in/min. with 24 Inch Linear Stroke. Reed Switch Feedback Control. Limit Switches for overall stoke control. Enclosure Totally Enclosed Non-Ventilated. 19:1 Gearbox Ratio.

http://estore.vonweise.com/v76-5actuatorwithtelescopingtube.aspx

This one is $229 and not too clear on the details on length etc.

Solar Panel/Satellite DC Actuator with Telescoping Tube Assembly. 36 VDC 1/15 HP Bidirectional Permanent Magnet Input Motor. 300 lbs. Full Load Thrust. Linear Velocity at Full Load Thrust 11.0 in/min with 24 Inch Linear Stroke. Reed Switch Feedback Control. Limit Switches for Overall Stoke Control. Enclosure Totally Enclosed Non-Ventilated. 28:1 Gearbox Ratio

http://estore.vonweise.com/vw-24lcactuatorwithtelescopingtube.aspx

I've read a lot of bad, bad, things about the cheaper Super Jacks and the Maxi or whatever it's called, I forget. I've also read the thread on acme nut repair and I have a dremel but not a welder. I'd like to get it going cheap but I'll just buy a new one if I have to. I'm pooped and wanna watch TV, not work on it until Christmas.

I glued the magnets back in this motor and made a magnet wheel for it and converted it to a reed switch. It has been running great but I worry about the motor magnets, brushes etc and I want to be done with this. I hate to pay $20 for an acme nut and $20 to ship it (wow), then have the motor quit and end up buying a new one anyway, after installing a $40 acme nut in this one.

So, you are the guys to ask for certain, which of these is the right one or is that tube affordable?

I want my MTV (METV)!

I've been over at Von Weise reading the descriptions of the actuators. The one for $199, the drawing says 33" retracted and 24" extended. That's not right! Then the $269 one says 33" retracted and 57" extended, that's right. Both are 24" stroke with reed switches.

I'd rather not spend $225 on a new one but I'm tired of messing with it and I can fix this one later. They have acme nuts for $20 but they want $20 to ship it and I can get a whole actuator shipped for $25, go figure.

I'm just tired of working on stuff!!!!! I had shoulder surgery and am behind on everything and it's been one thing after the other it seems. The car, the bedroom TV quit, actuator, lawn tractor, the Jeep and now the actuator again. I stayed up late to get the V8 Super programmed because I need to be doing other things, I'm sure you know how that goes.

I used Google cache to display this, otherwise you have to download it.

It lists a tube only which would get me going if it fits my motor but I expect it to cost too much, might as well get a new one. Do you guys know anything about it or the cost? #25 on the list.

25 6Z091 n/a V00212AK76 58.8 34.8 24 n/a n/a 14.0 lbs Tube

http://webcache.googleusercontent.c...ecrossreference.xls+&cd=2&hl=en&ct=clnk&gl=us

When I Google 6Z091 I get this which I assume is a photo of the tube only, but it could be for representation only and it's no longer available.

https://www.grainger.com/product/DAYTON-Tube-6Z091

Then they have this for $199, the one that's listed wrong in the drawing or I think it is, has to be.

DC Actuator 36 VDC, Full Load Speed 11 inches/minute, Gear Ration 19:1, Full Load Thurst 600 lbs, 1/15 HP, Current @ Full Load 3 Amps, Reed Switch. Substitute for Dayton 5A651.

http://estore.vonweise.com/vw7636vdcactuator-1.aspx

This one is $269.

Solar Panel/Satellite DC Actuator with Telescoping Tube Assembly. 24-36 VDC 1/15 HP Bidirectional Permanent Magnet Input Motor. 600 lbs. Full Load Thrust. Linear Velocity at Full Load Thrust 6.8 – 11.0 in/min. with 24 Inch Linear Stroke. Reed Switch Feedback Control. Limit Switches for overall stoke control. Enclosure Totally Enclosed Non-Ventilated. 19:1 Gearbox Ratio.

http://estore.vonweise.com/v76-5actuatorwithtelescopingtube.aspx

This one is $229 and not too clear on the details on length etc.

Solar Panel/Satellite DC Actuator with Telescoping Tube Assembly. 36 VDC 1/15 HP Bidirectional Permanent Magnet Input Motor. 300 lbs. Full Load Thrust. Linear Velocity at Full Load Thrust 11.0 in/min with 24 Inch Linear Stroke. Reed Switch Feedback Control. Limit Switches for Overall Stoke Control. Enclosure Totally Enclosed Non-Ventilated. 28:1 Gearbox Ratio

http://estore.vonweise.com/vw-24lcactuatorwithtelescopingtube.aspx

I've read a lot of bad, bad, things about the cheaper Super Jacks and the Maxi or whatever it's called, I forget. I've also read the thread on acme nut repair and I have a dremel but not a welder. I'd like to get it going cheap but I'll just buy a new one if I have to. I'm pooped and wanna watch TV, not work on it until Christmas.

I glued the magnets back in this motor and made a magnet wheel for it and converted it to a reed switch. It has been running great but I worry about the motor magnets, brushes etc and I want to be done with this. I hate to pay $20 for an acme nut and $20 to ship it (wow), then have the motor quit and end up buying a new one anyway, after installing a $40 acme nut in this one.

So, you are the guys to ask for certain, which of these is the right one or is that tube affordable?

I want my MTV (METV)!