Thanks. That's what I suspected. I plan to order the 8 pole one for the KTI actuator tomorrow. I think I'll leave the 4 pole one in the actuator for the TEK since the dish seems to be pointing accurately so far. For some reason the KTI pointing on the eastern sats gets messed up when I move the dish west of true south and then back to the east. It could be a grounding issue but I'm still waiting for an electrician to check things over. Someone mentioned that hall sensors tend to get destroyed by lightning surges so I better get the grounding checked before next spring. I'll keep throwing money at this until I get it fixed or run out of money.If the kit is a direct upgrade from a reed switch, the engineering has already been done.

replacing reed sensor with hall sensor

- Thread starter WhiteBeard

- Start date

- Latest activity Latest activity:

- Replies 52

- Views 7K

-

ENJOY SATELLITEGUYS AD FREE THIS FEBRUARY!

Thank you to the very generous support we got from our members in December we have decided to make the month of February AD FREE for everyone!

We want to see the true speed of our site and enjoy SatelliteGuys the way it was meant to be enjoyed!

If you would like to help us keep the lights on and keep enjoying the site AD FREE consider becoming a PUB MEMBER by CLICKING HERE.

THANK YOU TO EVERYONE FOR YOUR SUPPORT!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Man, I could get on a rant. Nothing bad has come since my hall conversion. The lightning surge thing might be yes or no. All of my string of stuff has an APC backup. Hall sensors (modern ones) have all sorts of protection built in. I haven't had one fail. But I also have a parts bin with them if one should.Thanks. That's what I suspected. I plan to order the 8 pole one for the KTI actuator tomorrow. I think I'll leave the 4 pole one in the actuator for the TEK since the dish seems to be pointing accurately so far. For some reason the KTI pointing on the eastern sats gets messed up when I move the dish west of true south and then back to the east. It could be a grounding issue but I'm still waiting for an electrician to check things over. Someone mentioned that hall sensors tend to get destroyed by lightning surges so I better get the grounding checked before next spring. I'll keep throwing money at this until I get it fixed or run out of money.

Just grab data sheet for one you might have hanging around. The actual hall component.

In the analog days tolerance for not being dead-on may have been okay. But with a signal of 9.5dB I may not get video, 9.8dB and up I do. So a worn out, sloppy ball screw or motor coupling...or gear train might not fly so well.

Reed switches are 'supposed' to be snap action. It takes a definite magnet pole flux to actuate them. Plus correct alignment to to pole. And a weak pole on sector magnet (I fought with one) invites count glitches and errors.

Hall sensors have a 'target'. The right one with Schmitt triggering on the output will snap on and snap off every single time. There is no contact bounce. A 0.1uf disc capacitor between the gnd and pulse output really cleans up the end pulse string (at motor controller). I've had enough industrial experience to be pretty familiar with sensors. Once I pondered fitting one of the ebay chinesium fake "Omron" encoders to my actuator motor.

I'm a little concerned about this since I read somewhere that actuators don't stand up well after 5 years of service. I hope that's not true. Who would want to replace and even recondition an actuator ever 5 years. I just got a quote from Venture for a 36 inch ball screw actuator with an 8 pole hall sensor for $385. Who would want to spend that every 5 years? I asked for the quote since I have a 24 inch actuator on the TEK and it looks like I could get better range on the arc with a 36 inch.So a worn out, sloppy ball screw or motor coupling...or gear train might not fly so well.

P/N: MA-834218543-36

Price: $385.00 ea. Ex-Works Dayton OH

Lead Time: 3-4 Weeks

99.9% sure expecting 5 years on the tek (supercrap) actuator will make you the laughing stock.I'm a little concerned about this since I read somewhere that actuators don't stand up well after 5 years of service. I hope that's not true. Who would want to replace and even recondition an actuator ever 5 years. I just got a quote from Venture for a 36 inch ball screw actuator with an 8 pole hall sensor for $385. Who would want to spend that every 5 years? I asked for the quote since I have a 24 inch actuator on the TEK and it looks like I could get better range on the arc with a 36 inch.

P/N: MA-834218543-36

Price: $385.00 ea. Ex-Works Dayton OH

Lead Time: 3-4 Weeks

I can't believe the headache from just buying a replacement motor I just had.

These things are out in the weather. If you don't do periodic maintenance on them, which 'who' used to back in the heyday, they will.

Of course you will get better arc with a longer actuator. Just make note where dish flop happens. You might even be able to move the the actuator mounting point out more towards the dish rim with a little creative fabrication.

That itself would lessen the actuator load plus increase your counts/degree of arc.

The dish is a TEK, the actuator is a 24" Venture. It's obvious that I can use a longer actuator for that dish. As for the KTI dish, I would have to be creative in order to use a 36 inch actuator. Even with the extender plate on the mount, I can't get past 121W without a dish flop. The actuator for the KTI is a 24" Venture also.99.9% sure expecting 5 years on the tek (supercrap) actuator will make you the laughing stock.

I can't believe the headache from just buying a replacement motor I just had.

These things are out in the weather. If you don't do periodic maintenance on them, which 'who' used to back in the heyday, they will.

Of course you will get better arc with a longer actuator. Just make note where dish flop happens. You might even be able to move the the actuator mounting point out more towards the dish rim with a little creative fabrication.

That itself would lessen the actuator load plus increase your counts/degree of arc.

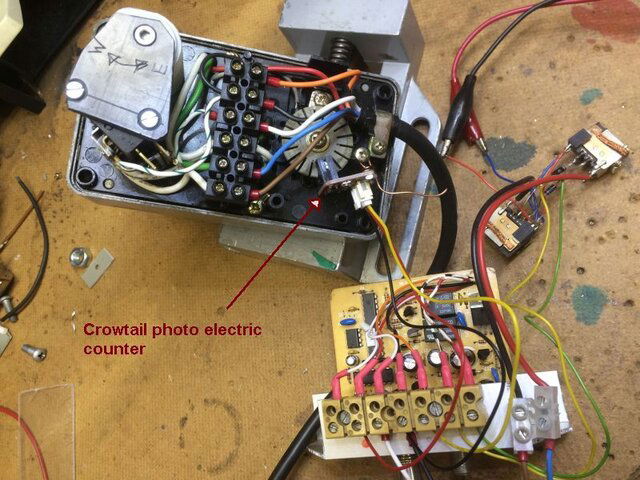

Where can I get these magnet wheels? I've been trying to find just a magnet wheel but it seems that I have to order a reed or hall sensor kit in order to get a magnet.Well no wonder I couldn't figure out what you were talking about. That so called hall effect sensor is the strangest thing I ever saw.I pulled a reed sensor apart and replaced the reed in the housing and changed the magnet wheel. This tripled the counts from the sensor.

View attachment 149513

I made those wheels. The clear one is two pieces of plexiglass glued together. I cut them with a hole saw. The magnets are cheap. K&J Magnetics Inc. kjmagnetics.comWhere can I get these magnet wheels? I've been trying to find just a magnet wheel but it seems that I have to order a reed or hall sensor kit in order to get a magnet.

I suppose that I could try my hand at doing that but I prefer factory built. I suppose that I need to get magnetic bars that end up sandwiched between the 2 pieces of plexiglass? And how did you cut that square hole in the center of the plexiglass? I'm surprised that I can't find a distributor of magnetic wheels outside of an actuator manufacturing firm. I get my actuators from Venture but they don't seem to be willing to sell just the wheel magnet.I made those wheels. The clear one is two pieces of plexiglass glued together. I cut them with a hole saw. The magnets are cheap. K&J Magnetics Inc. kjmagnetics.com

I used a 2" hole saw with a 1/4" pilot bit. This creates disks about 1-3/4" with a 1/4" hole in the center. I cut two of them from 1/16" thick material such as the plexi-glass. In one disk I drill (6 ) 3/16" holes around the edge to hold the disk magnets measuring 3/16" wide and 1/16" thick. (#D31-N42 from K&J Magnetics) I epoxy the disks together and insert the magnets (all polarized the same way) into the disk with the holes. I then take a small triangle file to the center hole and make the four corners of the square hole. The wheel is mounted magnet side to the reed switch.I suppose that I could try my hand at doing that but I prefer factory built. I suppose that I need to get magnetic bars that end up sandwiched between the 2 pieces of plexiglass? And how did you cut that square hole in the center of the plexiglass? I'm surprised that I can't find a distributor of magnetic wheels outside of an actuator manufacturing firm. I get my actuators from Venture but they don't seem to be willing to sell just the wheel magnet.

However this is a wheel I designed for a reed switch and have no idea about it working with your three wire sensor.

I was wondering if you had a square punch to do the center hole but a file will get the job done without looking too messy. As for your wheel, the same wheel is used on both the reed switch and hall switch in my actuators so your wheel ought to work fine with either switch. I still have a reed switch in one actuator and I'm trying to decide if I want to change it out for a hall sensor or just change out the magnet with more poles in order to increase the pulse count. That's why I've been searching for just the magnet. I'm not sure if a hall sensor will give better pointing accuracy or if it'll last longer than a reed. Not to mention having to supply it with 5VDC.I used a 2" hole saw with a 1/4" pilot bit. This creates disks about 1-3/4" with a 1/4" hole in the center. I cut two of them from 1/16" thick material such as the plexi-glass. In one disk I drill (6 ) 3/16" holes around the edge to hold the disk magnets measuring 3/16" wide and 1/16" thick. (#D31-N42 from K&J Magnetics) I epoxy the disks together and insert the magnets (all polarized the same way) into the disk with the holes. I then take a small triangle file to the center hole and make the four corners of the square hole. The wheel is mounted magnet side to the reed switch.

However this is a wheel I designed for a reed switch and have no idea about it working with your three wire sensor.

As I said before, that Hall Effect sensor you have doesn't operate like a hall effect sensor. It makes me think it's an adapter circuit with a reed switch trigger in it. Made for old movers that couldn't use a reed switch. But I don't have one of them to examine so I really don't know what's up with that.

But when I made my magnet wheel I re-did the reed switch too. I doubt that if you made a wheel identical to mine it would operate any of your sensors.

But when I made my magnet wheel I re-did the reed switch too. I doubt that if you made a wheel identical to mine it would operate any of your sensors.

False advertising? I'm not going to open one up to see what's inside although there wasn't any warranty implied.As I said before, that Hall Effect sensor you have doesn't operate like a hall effect sensor. It makes me think it's an adapter circuit with a reed switch trigger in it. Made for old movers that couldn't use a reed switch. But I don't have one of them to examine so I really don't know what's up with that.

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 3

- Views

- 1K

- Replies

- 10

- Views

- 2K

- Replies

- 8

- Views

- 730