I haven't switched to a hall sensor yet but I think I'll do that today since I'm having intermittent counting since replacing the reed. Everytime I check, my wiring is good and after reconnecting everything the sensor starts counting again. I wish I had a spare reed sensor to swap with. I really hate intermittents!

replacing reed sensor with hall sensor

- Thread starter WhiteBeard

- Start date

- Latest activity Latest activity:

- Replies 52

- Views 7K

-

ENJOY SATELLITEGUYS AD FREE THIS FEBRUARY!

Thank you to the very generous support we got from our members in December we have decided to make the month of February AD FREE for everyone!

We want to see the true speed of our site and enjoy SatelliteGuys the way it was meant to be enjoyed!

If you would like to help us keep the lights on and keep enjoying the site AD FREE consider becoming a PUB MEMBER by CLICKING HERE.

THANK YOU TO EVERYONE FOR YOUR SUPPORT!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I did the dirty deed and replaced the reed with a hall. So far so good. Kind of a bummer having to reprogram all the positions though. Next, I need to make this permanent though. I guess I need to order another hall sensor for the wife's dish - the counts really get messed up on hers but she has a much longer ribbon cable run.

Only when the V-Box is plugged in does it need to be powered on.Does 5VDC have to be constantly applied to the hall sensor or can it be switched off/on?

I suppose you tapped the 5VDC inside the Vbox/Gbox? I don't want to void the PR1200 warranty though.Only when the V-Box is plugged in does it need to be powered on.

Is it possible to open up a reed sensor enclosure and replace the reed with just a hall sensor itself or does the hall sensor need any additional circuity? The hall sensor enclosure seems to be the same as a reed sensor enclosure but, of course, the hall sensor needs 3 wires. I haven't opened up a hall sensor enclosure to see what's inside. I'm wondering if a simple swap out of a reed for a hall sensor can be done to save a few bucks or should I just part with the $50 to get a hall sensor assembly from Venture. Apparently, Venture won't sell the hall sensor without the magnet (which looks exactly like the magnet for the reed sensor) or without the standoff (which looks exactly like the standoff for the reed sensor).

Johnny. The kit would most probably be what you need for proper fitment. The poles on the magnet may even be different. With a hall sensor, magnet to sensor spacing and the 'target' on the hall sensor in relation to the magnet needs to be pretty precise. For my home brew hall interface there was a bit of oscilloscope waveform monitoring while running the motor while moving my pc board mounted hall sensor around (spacing and position) to get a nice square wave and least count errors.Is it possible to open up a reed sensor enclosure and replace the reed with just a hall sensor itself or does the hall sensor need any additional circuity? The hall sensor enclosure seems to be the same as a reed sensor enclosure but, of course, the hall sensor needs 3 wires. I haven't opened up a hall sensor enclosure to see what's inside. I'm wondering if a simple swap out of a reed for a hall sensor can be done to save a few bucks or should I just part with the $50 to get a hall sensor assembly from Venture. Apparently, Venture won't sell the hall sensor without the magnet (which looks exactly like the magnet for the reed sensor) or without the standoff (which looks exactly like the standoff for the reed sensor).

To answer your question more deeply. It might be possible to open the reed enclosure and swap it for a hall sensor.

Most any 3 or 4 lead hall could be used as long as its input voltage is in the 3-12 VDC range and has a Schmitt trigger output (I mistakenly mentioned Schottky output before) and can handle the current requirements of the the relay coil on the positioner input interface. Heck. I gutted an old pc fan to get mine. Then grabbed a datasheet.

Sorry for the delay getting a schematic and BOM up for you but back surgery has set me back a bit here. That comes first I guess.

Why try to save $50, and spend $200 worth of labor and a weeks time trying to get it "just right"? Spend the $50 and get it installed right the first time.

$50 here, $50 there, "snowballs" into $1000. But I'll probably spend the $50. I need other stuff that ranges from $200 to $1500 also. Just bought a $400 refrig to replace a working refrig because I couldn't get a door hinge for it (no longer manufactured). There's never enough money.Why try to save $50, and spend $200 worth of labor and a weeks time trying to get it "just right"? Spend the $50 and get it installed right the first time.

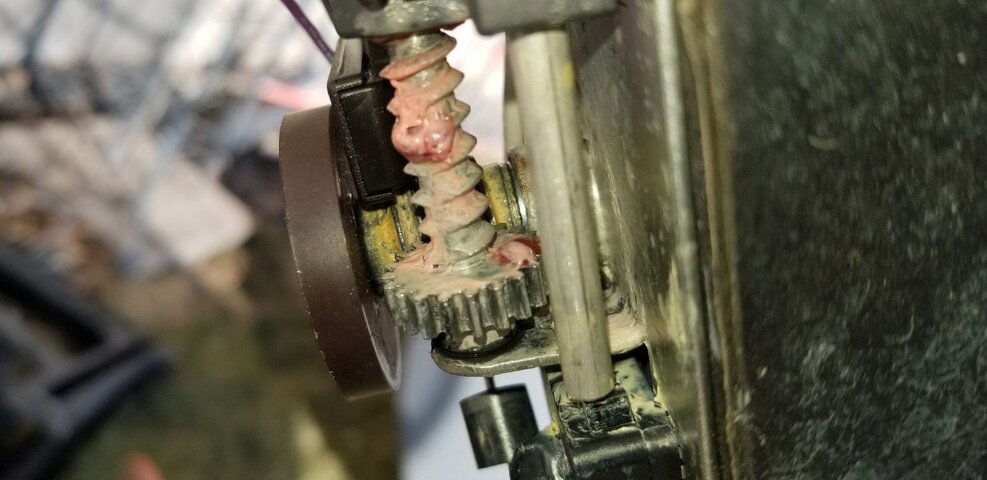

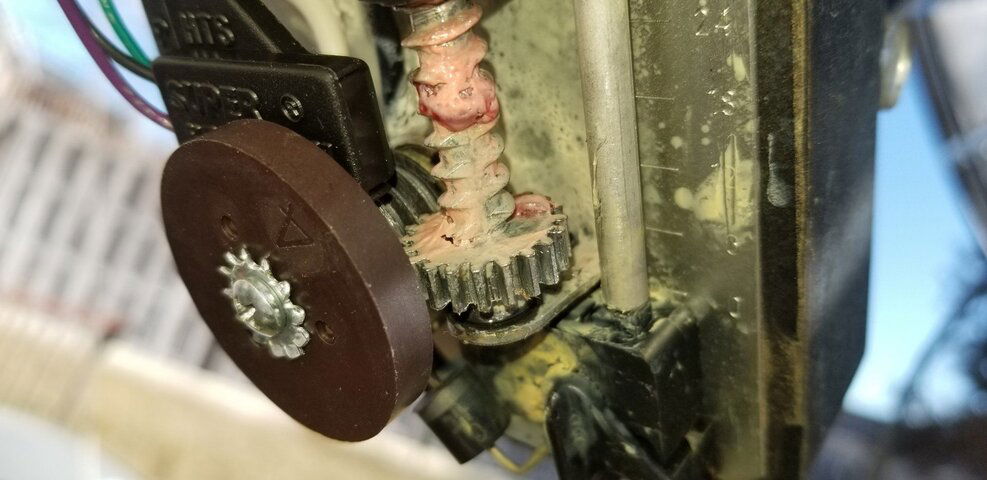

Would like to see pictures of all that. Hard to visualize all what you're saying without having looked at one of those actuators before. One thing I have run into while fiddling around with sensors is the old actuators have a 5 wire barrier block and the reed switch ones have a 4 wire barrier block. I have had to reposition one to accommodate a new sensor. I have an old Venture actuator that uses a cog drive belt. Looks just like ones that don't have a belt. The belt is old and about to break in the one I have. I have yet to find any replacements for it either.Is it possible to open up a reed sensor enclosure and replace the reed with just a hall sensor itself or does the hall sensor need any additional circuity? The hall sensor enclosure seems to be the same as a reed sensor enclosure but, of course, the hall sensor needs 3 wires. I haven't opened up a hall sensor enclosure to see what's inside. I'm wondering if a simple swap out of a reed for a hall sensor can be done to save a few bucks or should I just part with the $50 to get a hall sensor assembly from Venture. Apparently, Venture won't sell the hall sensor without the magnet (which looks exactly like the magnet for the reed sensor) or without the standoff (which looks exactly like the standoff for the reed sensor).

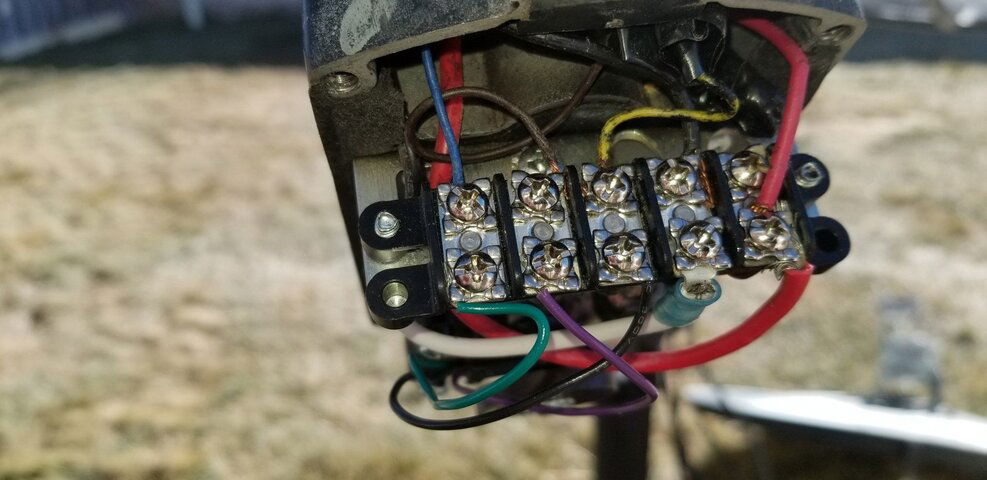

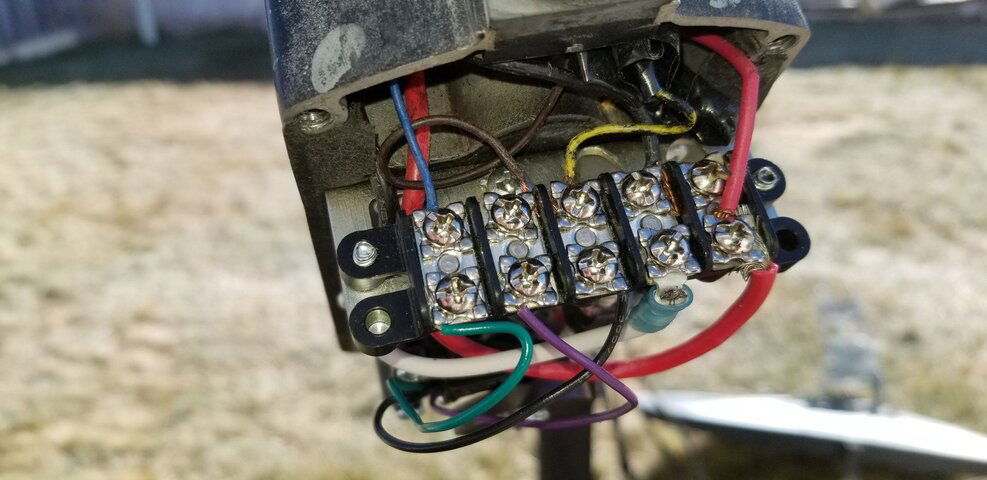

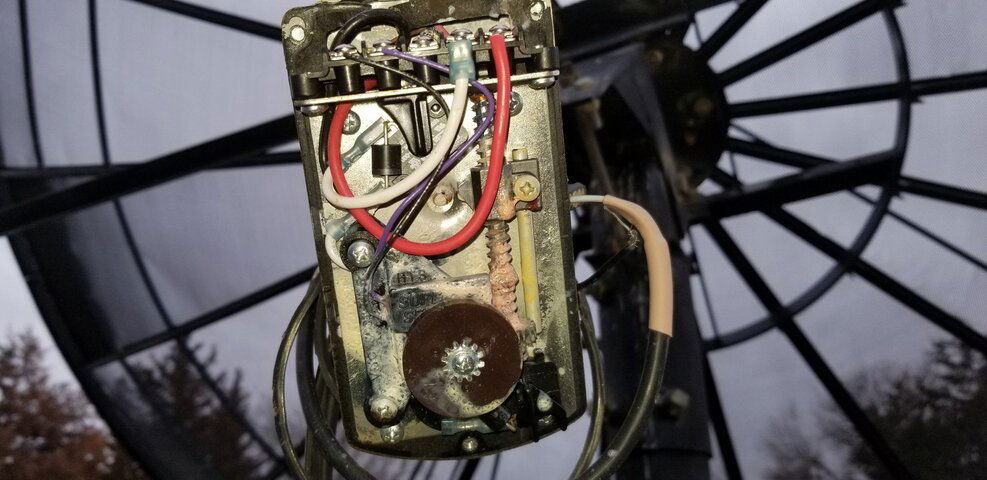

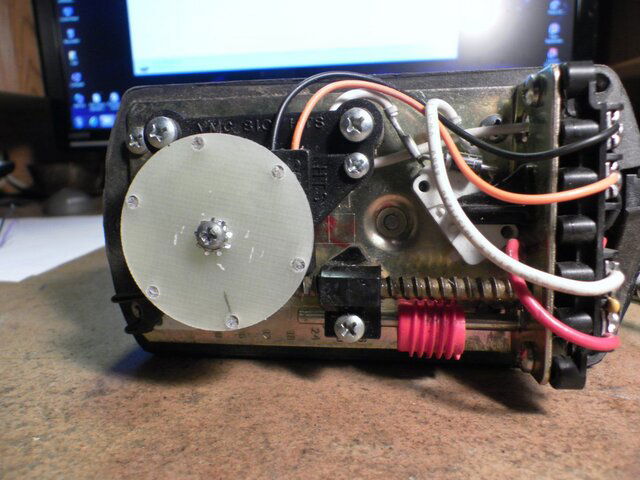

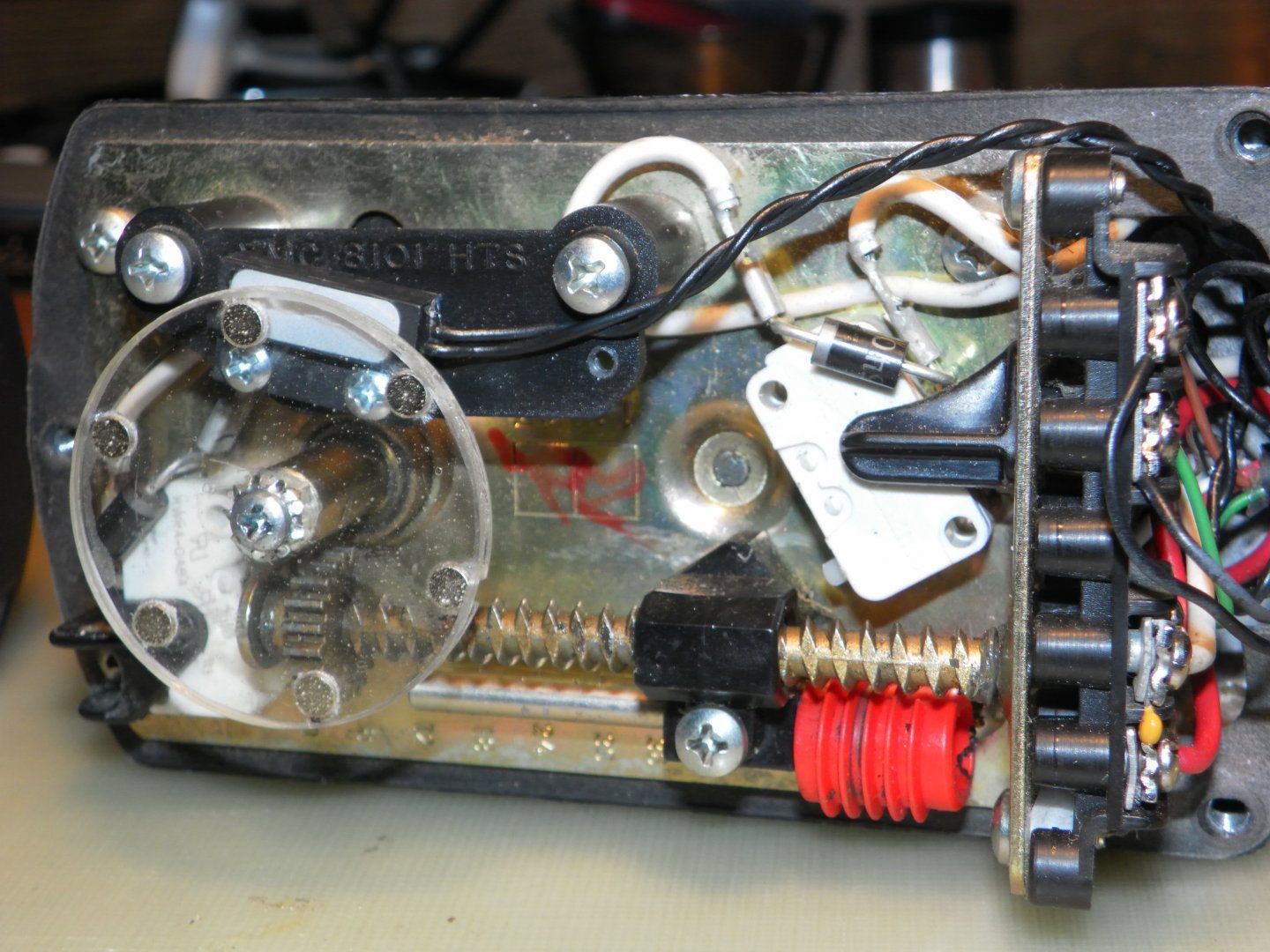

Not sure of what you're asking for but here images from both the actuator for the TEK2000 and KTI. Both actuators are Venture. The TEK2000 is using a hall sensor and the KTI is using a reed. They both mount the same and look the same except the hall has 3 wires and the reed 2 wires.Would like to see pictures of all that. Hard to visualize all what you're saying without having looked at one of those actuators before. One thing I have run into while fiddling around with sensors is the old actuators have a 5 wire barrier block and the reed switch ones have a 4 wire barrier block. I have had to reposition one to accommodate a new sensor. I have an old Venture actuator that uses a cog drive belt. Looks just like ones that don't have a belt. The belt is old and about to break in the one I have. I have yet to find any replacements for it either.

Attachments

More images. You'll note that the magnet for the reed and the hall have the number 4 etched into them. Heh, I probably should have wiped things down.

Attachments

Well no wonder I couldn't figure out what you were talking about. That so called hall effect sensor is the strangest thing I ever saw.Not sure of what you're asking for but here images from both the actuator for the TEK2000 and KTI. Both actuators are Venture. The TEK2000 is using a hall sensor and the KTI is using a reed. They both mount the same and look the same except the hall has 3 wires and the reed 2 wires.

I guess the number imprinted on the magnet wheel indicates how often it'll trigger the pulse? And why did you change the location of the reed?

The new magnet wheel is larger in diameter and the new reed was placed so it is directly under the magnets as they pass. This also enables me to double the counts because of the way a magnetic reed switch operates. The actuator has an 8 pitch screw so the stock 4 pulse magnet yields 32 counts per inch. With the double counting 6 magnet wheel (12 pulses) X the 8 pitch screw you get 96 counts per inch.And why did you change the location of the reed?

Attachments

I have done this mod using a molded body switch off the shelf with my new magnet wheel. Also 96 counts per inch.

Mine is pretty much the same using an old VCR gear. Hey, what the hay! Right?

But it has 20 neodymimium disc magnets around the edge with opposing poles super glued and then buried in clear 5 minute Epoxy. Don't know about counts/inch but from west limit (just below 133W) to right past 47.5W East limit I'm getting right at 1550 counts.

But it has 20 neodymimium disc magnets around the edge with opposing poles super glued and then buried in clear 5 minute Epoxy. Don't know about counts/inch but from west limit (just below 133W) to right past 47.5W East limit I'm getting right at 1550 counts.

I wouldn't mind having a more accurate count even for C band. But I'm not sure if I want to put in the time and effort to do what you did. If all it takes is simply putting on a different magnet then that'll be worth my time. But if I have to mess with orientation of the switch itself or some other modification then I'm "out". I suppose that what you did would work with a hall sensor? I plan to replace the reed in the other actuator with a hall sensor and keep the reeds for backup.I have done this mod using a molded body switch off the shelf with my new magnet wheel. Also 96 counts per inch.

I just got this response from Venture for a hall effect sensor with 6 or 8 magnet wheels and I figured people here might be interested. Not sure if it'll improve pointing accuracy, though, but the price is the same for 4, 6 and 8 pole wheels. I don't know if there needs to be any fiddling to be done to make them work properly but I assume that the engineering testing has already been done.

P/N: 8102-10 (6 pole)

Price: $50.00 ea. Ex-Works Dayton OH

Lead Time: 1-2 Days

P/N: 8102-18 (8 pole)

Price: $50.00 ea. Ex-Works Dayton OH

Lead Time: 1-2 Days

Terms: Credit Card prior to shipping

Please Email order confirmation along with Shipping/Billing address & phone number.

We will call for credit card.

Renee Davis

Venture Mfg. Co. / 3636 Dayton Park Dr. / Dayton, OH 45414

Tel: 937-233-8792 ext. 440 / TF: 866-365-1957 / Fax: 937-233-8485

Some people say I should get an oscilloscope to verify the pulse shape/quality but there's a lot of things I need/want.

P/N: 8102-10 (6 pole)

Price: $50.00 ea. Ex-Works Dayton OH

Lead Time: 1-2 Days

P/N: 8102-18 (8 pole)

Price: $50.00 ea. Ex-Works Dayton OH

Lead Time: 1-2 Days

Terms: Credit Card prior to shipping

Please Email order confirmation along with Shipping/Billing address & phone number.

We will call for credit card.

Renee Davis

Venture Mfg. Co. / 3636 Dayton Park Dr. / Dayton, OH 45414

Tel: 937-233-8792 ext. 440 / TF: 866-365-1957 / Fax: 937-233-8485

Some people say I should get an oscilloscope to verify the pulse shape/quality but there's a lot of things I need/want.

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 3

- Views

- 1K

- Replies

- 10

- Views

- 2K

- Replies

- 8

- Views

- 730