you can also hook a meter up to the reed switch and check for continuity while you move it. meter should beep as it runs.

crackt out,.

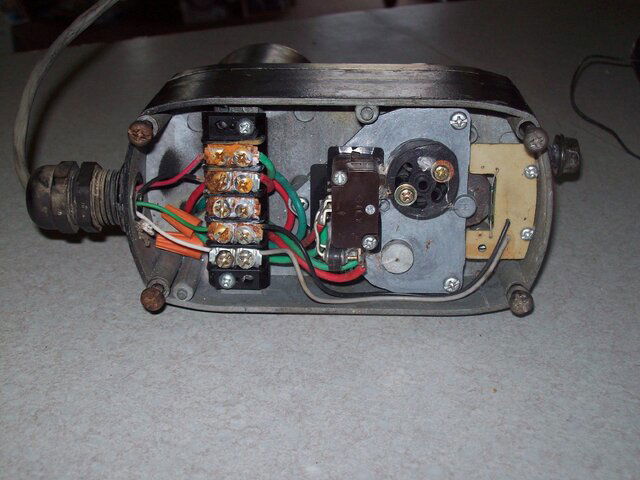

that is not a reed switch, that is a mirco-switch.

what you have their is their PAN, is the 1st transition over from a 1 to 10K pot to a pulse that a receiver could log the actuator position of the sats. an it works on the same princeapal as a reed switch, it is just mechanical instead of a magnet wheel moving over the reed.

if you look at the bottom of the gear box their is a star that come out of gear housing, an the button on the mirco-switch should be depressed when it comes in contact of those star points. now most mirco-switches have 2 wires out of them, unless they are a double poll switch, or they could be using the other wire for a ground, a multi-meter will tell you that an should be able to trouble shoot the pulses from the mirco-switch.

at 1st when I look at you're picture thought you had a optic sensor, but after closer look no you don't, an that was because of the color code on the wires.

a lot of companys that produce actuators back in the early to mid 80's where using this set up, an they where very dependable too, untill they started to standardize the satellite industry, with wiring color codes, lnb's an reed switches that could be inter changed from all of the different receivers a satellite systems that where produced.

![P120610_14.51_[01].jpg](https://cdn.satelliteguys.us/xen/data/attachments/41/41968-a8f21504000392f9e1262cd34349db55.jpg?hash=qPIVBAADkv)