update

i took down the dish yesterday, it went pretty smoothly, with two friend and the former owner

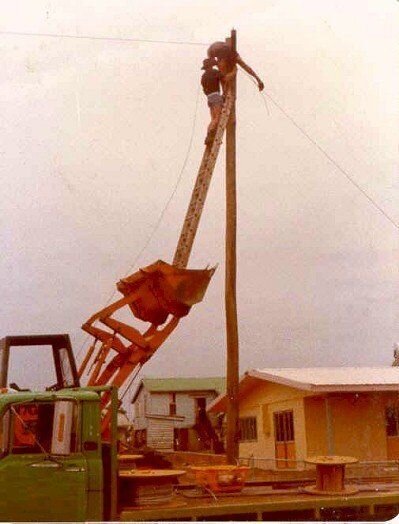

.Sorry for the pictures, couldnt bring the girlfriend with us. We had a little problem finding the right way to take it down. My toughts on getting it apart on the post went away really fast when a saw my 6'5 friend just barely getting the mount.

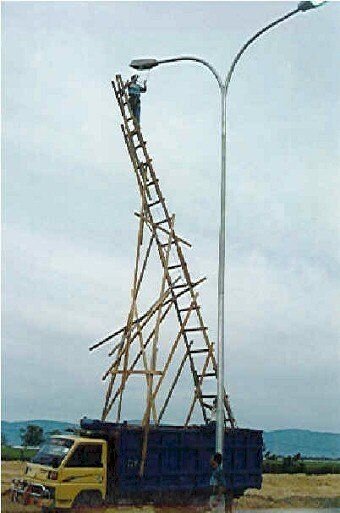

After having an argument with the owner about not messing is shed roof and the way he wanted to take it down : he wanted to use a ladder as a crane... and I wanted to keep the dish round

We remove the feedhorn and the quadpod first, there was the only bolt we had to cut, with an battery impact all bolts were pulled easy. I will change all nuts and bolts when ill put it back at my place!!

Finaly we used a mounting hole on the post as a pulley and tie it to the ring behind the dish , and slowly sliding it down to the ground. Succes!!!

After putting it on the ground , the owner kids started to kick it on the mesh. lets say hes father didnt left him the time to kick it twice!! lol

I opened the cap on top of the feedhorn, to find a califonia amp C/Ku linear feed. is it a good quality piece to start with? Its marked as a Startrack dish, anyone know anything about this brand?

a few other question, is the vonweise actuator i got with it a good one, or should get a new one. It gets its power from something that looks like a extension cord including the plugs. What should i buy for this 10ft dish.

What could be the expected arc i should get with it, it will be installed at 71 3''W and 48 24''N. Is the lenght of the actuator have an effect on the range of the dish?

thanks for all your inputs it went really great!!!