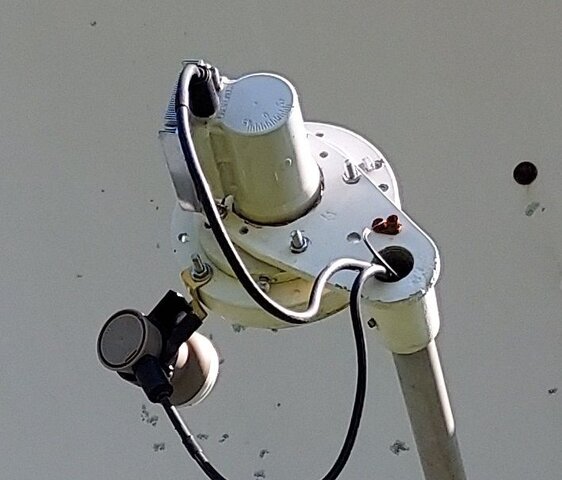

The dish is loose because of worn bearings and a very loose actuator, can I get the bearings for it? And if the position control box works what actuator can I use with it? If not what actuator and box should I get? The LNA is still up in the air literally (

I need to get a ladder to reach it so I can pull the cover off to inspect it. Any thoughts on the photos and video if it posts? A link to the video of the play in it it's to large to attach.

View: https://drive.google.com/folderview?id=1ef8I9viRxFLFDRr8eG-c71Rm_7HahtNo

I need to get a ladder to reach it so I can pull the cover off to inspect it. Any thoughts on the photos and video if it posts? A link to the video of the play in it it's to large to attach.

View: https://drive.google.com/folderview?id=1ef8I9viRxFLFDRr8eG-c71Rm_7HahtNo

Attachments

-

PXL_20211231_185940985.jpg134.4 KB · Views: 256

PXL_20211231_185940985.jpg134.4 KB · Views: 256 -

PXL_20211231_185117715.jpg342.6 KB · Views: 249

PXL_20211231_185117715.jpg342.6 KB · Views: 249 -

PXL_20211231_185122890.jpg170 KB · Views: 237

PXL_20211231_185122890.jpg170 KB · Views: 237 -

PXL_20211231_185127718.jpg231.5 KB · Views: 251

PXL_20211231_185127718.jpg231.5 KB · Views: 251 -

PXL_20211231_185134267.jpg335.7 KB · Views: 225

PXL_20211231_185134267.jpg335.7 KB · Views: 225 -

PXL_20211231_185152473.jpg232 KB · Views: 236

PXL_20211231_185152473.jpg232 KB · Views: 236 -

PXL_20211231_185242058.jpg78.5 KB · Views: 224

PXL_20211231_185242058.jpg78.5 KB · Views: 224 -

PXL_20211231_185201152.jpg136.6 KB · Views: 224

PXL_20211231_185201152.jpg136.6 KB · Views: 224 -

PXL_20211231_185246230.jpg146.3 KB · Views: 223

PXL_20211231_185246230.jpg146.3 KB · Views: 223 -

PXL_20211231_185823719.jpg283.3 KB · Views: 245

PXL_20211231_185823719.jpg283.3 KB · Views: 245 -

PXL_20211231_185827926.jpg237.1 KB · Views: 230

PXL_20211231_185827926.jpg237.1 KB · Views: 230 -

PXL_20211231_185839269.jpg72.8 KB · Views: 228

PXL_20211231_185839269.jpg72.8 KB · Views: 228 -

PXL_20211231_185934671.jpg121.6 KB · Views: 232

PXL_20211231_185934671.jpg121.6 KB · Views: 232