I came across a mint condition 10' mesh Channel Master for a good price. Got this dish home, set up on a small temporary pole I have out back. Now I need to get the mount home :-(

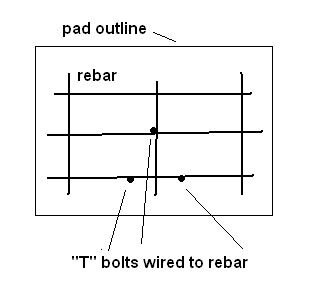

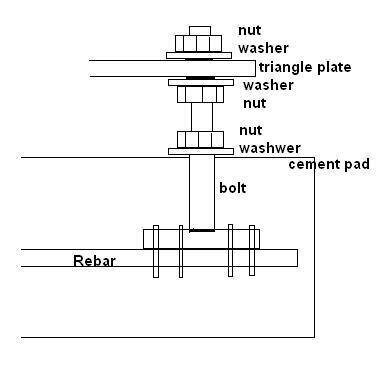

The dish sat on a concrete pad with one of those mounts that was bolted to the pad with heavy threaded rod for adjustment when needed. I believe it is about 5' diameter, not sure how thick...gotta be about 4" thick.

I'm looking for suggestions of how to move this think and get it into a truck. There's plenty snow back there and I don't think we'll be getting the truck back there.

My plan so far, is to loosen it up with a heavy lining bar and get something underneath it to help it slide. Its got heavy wire "handles" sunk right into the concrete so I'm thinking a few guys and a heavy strap to those handles *should* be able to get this thing dragged up to the truck in the front yard.

From there, we'll winch it up using a come-along onto a couple 2x6's into the truck.

Any better suggestions anyone might have used? perhaps something better to slide under it to help it slide on the snow.

I'll have 4 guys to move it, one of them being my brother who could likely bench press me with 1 hand. He thinks it must weigh about 800lbs.

thoughts??

The dish sat on a concrete pad with one of those mounts that was bolted to the pad with heavy threaded rod for adjustment when needed. I believe it is about 5' diameter, not sure how thick...gotta be about 4" thick.

I'm looking for suggestions of how to move this think and get it into a truck. There's plenty snow back there and I don't think we'll be getting the truck back there.

My plan so far, is to loosen it up with a heavy lining bar and get something underneath it to help it slide. Its got heavy wire "handles" sunk right into the concrete so I'm thinking a few guys and a heavy strap to those handles *should* be able to get this thing dragged up to the truck in the front yard.

From there, we'll winch it up using a come-along onto a couple 2x6's into the truck.

Any better suggestions anyone might have used? perhaps something better to slide under it to help it slide on the snow.

I'll have 4 guys to move it, one of them being my brother who could likely bench press me with 1 hand. He thinks it must weigh about 800lbs.

thoughts??