I don't usually browse this forum too often, but I know there are a few Birdview users on here and I need help with a very odd and infrequent problem.

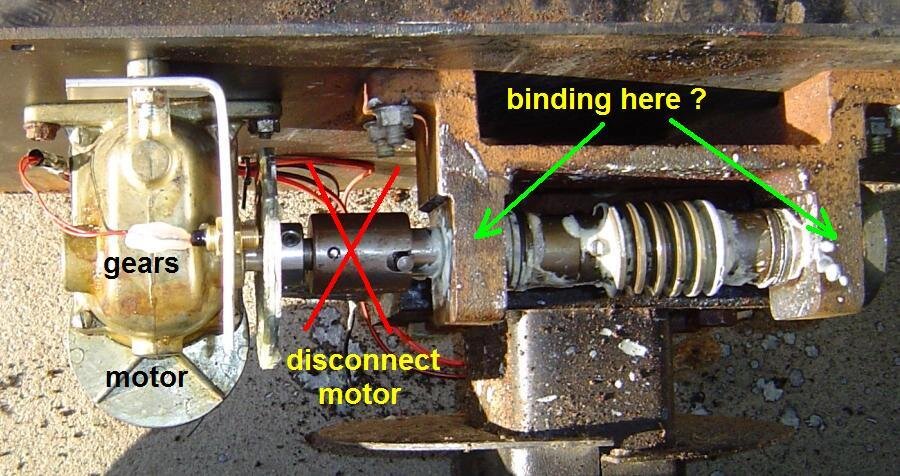

Simply put, my dish has "locked" up. This happens a couple times a year and I am fairly certain it has something to do with the worm drive or bearings on the ends of the worm drive. I am not sure if "worm" is the proper term, but I am referring to the spinning shaft that rides the flyweel mount.

All necessary components are kept well lubricated with white lithum grease and the motor is running fine. I am able to get the dish moving again, but only after I remove the motor and manually crank on the worm drive with a vise-grip. I would LOVE if I could stop making 3 hour trips across the state to my parents' home (where the dish is located) to fix problems like this.

I would like to know just what those "wheel bearings" on each end of the worm drive do. It appears that one side locks up when the dish is moving one direction, and the then vice versa.

It's a very frustrating problem that I just cannot figure out.

Thanks for any input!

Kevin

Simply put, my dish has "locked" up. This happens a couple times a year and I am fairly certain it has something to do with the worm drive or bearings on the ends of the worm drive. I am not sure if "worm" is the proper term, but I am referring to the spinning shaft that rides the flyweel mount.

All necessary components are kept well lubricated with white lithum grease and the motor is running fine. I am able to get the dish moving again, but only after I remove the motor and manually crank on the worm drive with a vise-grip. I would LOVE if I could stop making 3 hour trips across the state to my parents' home (where the dish is located) to fix problems like this.

I would like to know just what those "wheel bearings" on each end of the worm drive do. It appears that one side locks up when the dish is moving one direction, and the then vice versa.

It's a very frustrating problem that I just cannot figure out.

Thanks for any input!

Kevin