Some have taken to fabricating their own parts in a pinch. Hopefully they'll can find something you can use.

I figured this was going to be a custom rebuild job. ... just need to keep costs commensurate. ... so far I'm in for two bills for the polar rmount & actuator (tek2000) and still need. ..

ground mounting pole

Cement

Lnb

Lnb supports

Misc nuts bolts

For 2 bills or less, you can probably find a used 10' with matching parts . In my area they are dwindling but I can still locate at least 5 that are not used. For the mounting pole you can probably pick one up at a scrap yard depending on how high you need to mount it.

I would think twice about using tek2000 for parts. A complete matched assembly from them might be ok, but I wouldn't use their polar mount (said to be weak) on a heavy American made dish.

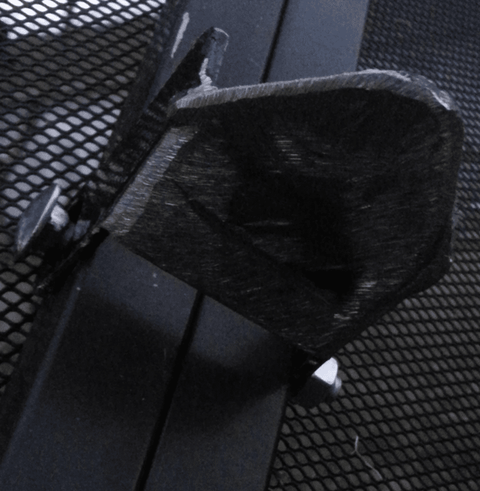

even with the quality forewarnings, I was still quite surprised

even with the quality forewarnings, I was still quite surprised

........ the parts appear to be poor knock-offs

........ the parts appear to be poor knock-offs

, thats why I assume they sent me something scheduled to be reworked or from the training pile - since I didn't order a complete dish kit. ....... another lesson learned so its all good......

, thats why I assume they sent me something scheduled to be reworked or from the training pile - since I didn't order a complete dish kit. ....... another lesson learned so its all good...... - top 10 lifetime best purchase in the "don't need it, but want it anyway" category)

- top 10 lifetime best purchase in the "don't need it, but want it anyway" category)