I have decided to add another 10 footer to the farm and run it with a H to H instead of an actuator. The H to H motors generally don't do well here in the Canadian winters. I am going to give it a try with the assistance of a heat tape.

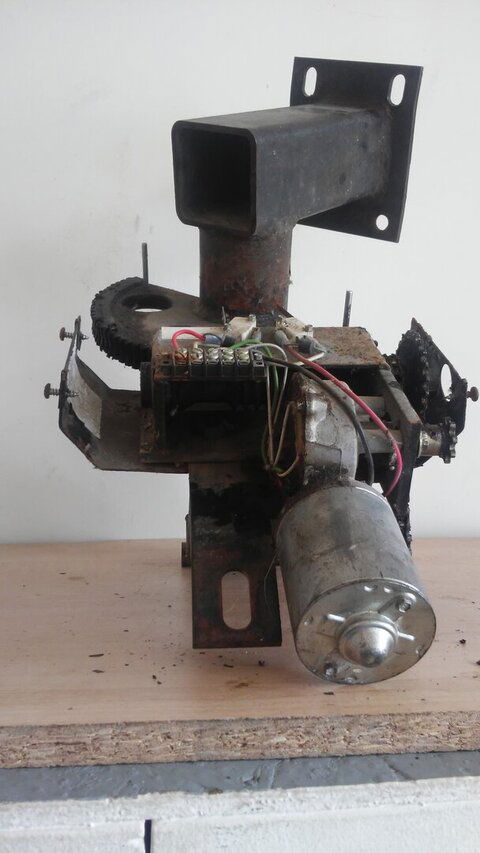

I had this AJAX in storage which I removed from a dish and replaced with a Von Weise. As soon as it got cold, it wouldn't move.

Connected just the motor to a mover and the motor turns fine and counts.

My plan is to disassemble everything and remove all the old grease and crud. I will then get the housing sandblasted and give it a fresh coat of paint.

Any advice before I start from someone who has done this before?

I appreciate all feedback.

I had this AJAX in storage which I removed from a dish and replaced with a Von Weise. As soon as it got cold, it wouldn't move.

Connected just the motor to a mover and the motor turns fine and counts.

My plan is to disassemble everything and remove all the old grease and crud. I will then get the housing sandblasted and give it a fresh coat of paint.

Any advice before I start from someone who has done this before?

I appreciate all feedback.