Titanium Satellite Hardware Modification: 22KHz/DiSEqC 1.2 Pass-through and Increased STB Compatibil

- Thread starter Titanium

- Start date

- Latest activity Latest activity:

- Replies 47

- Views 10K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Please reply by conversation.

Hi by any chance do you have a picture to show the connection you did? ThanksI'd say I have the same amount of time into the repair. The only real challenge is the resistor R106. I put the resistor and capacitor in series to replace C132 on the back of the mainboard. I also put the disc capacitor on the back. I pulled the heatsink off U102 to get better access to R106.

I was sure I did but I can't find any. hhmmmmmm???? I think I take too many pictures.Hi by any chance do you have a picture to show the connection you did? Thanks

One never can take to many pictures!I was sure I did but I can't find any. hhmmmmmm???? I think I take too many pictures.

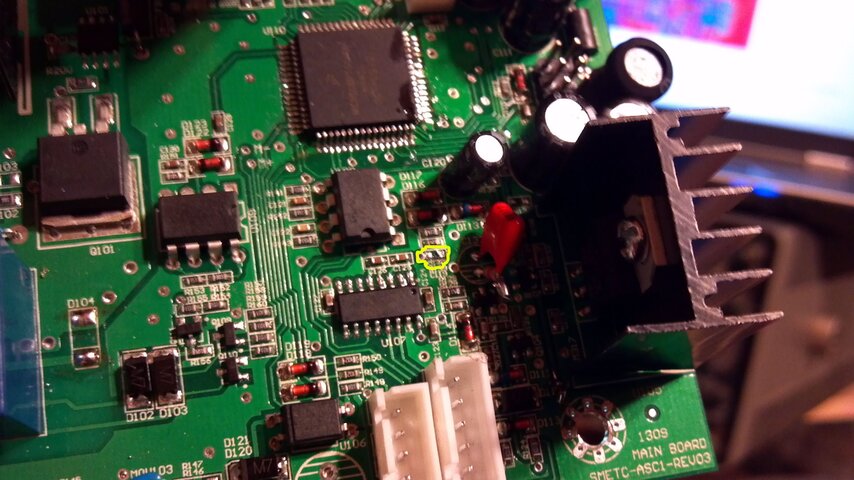

Spoke with Bzrut and he is a cell PCB tech hired to do the posted mods by someone who was gifted the original unit. Bzrut certainly has the tools and skill-set to make the modifications!

I shared with him a few additional mods that will bring the original PCB into full compliance with the current rev. He is taking photos, documenting the repair and will share them here when completed.

Thanks Bzrut!

I shared with him a few additional mods that will bring the original PCB into full compliance with the current rev. He is taking photos, documenting the repair and will share them here when completed.

Thanks Bzrut!

hey guys,

here is how i did the modification

i have rigorously tested it and it is working great and passing diseqc commands to my switch like its going for a touchdown.

i didn't use surface mount stuff, it just seems to take all the colour out of the circuit board.

plus i went into this project wanting to find the easiest way to do it right so other people could do it as well.

I AM NOT TELLING ANYONE TO TRY THIS, IF YOU DO, IT IS AT YOUR OWN RISK!!!!!!!!

anyway,

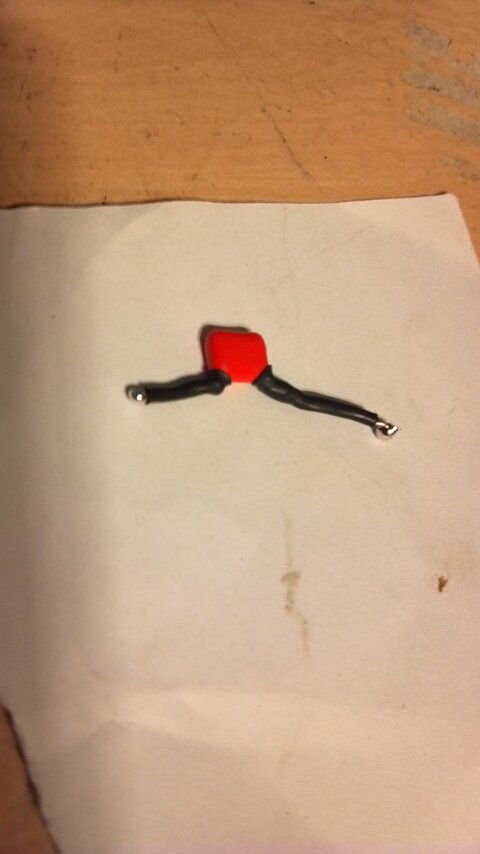

parts i used, (see pic 1)

3.3k ohm 1/8 watt resistor - orange, orange, red, gold

4.7k ohm 1/8 watt resistor - yellow, violet, red, gold

10nF (0.01uF) non-electrolytic capacitor - 103

100nF (0.1uF) non-electrolytic capacitor - 104

(all scavenged out of an old crt computer monitor)

small piece of heat shrink tubing

tools i used, (pic 2)

soldering iron

solder sucker

0.8mm 60/40 rosin core solder

(NOT rohs compliant, maybe a bit poisonous, but solder without lead sux... )

)

toenail clippers

allen wrench

phillips screw driver

small tray for screws and parts

For DiSEqC pass-through

step 1. unplug and unhook everything from the asc1

step 2. remove the screws on the bottom

step 3. ease it apart enough to unplug the wires from the main board

step 4. remove 4 screws holding the main board and remove the board

step 5. heat up your soldering iron and remove the small surface mount capacitor on the back of the main board

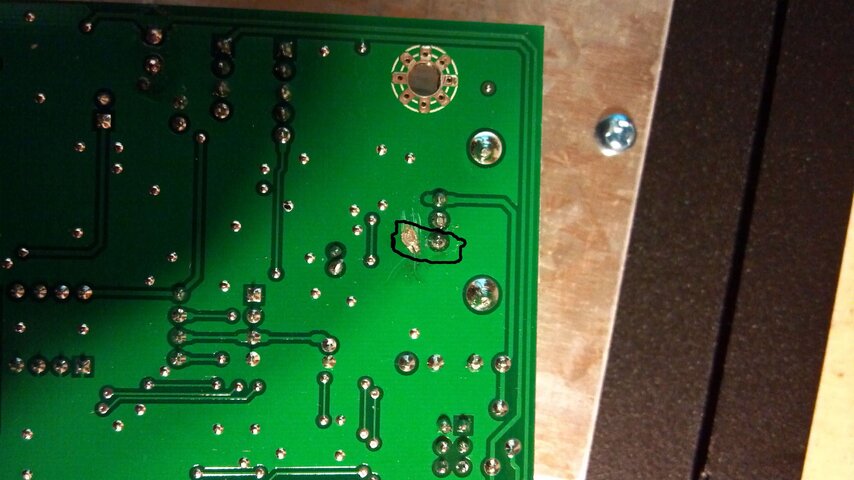

already removed but location shown in (pic 3)

step 6. remove the electrolytic capacitor c132 (pic 4)

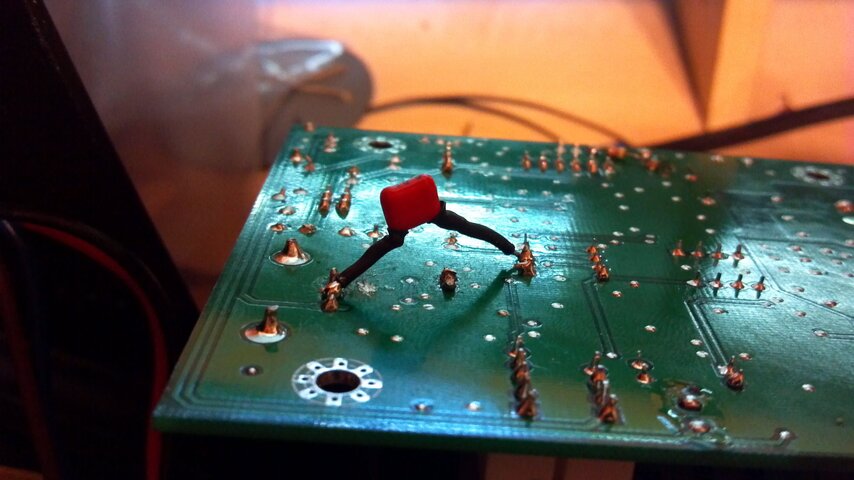

step 7. twist 1 leg of the 100nF cap and the 3.3k ohm resistor, solder them together, then use the toenail clippers to shorten the leads you just soldered (pic 5)

step 8. solder this in place of the electrolytic capacitor you removed in step 6 (pic 6) and clip the excess length off the leads with the toenail clippers (pic 7)

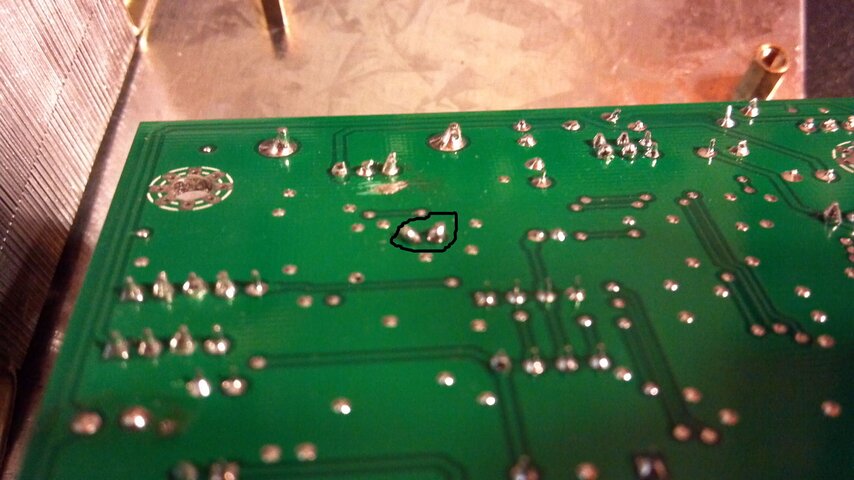

step 9. remove r106 being very careful not to disturb r105 (pic 8)

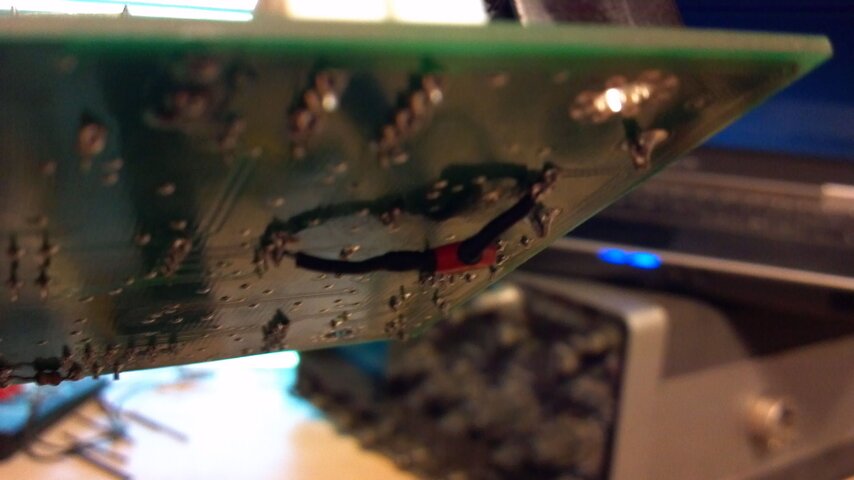

step 10. solder the 4.7k ohm resistor on the back of the board from the negative side of the large electrolytic capacitor c107 to the closest leg of u102 (pic 9)

To increase sensitivity to DiSEqC commands

step 1. remove the small surface mount capacitor c119

already removed, but location shown in (pic 10)

step 2. put heat shrink tubing on the legs of the 10nF capacitor, heat it to make it shrink, then put a small ball of solder on the end of each leg. (pic 11)

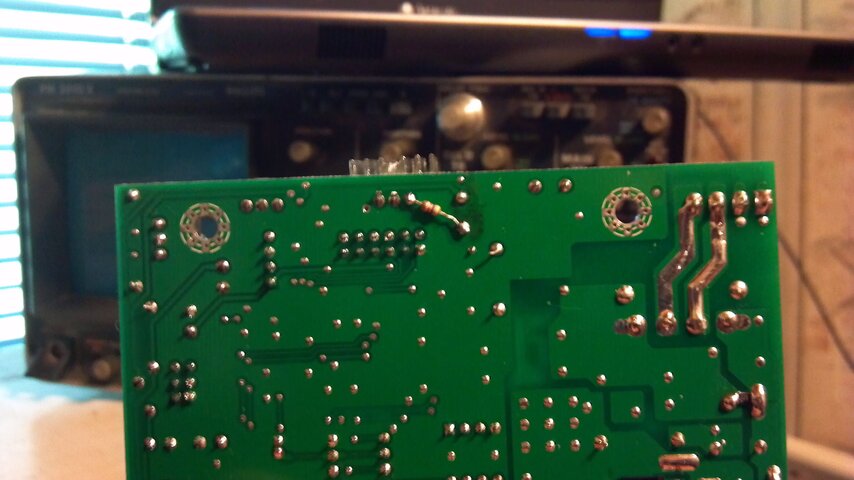

step 3. solder 1 leg of the 10nF capacitor to the centre pin of u105 on the back of the board and solder the other leg to pin 2 of u108 on the back of the board (pic 12). notice the angle the legs are at in (pic 13) just after soldering. this will help keep the legs from shorting against anything when the capacitor is bent down to its permanent location (pic 14).

note that there is still a gap between the legs and the board in pic 14 to help insure there is no accidental contact with anything else.

all in all, not to hard to do. it took longer to post this than it did to do the mods!!

hope this helps,

Denny

here is how i did the modification

i have rigorously tested it and it is working great and passing diseqc commands to my switch like its going for a touchdown.

i didn't use surface mount stuff, it just seems to take all the colour out of the circuit board.

plus i went into this project wanting to find the easiest way to do it right so other people could do it as well.

I AM NOT TELLING ANYONE TO TRY THIS, IF YOU DO, IT IS AT YOUR OWN RISK!!!!!!!!

anyway,

parts i used, (see pic 1)

3.3k ohm 1/8 watt resistor - orange, orange, red, gold

4.7k ohm 1/8 watt resistor - yellow, violet, red, gold

10nF (0.01uF) non-electrolytic capacitor - 103

100nF (0.1uF) non-electrolytic capacitor - 104

(all scavenged out of an old crt computer monitor)

small piece of heat shrink tubing

tools i used, (pic 2)

soldering iron

solder sucker

0.8mm 60/40 rosin core solder

(NOT rohs compliant, maybe a bit poisonous, but solder without lead sux...

toenail clippers

allen wrench

phillips screw driver

small tray for screws and parts

For DiSEqC pass-through

step 1. unplug and unhook everything from the asc1

step 2. remove the screws on the bottom

step 3. ease it apart enough to unplug the wires from the main board

step 4. remove 4 screws holding the main board and remove the board

step 5. heat up your soldering iron and remove the small surface mount capacitor on the back of the main board

already removed but location shown in (pic 3)

step 6. remove the electrolytic capacitor c132 (pic 4)

step 7. twist 1 leg of the 100nF cap and the 3.3k ohm resistor, solder them together, then use the toenail clippers to shorten the leads you just soldered (pic 5)

step 8. solder this in place of the electrolytic capacitor you removed in step 6 (pic 6) and clip the excess length off the leads with the toenail clippers (pic 7)

step 9. remove r106 being very careful not to disturb r105 (pic 8)

step 10. solder the 4.7k ohm resistor on the back of the board from the negative side of the large electrolytic capacitor c107 to the closest leg of u102 (pic 9)

To increase sensitivity to DiSEqC commands

step 1. remove the small surface mount capacitor c119

already removed, but location shown in (pic 10)

step 2. put heat shrink tubing on the legs of the 10nF capacitor, heat it to make it shrink, then put a small ball of solder on the end of each leg. (pic 11)

step 3. solder 1 leg of the 10nF capacitor to the centre pin of u105 on the back of the board and solder the other leg to pin 2 of u108 on the back of the board (pic 12). notice the angle the legs are at in (pic 13) just after soldering. this will help keep the legs from shorting against anything when the capacitor is bent down to its permanent location (pic 14).

note that there is still a gap between the legs and the board in pic 14 to help insure there is no accidental contact with anything else.

all in all, not to hard to do. it took longer to post this than it did to do the mods!!

hope this helps,

Denny

Attachments

-

pic 1.jpg372.7 KB · Views: 264

pic 1.jpg372.7 KB · Views: 264 -

pic 2.jpg639.4 KB · Views: 285

pic 2.jpg639.4 KB · Views: 285 -

pic 3.jpg551.6 KB · Views: 276

pic 3.jpg551.6 KB · Views: 276 -

pic 4.jpg790.1 KB · Views: 280

pic 4.jpg790.1 KB · Views: 280 -

pic 5.jpg71.3 KB · Views: 253

pic 5.jpg71.3 KB · Views: 253 -

pic 6.jpg548.4 KB · Views: 262

pic 6.jpg548.4 KB · Views: 262 -

pic 7.jpg613.8 KB · Views: 257

pic 7.jpg613.8 KB · Views: 257 -

pic 8.jpg623.2 KB · Views: 255

pic 8.jpg623.2 KB · Views: 255 -

pic 9.jpg448.1 KB · Views: 249

pic 9.jpg448.1 KB · Views: 249 -

pic 10.jpg641.3 KB · Views: 264

pic 10.jpg641.3 KB · Views: 264 -

pic 11.jpg382.3 KB · Views: 256

pic 11.jpg382.3 KB · Views: 256 -

pic 12.jpg534.7 KB · Views: 259

pic 12.jpg534.7 KB · Views: 259 -

pic 13.jpg555.6 KB · Views: 275

pic 13.jpg555.6 KB · Views: 275 -

pic 14.jpg363.4 KB · Views: 216

pic 14.jpg363.4 KB · Views: 216

Looks great Denny and nice pictures!

My (newest with updated board) ASC1 took a lightning hit that damaged the main board and the display, so I have to mod the original unit to work. Have all the parts so hope to go ahead once my workbench is cleared up (too many mini projects showing up!).

My (newest with updated board) ASC1 took a lightning hit that damaged the main board and the display, so I have to mod the original unit to work. Have all the parts so hope to go ahead once my workbench is cleared up (too many mini projects showing up!).

- Status

- Please reply by conversation.

Similar threads

- Replies

- 14

- Views

- 910

- Replies

- 0

- Views

- 741

- Replies

- 6

- Views

- 377

- Replies

- 3

- Views

- 688

Users Who Are Viewing This Thread (Total: 0, Members: 0, Guests: 0)

Latest posts

-

L

-

I

-

-

TThe Difficulty in Justifying the macOS Tahoe Menu Icons

- Latest: TWiT Tech Podcast Network