10 Foot Mesh - What Is It?

- Thread starter Horsepower

- Start date

- Latest activity Latest activity:

- Replies 43

- Views 5K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Please reply by conversation.

Don't know about the dish but that's a VonWeise actuator on that thing and it's likely worth it's weight in gold if it's not horked up from the exposure to the elements! I've got 3 of those up and running now and they are a good piece for sure!

The rest of it......... Well, I guess it's OK if you need a project to work on!

The rest of it......... Well, I guess it's OK if you need a project to work on!

The actuator still has the boot etc. intact. They said it was working, which really means nothing 20 years later. I'll have to hook it up to find out.Don't know about the dish but that's a VonWeise actuator on that thing and it's likely worth it's weight in gold if it's not horked up from the exposure to the elements! I've got 3 of those up and running now and they are a good piece for sure!

The rest of it......... Well, I guess it's OK if you need a project to work on!

The only thing I'm worried about is either finding panels, or being able to make some out of that type mesh.

Looks like a old 10 foot Unimesh. You have your work cut out for you!

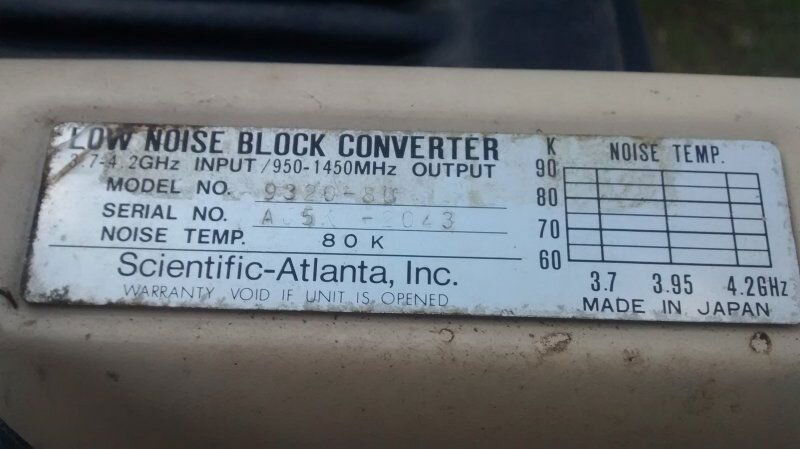

As for the LNB - it's an 80 Kelvin model. It might still work but will not be good with weak signals. Its best place is on the shelf in a museum. The least expensive alternative would be to replace the whole feed assembly with a voltage-controlled LNBF such as the Titanium C1-PLL or one of its variants. Alternatively you could get a lower noise LNB (15 to 20 K) and reuse that feedhorn but then you need to be able to control the servo motor to change between H and V.

about the actuator (I agree with Lone Gunman, that's a great one), try powering it with a low-voltage source (I use an 18V cordless drill battery) to test it. This way if it's seized by rust, at least you'll reduce the risk of breaking the gears. But regardless you might want to take it appart and clean and lube the screw. Take plenty of notes and photos as you are taking it apart, so that you know how to reassemble it.

I have no idea about where to find some mesh but it's hard to tell from the photos how much of it is missing. It might be worth tucking the loose mesh back in place and trying the dish despite it having a few holes before you spend too much time and $ on trying to find replacement mesh. If you decide to look for some mesh and find some, please post the info on this forum. Many here will thank you.

about the actuator (I agree with Lone Gunman, that's a great one), try powering it with a low-voltage source (I use an 18V cordless drill battery) to test it. This way if it's seized by rust, at least you'll reduce the risk of breaking the gears. But regardless you might want to take it appart and clean and lube the screw. Take plenty of notes and photos as you are taking it apart, so that you know how to reassemble it.

I have no idea about where to find some mesh but it's hard to tell from the photos how much of it is missing. It might be worth tucking the loose mesh back in place and trying the dish despite it having a few holes before you spend too much time and $ on trying to find replacement mesh. If you decide to look for some mesh and find some, please post the info on this forum. Many here will thank you.

Thanks guys. The way I see it, about half of them should be replaced from limbs falling off trees that grew up around the thing. Making the mesh panels should be no problem for me. Getting the curvature correct will be the challenge. I just need to find the material.

Sometimes the mesh can be repaired if it's all there but just torn. Here is a thread where I fixed up an 8' mesh dish...Thanks guys. The way I see it, about half of them should be replaced from limbs falling off trees that grew up around the thing. Making the mesh panels should be no problem for me. Getting the curvature correct will be the challenge. I just need to find the material.

8' dish finally repaired

Last edited:

Just be aware that a mesh dish requires a smaller mesh openings for Ku than it does for Cband so make sure the new stuff matches what's on that dish now.

That stuff in your picture is "listed" as 1/8" GALVANIZED, meaning it's STEEL and that may be an issue in both weight and how long it will last. That dish doesn't look all that robust to begin with.

And on another note, the mesh you have "might" be repairable. I've straightened out some pretty funky stuff using a LARGE rubber mallet on it on a concrete floor. Work it from both sides and try to get it as flat as you can and it will "usually" conform itself to the contours of the dish when it's installed. Not sure the steel stuff will do that?? But maybe some others have had some experience with the steel mesh can give you some advice on using it.

That stuff in your picture is "listed" as 1/8" GALVANIZED, meaning it's STEEL and that may be an issue in both weight and how long it will last. That dish doesn't look all that robust to begin with.

And on another note, the mesh you have "might" be repairable. I've straightened out some pretty funky stuff using a LARGE rubber mallet on it on a concrete floor. Work it from both sides and try to get it as flat as you can and it will "usually" conform itself to the contours of the dish when it's installed. Not sure the steel stuff will do that?? But maybe some others have had some experience with the steel mesh can give you some advice on using it.

Thanks for the tips. I haven't even seen the stuff in person yet. It just seems thus far it is the best candidate. I did find some metal supply places that carry all sorts of expanded metal in sheets, or cut to size. Their pricing seemed way high to me.Just be aware that a mesh dish requires a smaller mesh openings for Ku than it does for Cband so make sure the new stuff matches what's on that dish now.

That stuff in your picture is "listed" as 1/8" GALVANIZED, meaning it's STEEL and that may be an issue in both weight and how long it will last. That dish doesn't look all that robust to begin with.

And on another note, the mesh you have "might" be repairable. I've straightened out some pretty funky stuff using a LARGE rubber mallet on it on a concrete floor. Work it from both sides and try to get it as flat as you can and it will "usually" conform itself to the contours of the dish when it's installed. Not sure the steel stuff will do that?? But maybe some others have had some experience with the steel mesh can give you some advice on using it.

The dish is solid. The panels have taken some abuse.

I worked on a 6 footer that had some panel damage a year or so ago. I echo the sentiment, it can be done in most cases. If the "pie" shape pieces are still good or if you can duplicate it, carefully working a flat piece into the grooves actually goes fairly nicely. TI did what was mentioned earlier in this thread of the flattening of the existing piece for re-placement back in to it's own original place. The only reason I did not keep mine was that a 6-footer of the type I had was rather flimsy, but I did learn a little about mesh repair and some other things by working on it. Hope this one works out for you.

I'll also contribute a thread, for what it's worth on my small 6 foot project which was a restoration success, but not so much for "signal."

I'll also contribute a thread, for what it's worth on my small 6 foot project which was a restoration success, but not so much for "signal."

Thanks Radio. The dish I have (hard to see in the photos) has the mesh riveted to the outside. There is no groove. I will probably use self tapping screws with washers to fix/replace what is there.I worked on a 6 footer that had some panel damage a year or so ago. I echo the sentiment, it can be done in most cases. If the "pie" shape pieces are still good or if you can duplicate it, carefully working a flat piece into the grooves actually goes fairly nicely. TI did what was mentioned earlier in this thread of the flattening of the existing piece for re-placement back in to it's own original place. The only reason I did not keep mine was that a 6-footer of the type I had was rather flimsy, but I did learn a little about mesh repair and some other things by working on it. Hope this one works out for you.

I'll also contribute a thread, for what it's worth on my small 6 foot project which was a restoration success, but not so much for "signal."

FYI,On that SAMI dish I had the panels were screwed on with small semi-flat head phillips head sheet metal screws with no washers. No grooves for the mesh to fit in like on my Winegard dish.

LOL. Photos can be deceiving. In this case, the dish is in much better shape than it looks in the photos, and the mesh is in much worse shape than it appears.

If it was easy, then anyone could do it!! I'm sure you'll get it figured out!!

It's been a couple of weeks now. How are you coming along with this dish project?

Thanks guys. The way I see it, about half of them should be replaced from limbs falling off trees that grew up around the thing. Making the mesh panels should be no problem for me. Getting the curvature correct will be the challenge. I just need to find the material.

If it is a Unimesh, the screen fits into a slot on both sides of the rib. The problem is getting to the slot at the outer edge of the dish. I have two Unimesh dishes, and they have a lip covering the end of the mesh on the outer edge of the dish. It prevents you from getting to the slots so you can slide new screen into the channel.

As far as I can tell, there's no way to remove the outer edge of the frame to expose the end of the slots. I have a small battery operated reciprocating saw that uses a hack saw blade. I have been kicking around the idea of cutting the lip off the end of the frame to expose the slots. I's not sure why they did it that way because there are two sets of screws that hold the mesh in place.

My Winegard Quadstar is the same way. I was able to gently pry open that outer edge lip, and get the mesh out to repair some damage and put it back in. Not fun nor easy to do but it worked.If it is a Unimesh, the screen fits into a slot on both sides of the rib. The problem is getting to the slot at the outer edge of the dish. I have two Unimesh dishes, and they have a lip covering the end of the mesh on the outer edge of the dish. It prevents you from getting to the slots so you can slide new screen into the channel.

As far as I can tell, there's no way to remove the outer edge of the frame to expose the end of the slots. I have a small battery operated reciprocating saw that uses a hack saw blade. I have been kicking around the idea of cutting the lip off the end of the frame to expose the slots. I's not sure why they did it that way because there are two sets of screws that hold the mesh in place.

Waiting for the friend who has to go with me to the lady's property.It's been a couple of weeks now. How are you coming along with this dish project?

In the meanwhile, I have been given a fiberglass dish that I can't get to because the yard is so wet.

Hope to have them both home soon. I have dug the hole for the mesh dish.

- Status

- Please reply by conversation.

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 27

- Views

- 3K

- Replies

- 5

- Views

- 1K

- Replies

- 2

- Views

- 2K