schedule 40 PVC pipe for the Feed-horn support

Congraduations on your new dish. It does look like it is an interesting one too. Certaintly one that had some kind of thought going into it for design, like using schedule 40 PVC pipe for the Feed-horn support. Can't wait to see lots of pictures of it in the future. From looking at the photo.... is that a bungee cord attached to the dish to the support bars?

Thanks,

TOM

P.S. On that other dish that you found and the one that AL thought was used for keep out Terrestrial Interference. Maybe it could be a way to contact some Extra Terrestrial for beaming somebody away??? You know what I mean without saying any names!

Hey Fred,Well I have the dish home.

The diameter from the tip of the outer edge to the other outer edge is 6 foot 4 inches.

I put the string test on it, and it is perfect as far as not being warped.

What the guy said was true because the paint has peeled off a small area exposing the solid aluminum sheet on the reflector side with fiberglass on the back side for stability.

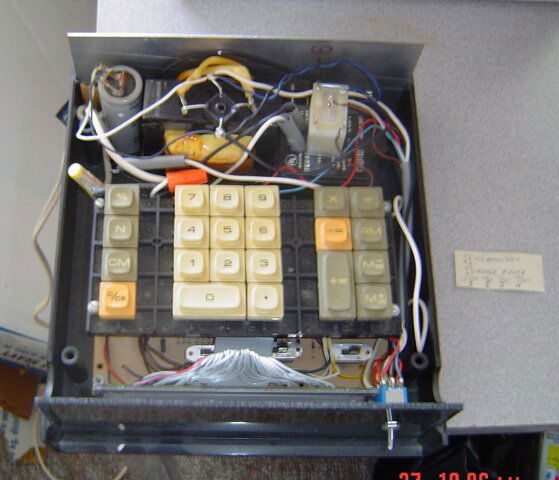

He only bought the reflector part from some manufacturer, and hand made the mount, the elevation and declination adjustments, the motor drive, and the electronic positioner wired through a calculator with display on the front. Pretty smart guy, but I will probably just hook up his motor drive to a GBox.

The online calculations show it to have a Focal distance of 25.7 inches, and an F/D ration of 0.34, so it is almost average as far as depth. I will have pictures a little later. My wife just got back with the camera, and I'll have to off-load all of their pictures before I can use it.

The Feed-horn support is made out of schedule 40 PVC pipe, and after studying it a while, I think it might not be a bad way to make one. I will need to figure out a way to adjust the height unless he has it right on the money.

I think it is going to be fun to play with, and might be a secondary Ku testing unit on the parking lot out front.

His polar mount is very simplistic in the way he designed it, and the mover design is a hoot.

But hey, if it works, I will not complain.

Congraduations on your new dish. It does look like it is an interesting one too. Certaintly one that had some kind of thought going into it for design, like using schedule 40 PVC pipe for the Feed-horn support. Can't wait to see lots of pictures of it in the future. From looking at the photo.... is that a bungee cord attached to the dish to the support bars?

Thanks,

TOM

P.S. On that other dish that you found and the one that AL thought was used for keep out Terrestrial Interference. Maybe it could be a way to contact some Extra Terrestrial for beaming somebody away??? You know what I mean without saying any names!

: Just want to be top notch before I start working.

: Just want to be top notch before I start working.