What causes an actuator to make a loud grinding noise on the downstroke? Mine grinds so LOUD you can hear it inside quite clearly. Drive it up the arc, no noise. Sounds like its coming apart!

Horrible Grinding Noise From my Actuator....

- Thread starter stogie5150

- Start date

- Latest activity Latest activity:

- Replies 17

- Views 5K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Please reply by conversation.

Have you ever oiled it? Mine was making a lot of noise so I ran it as far west as it would go, drilled a quarter inch hole on the top of the arm so I could see the screw and poured 90 weight gear oil into it. That seemed quite it down a lot so now every fall I dump some oil in it to get it through the winter.

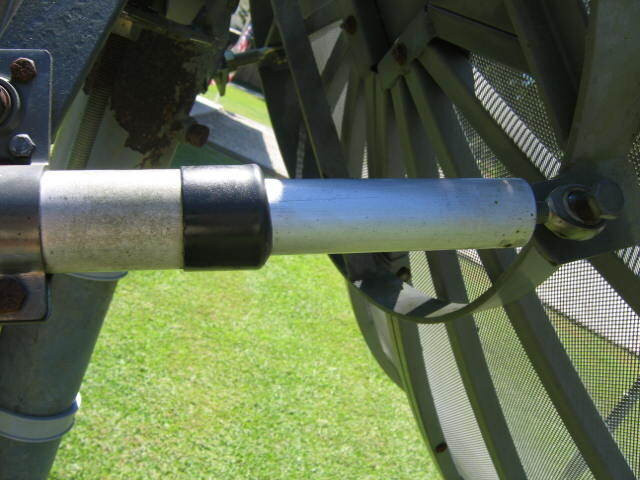

Gabshere and I are swapping PM's on it right now. On the eye end of the arm there are two holes already drilled, top and bottom of the arm. I got my squirt can and tried to squirt some oil in there and it won't go. I took a scribe and poked the holes, they seem to be clear...might need to drill them bigger. The holes are in the second and third pic.

Attachments

I forgot to tell you that after I put the oil in the hole I would run it all of the way to the east then run it back to the west and add some oil then run it back to the east. I did that maybe five or six times. It really worked the oil in, which was good, because I had never lubed it before.

Jim,

I took your advice, drilled a 3/16 hole in the top of the arm, took my squirt can with 10w30 synthetic in it, just started pumping it in there, moving it east to west as I did it. Seemed to have worked much better, just a few spots with the grinding noise.... I put quite a bit in there, did you mean to say that you filled the tube ALL the way up? Like completely full? I have some Mobil 1 Synthetic gear oil, tomorrow morning I will fill it up to the top if that's what you meant.

I took your advice, drilled a 3/16 hole in the top of the arm, took my squirt can with 10w30 synthetic in it, just started pumping it in there, moving it east to west as I did it. Seemed to have worked much better, just a few spots with the grinding noise.... I put quite a bit in there, did you mean to say that you filled the tube ALL the way up? Like completely full? I have some Mobil 1 Synthetic gear oil, tomorrow morning I will fill it up to the top if that's what you meant.

Stogie,

I didn't "fill" it up if you mean like filling your gas tank. I just keep squirting a little bit at a time then moved the dish and squirt some more. I did that until it started to quiet down. By moving the dish the screw would rotate and spread the oil up and down it and into the device that made the screw draw back and forth. NO, don't fill it completely, I don't think that would be good. Do it just enough to get the screw well lubricated. I would say I used maybe 2 pints of oil the first time I did it, since I now do it on a regular basis it doesn't take so much. One time I used grease and that didn't work too good. The grease fitting is right next to the drain hole and it clogged it up. When I noticed that I cleaned the hole out and water drained like it was coming out of a faucet. GREASE IS A NO NO!!!

This came about because my original arm broke. The screw was rusted and just snapped. My late father, who was a machinest, among his other trades looked at it and said in a playful father and son moment: "have you ever put any oil on this?" When I said no, he just shook his head and said "dumbass." He gave me the idea that I have just shared with you. He also had me use the 90wt gear oil because he deduced that since the arm had a hole at the bottom for water drainage that light weight oil would do the same. I've had this dish for 24 years and this is my second arm. I would probably still have the original if I would have been smart enough to do this in the begining. The "old man" has been gone since '97, so I would say it was about '90 or '91 when we did this. As a matter of fact since you brought this up I think I will do it tomorrow. Usually I forget until it's about 10 degress with a 20 mph wind then I freeze my butt off doing it.

I didn't "fill" it up if you mean like filling your gas tank. I just keep squirting a little bit at a time then moved the dish and squirt some more. I did that until it started to quiet down. By moving the dish the screw would rotate and spread the oil up and down it and into the device that made the screw draw back and forth. NO, don't fill it completely, I don't think that would be good. Do it just enough to get the screw well lubricated. I would say I used maybe 2 pints of oil the first time I did it, since I now do it on a regular basis it doesn't take so much. One time I used grease and that didn't work too good. The grease fitting is right next to the drain hole and it clogged it up. When I noticed that I cleaned the hole out and water drained like it was coming out of a faucet. GREASE IS A NO NO!!!

This came about because my original arm broke. The screw was rusted and just snapped. My late father, who was a machinest, among his other trades looked at it and said in a playful father and son moment: "have you ever put any oil on this?" When I said no, he just shook his head and said "dumbass." He gave me the idea that I have just shared with you. He also had me use the 90wt gear oil because he deduced that since the arm had a hole at the bottom for water drainage that light weight oil would do the same. I've had this dish for 24 years and this is my second arm. I would probably still have the original if I would have been smart enough to do this in the begining. The "old man" has been gone since '97, so I would say it was about '90 or '91 when we did this. As a matter of fact since you brought this up I think I will do it tomorrow. Usually I forget until it's about 10 degress with a 20 mph wind then I freeze my butt off doing it.

my arm has a grease hole, is that what its for or is that for something else?

If it's a hole it could be for water drainage or to apply oil, chances are it's for water. The grease fitting will be a silver nipple with a hole in it.

I'd use grease gun

If your motor has a grease fitting, by all means, use it. A couple of times a year I shoot a bit of grease into my old cheap superjacks. One of them has been working since 1997 lol. Of course we don't get super-cold winters here, but they have been through plenty of ice and freezing temps.

A lot of the actuators have a drain hole in the bottom of the motor housing-that is why they tell you to mount the actuator MOTOR UP, so the condensation can drain out. Motor oil might make it work a bit longer if its already making noise, but I wouldn't put too much in one, mess up your wiring and electronic parts. (I know, I did it one time!)

If your motor has a grease fitting, by all means, use it. A couple of times a year I shoot a bit of grease into my old cheap superjacks. One of them has been working since 1997 lol. Of course we don't get super-cold winters here, but they have been through plenty of ice and freezing temps.

A lot of the actuators have a drain hole in the bottom of the motor housing-that is why they tell you to mount the actuator MOTOR UP, so the condensation can drain out. Motor oil might make it work a bit longer if its already making noise, but I wouldn't put too much in one, mess up your wiring and electronic parts. (I know, I did it one time!)

three of mine also have grease fittings

i suspect the grease is for the shaft screw and not the shaft (arm)

also it had white grease on the gears on two i opened.

i suspect the grease is for the shaft screw and not the shaft (arm)

also it had white grease on the gears on two i opened.

Yeah I took the motor cover off and it had white grease on the gears...I squirted a little oil on them anyway until I can get some white grease... I do not see any grease fittings on the tube anywhere, the hole I drilled might be the only way.

I probably put about a half pint of oil in there, this morning I'll run it back and forth some more and see how it is, maybe stop along the way up and down the arc and shoot a little in there. I didn't see any run out, but I oiled it and then went back inside, it was getting dark. There may be a puddle of oil out there this morning....

Thanks to all of you for the info! :up

I probably put about a half pint of oil in there, this morning I'll run it back and forth some more and see how it is, maybe stop along the way up and down the arc and shoot a little in there. I didn't see any run out, but I oiled it and then went back inside, it was getting dark. There may be a puddle of oil out there this morning....

Thanks to all of you for the info! :up

I hope nobody has taken this wrong. In no way am I saying to put oil in the motor. That should be greased. I am talking about keeping the screw in the arm well lubricated. As I said, if it gets rusted it will snap, I know from experience. It was the arm that was making noise for me, not the motor.

If you want to talk about motors, my Dad was a whiz with them also. He loved playing with electric motors. My first one went out and he took it apart and did something to it and got it going again. He did that maybe two or three times and I got maybe 3 more years out of it. He said not to buy a new one until he told me to. Damn, I miss him.

If you want to talk about motors, my Dad was a whiz with them also. He loved playing with electric motors. My first one went out and he took it apart and did something to it and got it going again. He did that maybe two or three times and I got maybe 3 more years out of it. He said not to buy a new one until he told me to. Damn, I miss him.

Well guys, I went out this morning and serviced the arm and motor. I squirted maybe a quarter of a pint of oil in the arm and took the cover off the motor and shot some WD40 on the gears and the screw. The only noise I hear is the motor purring like a kitten.

I have to say, at one time it was pretty loud. I could hear in the front room. The wife would complain about me keeping her awake because of the noise, the bedroom window is about 20 feet away from the dish, since I started keeping it oiled I run it any time during the night and I haven't heard one complaint from her. Now if I could just master everything else in this 30 year marriage.

I have to say, at one time it was pretty loud. I could hear in the front room. The wife would complain about me keeping her awake because of the noise, the bedroom window is about 20 feet away from the dish, since I started keeping it oiled I run it any time during the night and I haven't heard one complaint from her. Now if I could just master everything else in this 30 year marriage.

Well....I wish my news was better. But MY problem is in the motor. I brought the positioner box out to the dish this morning, some gear oil, I was ready to rock. Hooked up the box, started moving the arm...the motor started howling like its was seizing up. I've burned up electric motors before...so I know what THAT sounds like...

So I oiled the arm good, but the motor is howling like a tortured cat. Can you change out just the motor? I wouldn't see why not unless the gears aren't universal. Doesn't look like much holding it on there, two bolts all the way through, some wires, should come right out. Am I missing anything?

So I oiled the arm good, but the motor is howling like a tortured cat. Can you change out just the motor? I wouldn't see why not unless the gears aren't universal. Doesn't look like much holding it on there, two bolts all the way through, some wires, should come right out. Am I missing anything?

The brushes might have burned out. They can be replaced. That's what Dad kept doing to mine when he stretched out the life of that baby. I'd pull it off and have it checked out first. $25.00 sounds awful cheap to me.

Heck for what Sadoun wants for a complete new one, I might just go that route, I dunno. 25 bucks though...wonder how I could know if it will mate to my arm assembly?

I have a crackerjack starter/alternator shop here in town, problem will be getting brushes for it, and if they CAN rebuild it I doubt it will be less than 25.00. I guess I'll just have to think about it for awhile....

Whats the deal with acme screw versus ball actuators?

I have a crackerjack starter/alternator shop here in town, problem will be getting brushes for it, and if they CAN rebuild it I doubt it will be less than 25.00. I guess I'll just have to think about it for awhile....

Whats the deal with acme screw versus ball actuators?

i suspect the motor that sadouns sells won't fit

the one sadouns sells fits the superjack / moteck type actuator

i will keep looking , i have other options but will wait a few hours to post...

the one sadouns sells fits the superjack / moteck type actuator

i will keep looking , i have other options but will wait a few hours to post...

- Status

- Please reply by conversation.

Similar threads

- Replies

- 0

- Views

- 564

- Replies

- 0

- Views

- 646

- Replies

- 0

- Views

- 731

- Replies

- 47

- Views

- 3K

Users Who Are Viewing This Thread (Total: 0, Members: 0, Guests: 0)

Who Read This Thread (Total Members: 1)

Latest posts

-

-

-

Internet's Single Point of Failure? Let's Encrypt Risk! #shorts

- Latest: one_db_compression

-

-