I have to mount an 8 foot solid aluminum dish. It weighs around 137 pounds according to the catalog. It feels heavy for sure. I'm thinking of welding one up. But, I figured I'd ask around and see they make something worth looking into. If it costs way too much for a sturdy one, I'll weld one up. Id like a stationary setup that I could add an actuator arm to later.

Looking for an 8 foot solid dish mount options

- Thread starter jugghedd

- Start date

- Latest activity Latest activity:

- Replies 33

- Views 10K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Please reply by conversation.

I would look for a junk BUD for free.

The worse the dish, the better.

Keep the pole, mount, and actuator.

All you need do is weld up a few brackets to mate to your dish...which you still haven't provided back side views of yet.

Probably best to run pictures of any candidate dishes past the troops for comments.

I'm sure the guys 'n gals will guide you to the best one.

The worse the dish, the better.

Keep the pole, mount, and actuator.

All you need do is weld up a few brackets to mate to your dish...which you still haven't provided back side views of yet.

Probably best to run pictures of any candidate dishes past the troops for comments.

I'm sure the guys 'n gals will guide you to the best one.

I've been eye ballin this mesh dish with a section missing up the road. Its pointing at the mountain. Maybe I'll drop a note in the mailbox and take some junk off their hands as well as throw them a few bucks. It does sound better than making or buying a new one. I just wondered of a mesh mount would be too weak. Looks like its an 8-10 footer.

Jugg you should look for a fiberglass dish. They too are very heavy and have good mounts, stronger than the mesh dish mounts.

Here are a few photos of my solid aluminum dish that looks much like yours. It is a Andrew microwave dish that was used for point to point communications in the cable tv service. I found a 8' fiberglass dish and salvaged the mount and the button hook feed mount.

Here are a few photos of my solid aluminum dish that looks much like yours. It is a Andrew microwave dish that was used for point to point communications in the cable tv service. I found a 8' fiberglass dish and salvaged the mount and the button hook feed mount.

The existing ring on the back distributes stress evenly across the dish, so I would err on the side of caution and keep it all.

I don't have any mesh dishes, but would expect it to be half the weight of yours.

The 8' perf in my signature is about that.

Unless someone has conflicting experience, I'd think the mount you found might work.

Again, get pictures; someone here will have a better informed opinion than me.

Worst case, we might discuss a counterweight...

edit: just saw what Pixl posted.

Great input on the heavy-dish mount.

The solid spun aluminum Birdview in my sig is probably 125-150 lbs.

A real handfull for two people! and best with three!

and best with three!

But it's on an H-H mount built like a tank! No counterweight needed.

I don't have any mesh dishes, but would expect it to be half the weight of yours.

The 8' perf in my signature is about that.

Unless someone has conflicting experience, I'd think the mount you found might work.

Again, get pictures; someone here will have a better informed opinion than me.

Worst case, we might discuss a counterweight...

edit: just saw what Pixl posted.

Great input on the heavy-dish mount.

The solid spun aluminum Birdview in my sig is probably 125-150 lbs.

A real handfull for two people!

But it's on an H-H mount built like a tank! No counterweight needed.

Thanks Pixl! Any chance you can share insight in how you mounted the LNB on the buttonhook? Id love to do that if I could figure out a stable way. I was going to use a tripod setup instead. But, I have the buttonhook waveguide still.

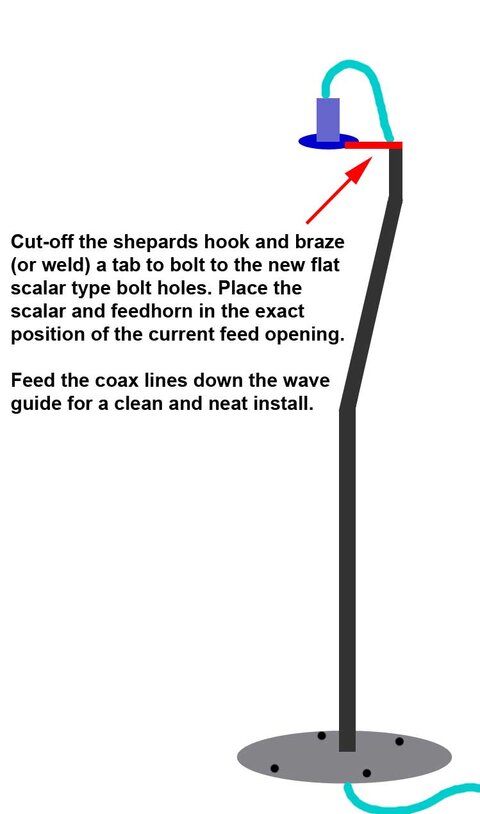

The button hook mount I used came from the salvaged fiberglass dish and already had a flat plate with holes that match the lnbf I used. The original microwave waveguide button hook would be difficult to adapt a lnbf to it. If your original waveguide is undamaged you should measure the focal distance from the dish face to the opening. Use this measurement to help with your new mount. Here is a picture of my original waveguide, it got bent up by the tower crew that took the dish down. Does yours look like this?

Thanks AV. Nice diagram. Im going to look at some parts this afternoon and may have an LNB like that. I hope so because the flat mount looks like a way nicer fit. My big issue with the other style was stabilizing the round body of the LNB in a way that it could be adjusted for skew and distance. With the plate and flat mount, I could make slots to allow for skew adjustment too. Got some ideas brewin! Seeing all the options help a whole lot.

I dont know why the center LNB isnt used more often. With guy wires, it appears to be a really nice and stable setup. I guess sometimes its a matter of whats available to use.

I dont know why the center LNB isnt used more often. With guy wires, it appears to be a really nice and stable setup. I guess sometimes its a matter of whats available to use.

Typically the scalar is used to mount the feedhorn and allows adjustment of the FD and Skew. The scalar has a throat to insert the feedhorn and tapped for tensioning screws. The scalar also has four or five tapped holes for mounting to the support buttonhook or legs.

I went to pick up the LNB yesterday. Im so glad I did. I got to meet a guy that was an installer "back in the day". He gave me an actuator, 3 receivers, motor power unit, LNB, manuals, and lots of knowledge. Its great to meet people who have the same mindset and are so willing to share their experiences and "toys". Now I have lots to do so I can figure out how all these things work. Its so weird to see a manual knob and fine tuning on a receiver Pretty darn cool! I also got a lead on a mount for the dish. Woo hoo!

Just an update. The same guy hooked me up with a 7.5 foot mesh dish with mount, actuator arm, good Ku/C LNB with a polar rotor. So, now the job gets easier. Sink a pole in the ground and Im all set. Cant wait.

Just an update. The same guy hooked me up with a 7.5 foot mesh dish with mount, actuator arm, good Ku/C LNB with a polar rotor. So, now the job gets easier. Sink a pole in the ground and Im all set. Cant wait.

Good to hear! We can help you with tech advice.

The dish/motor/mount sounds like just what the doctor ordered. :up

Take some pictures of it and the rest of your haul.

Sometimes we get distracted by freebie junk.

The members here will recognize most of your toys and offer advice on what to use and what to retire.

Take some pictures of it and the rest of your haul.

Sometimes we get distracted by freebie junk.

The members here will recognize most of your toys and offer advice on what to use and what to retire.

I planned on trying the setup the way it is first. Seemed like an easy option. And its setup for the arc already if it stayed through the trip. Has a Chaparral KU and C LNB with a polar rotor. Pics attached. That looked like a good quality part. I removed it to clean spider webs and stuff. I can see mark where it was mounted easily.

I planned on either using the STS MBS-AA Antenna Actuator to move the motor. If not, I have a couple old receivers too. The polar mount, I planned on a 3-3 1/4 OD pipe 8 foot long, 3 foot in the ground, at least 6-8 bags of cement.

If all of that works out well, I'll consider beefing up the mount and using the 8 foot solid dish. But, I get the feeling the 7 1/2 mesh is pretty close in performance. Any thoughts on that or whether to use the BSC621 2D LNBF instead?

I planned on either using the STS MBS-AA Antenna Actuator to move the motor. If not, I have a couple old receivers too. The polar mount, I planned on a 3-3 1/4 OD pipe 8 foot long, 3 foot in the ground, at least 6-8 bags of cement.

If all of that works out well, I'll consider beefing up the mount and using the 8 foot solid dish. But, I get the feeling the 7 1/2 mesh is pretty close in performance. Any thoughts on that or whether to use the BSC621 2D LNBF instead?

You'll have to use an old receiver to operate the polarotor servo for polarity*. Try it, and then the BSC, and compare performance?? *unless you have the Pansat model 9500HDX or another box with servo outputs.

Think the difference in dish performance, between the two, would be unrecognizable on C band. Ku may be a different story. (The solid was designed for Ku)

The ONLY thing, In my view, would be to make sure there's ventilation in that LNB cover. The more the better. Black plastic heats up in the sun. Gets like an oven in there without adequate ventilation. Heat destroys electronics. Even without destroying stuff, may cause excessive LO drift.

Think the difference in dish performance, between the two, would be unrecognizable on C band. Ku may be a different story. (The solid was designed for Ku)

The ONLY thing, In my view, would be to make sure there's ventilation in that LNB cover. The more the better. Black plastic heats up in the sun. Gets like an oven in there without adequate ventilation. Heat destroys electronics. Even without destroying stuff, may cause excessive LO drift.

Thanks Fat! I'll keep that in mind. I always wondered if they were necessary seeing as all the places where electronics exist are sealed up pretty well. Would you say its better to take it right off or just pop some vent holes?

AS far as the dish mover/receiver I have a small pile of receivers here now. Im sure one of them supports a polar rotor. Well, pretty sure.

AS far as the dish mover/receiver I have a small pile of receivers here now. Im sure one of them supports a polar rotor. Well, pretty sure.

- Status

- Please reply by conversation.

Similar threads

- Replies

- 12

- Views

- 751

- Replies

- 6

- Views

- 909

- Replies

- 27

- Views

- 5K

- Replies

- 9

- Views

- 1K