Would you please help me on a project by providing an exact measurement of the inside diameter of your C-band or combined C/KU feedhorn?

1. What Brand and Model?

2. What is the inside diameter measurement at the entrance?

3. What is the depth of the feedhorn before the dielectric guides or other mechanics (probe, waveguide, etc.)?

4. Is the inside diameter of the feedhorn tapered or consistent size diameter?

5. If tapered, what is the diameter measured at 2 inches back from the feedhorn entrance.

6. A photo of the feedhorn entrance would be great, but not necessary.

I am manufacturing a new laser alignment tool for installing and centering a feedhorn on a satellite dish. Want to make sure that it will be an exact fit on as many types and models of C and combined C/KU band feedhorns as possible. While I have about a dozen feedhorns and LNBFs, I know that there are many more that I do not have access to. This is where I need your help.

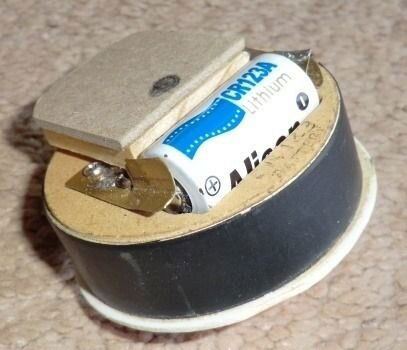

Installing a feedhorn or LNBF so it is aimed to the exact center of the dish is critical to the optimization of a satellite system. Some of us are fortunate to own alignment tools from the early years of BUD installation, while others have used torpedo laser levels to estimate this alignment. My goal for this project is to produce an inexpensive and robust alignment tool that we can carry around in our tool kit for those occasional feedhorn installs. Visualize a hockey puck shape with a lip and a precisely centered laser pointer.

Thanks for your assistance!

1. What Brand and Model?

2. What is the inside diameter measurement at the entrance?

3. What is the depth of the feedhorn before the dielectric guides or other mechanics (probe, waveguide, etc.)?

4. Is the inside diameter of the feedhorn tapered or consistent size diameter?

5. If tapered, what is the diameter measured at 2 inches back from the feedhorn entrance.

6. A photo of the feedhorn entrance would be great, but not necessary.

I am manufacturing a new laser alignment tool for installing and centering a feedhorn on a satellite dish. Want to make sure that it will be an exact fit on as many types and models of C and combined C/KU band feedhorns as possible. While I have about a dozen feedhorns and LNBFs, I know that there are many more that I do not have access to. This is where I need your help.

Installing a feedhorn or LNBF so it is aimed to the exact center of the dish is critical to the optimization of a satellite system. Some of us are fortunate to own alignment tools from the early years of BUD installation, while others have used torpedo laser levels to estimate this alignment. My goal for this project is to produce an inexpensive and robust alignment tool that we can carry around in our tool kit for those occasional feedhorn installs. Visualize a hockey puck shape with a lip and a precisely centered laser pointer.

Thanks for your assistance!