Hello all,

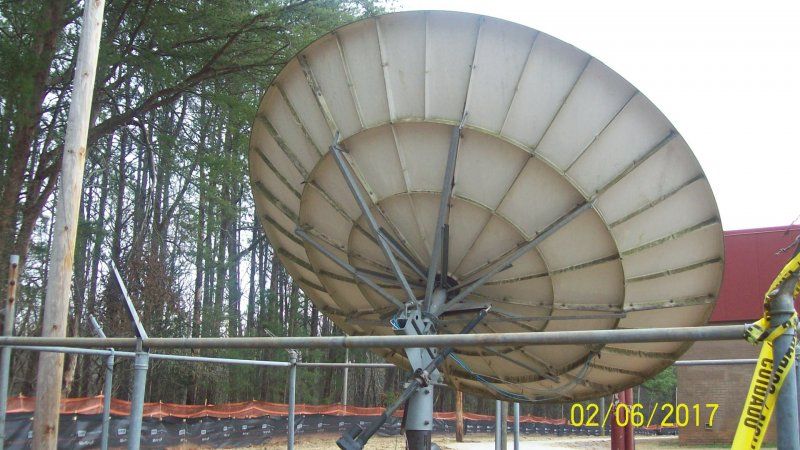

I've found a 12' fiberglass Dish that I'm going to get (free of charge) and relocate it to my home. I've been looking into getting a BUD for a several months and found this one. It looks to be in decent shape and it's motorized. It has 3 cables that go to the head unit. 2 look to be coaxial and 1 control wiring. I should be demoing it next weekend to relocate. Looking forward to the wealth of information here to help me get it installed and into operation. Thanks in advance for any suggestions and or comments.

I've found a 12' fiberglass Dish that I'm going to get (free of charge) and relocate it to my home. I've been looking into getting a BUD for a several months and found this one. It looks to be in decent shape and it's motorized. It has 3 cables that go to the head unit. 2 look to be coaxial and 1 control wiring. I should be demoing it next weekend to relocate. Looking forward to the wealth of information here to help me get it installed and into operation. Thanks in advance for any suggestions and or comments.

to SatelliteGuys

to SatelliteGuys