Happy New Year!!!!

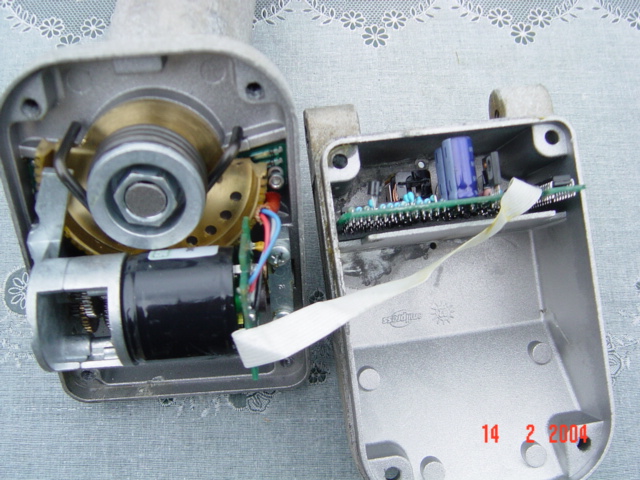

I recently got a used Stab HH-120 motor that is at least 10 years old (according to the previous owner) and I would like to remove the old grease from the gears and replaced with a fresh one. Since Stab is out of business and cannot be contacted anymore, what type of grease is recommended for this motor? Any tip for opening the motor and doing this operation?

I recently got a used Stab HH-120 motor that is at least 10 years old (according to the previous owner) and I would like to remove the old grease from the gears and replaced with a fresh one. Since Stab is out of business and cannot be contacted anymore, what type of grease is recommended for this motor? Any tip for opening the motor and doing this operation?