USALS motors: Most have "enjoyed" these devices at one time or another.

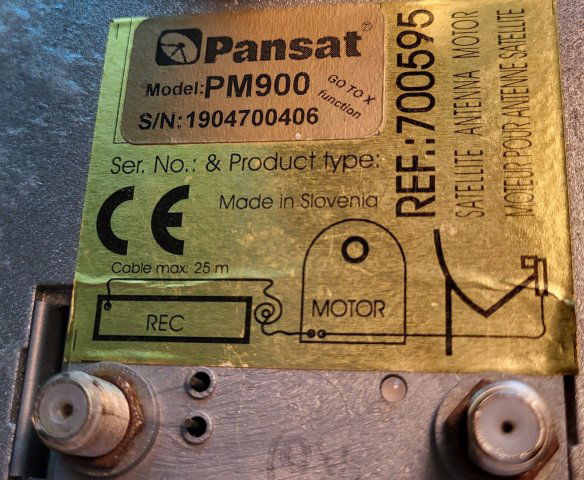

My current headache is caused by a Pansat PM900 motor. I got this motor free used. I have no idea of its history. It looks in reasonably good physical condition with no rust. It moves according to USALS commands sent to it. It just doesn't do so reliably. In fact, it mostly moves to one extreme or the other extreme. Once it starts heading to an extreme end, there's nothing one can do to stop or divert it. Once in a while, it goes to the satellite you tell it to go to.

I am using only USALS commands to keep things simple. I find using diseqc commands to move the motor to a stored satellite location is another level of difficulty.

Measured voltage at the motor with no load is 18.8 volts on a horizontal command. Very reasonable for the long 100+ foot RG6 I'm using. I am using a similar cable on an SG2100 motor without a problem.

I thought maybe my latitude/longitude was entered wrong or the data had been corrupted. So I've reentered the data without a change in operation. I even tried entering "South" instead of "North" for the latitude in case there was a programming error in the software just in case. That didn't help.

I thought maybe the 1.2m dish was too much of a burden. So I swapped for a 41" metal dish. I even replaced the Invacom LNB with a lighter LNB. No change. I can't find much info online. If they were popular, it was likely before the Internet was invented.

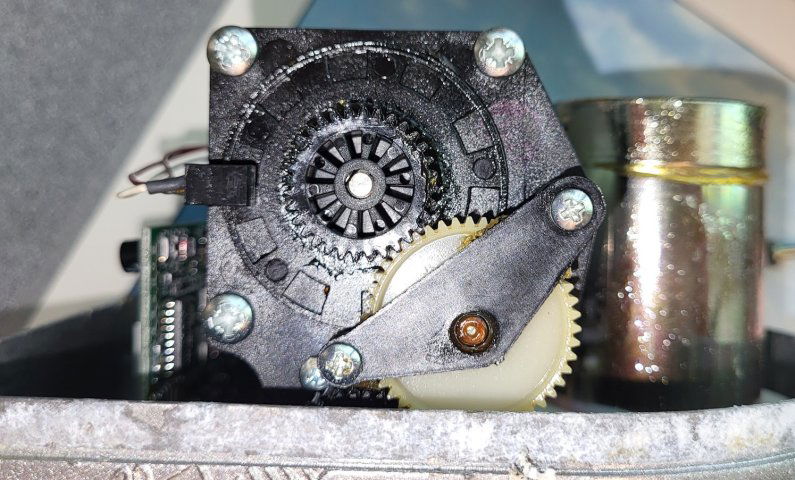

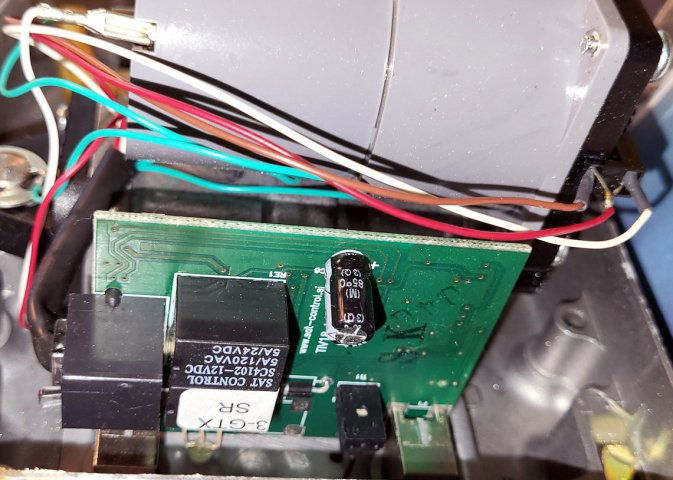

Pressing the physical switches on the motor does cause the motor to move west or east depending which switch you press. So physically it seems fine. The motor just seems to get mixed up about what to do when you send it commands. I don't see a way to reset the motor as you can with the SG2100. I have the original printed manual for the PM900, which is actually quite good in the old style of instruction manuals, but it isn't helping.

I've used both a GT Media V7S5X and an Edision Mio+ receiver. No difference in operation of the motor.

Any ideas?

My current headache is caused by a Pansat PM900 motor. I got this motor free used. I have no idea of its history. It looks in reasonably good physical condition with no rust. It moves according to USALS commands sent to it. It just doesn't do so reliably. In fact, it mostly moves to one extreme or the other extreme. Once it starts heading to an extreme end, there's nothing one can do to stop or divert it. Once in a while, it goes to the satellite you tell it to go to.

I am using only USALS commands to keep things simple. I find using diseqc commands to move the motor to a stored satellite location is another level of difficulty.

Measured voltage at the motor with no load is 18.8 volts on a horizontal command. Very reasonable for the long 100+ foot RG6 I'm using. I am using a similar cable on an SG2100 motor without a problem.

I thought maybe my latitude/longitude was entered wrong or the data had been corrupted. So I've reentered the data without a change in operation. I even tried entering "South" instead of "North" for the latitude in case there was a programming error in the software just in case. That didn't help.

I thought maybe the 1.2m dish was too much of a burden. So I swapped for a 41" metal dish. I even replaced the Invacom LNB with a lighter LNB. No change. I can't find much info online. If they were popular, it was likely before the Internet was invented.

Pressing the physical switches on the motor does cause the motor to move west or east depending which switch you press. So physically it seems fine. The motor just seems to get mixed up about what to do when you send it commands. I don't see a way to reset the motor as you can with the SG2100. I have the original printed manual for the PM900, which is actually quite good in the old style of instruction manuals, but it isn't helping.

I've used both a GT Media V7S5X and an Edision Mio+ receiver. No difference in operation of the motor.

Any ideas?