Normal day here! LOLYou mean this white stuff?

And I'm farther South than Stogie......

stogie5150's Birdview install

- Thread starter stogie5150

- Start date

- Latest activity Latest activity:

- Replies 135

- Views 17K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Please reply by conversation.

What about that white stuff on the ground down there.

Ready to move further South yet?

I'm studying Google Maps as we speak. This is BS! LOL

Only saving grace is that it was melting as fast as it was falling, so that was good....

stogie5150, mabye,......well..............you ,know.................I ..was kind -of-thinkin-............we could,.............you know, kind of exchange info so when I get ready to set my bird view up in spring you can give me a hand?

I caint wait, and with the trouble that RTN networks are going through it is looking like I am going to need that c-band.

On another note SNOW !! Ps, I'm in new iberia louisiana

I am a long ways from New Iberia,Skewed. If you have questions, post away, make a thread for your install, even, and ask away. No question is too dumb. Feel free to shoot me an PM if you need to, also.

Attachments

Last edited:

BREAKING NEWS!!!!!!!!!!!!!!!!

TRAGEDY IN STOGIE5150'S BACKYARD!

The Birdview's motor is bad. Try to move it with a positioner box, it blows the fuse in the box.

So, after a couple calls to the Birdview Reclamation Center in Missouri, the execellent staff there has come to the conclusion that my motor needs rebuilding, and they have no idea HOW to go about that.

I am going to bring it to my local starter/alternator shop and see if they will look at it.

Ideas and ruminations are welcome!

TRAGEDY IN STOGIE5150'S BACKYARD!

The Birdview's motor is bad. Try to move it with a positioner box, it blows the fuse in the box.

So, after a couple calls to the Birdview Reclamation Center in Missouri, the execellent staff there has come to the conclusion that my motor needs rebuilding, and they have no idea HOW to go about that.

I am going to bring it to my local starter/alternator shop and see if they will look at it.

Ideas and ruminations are welcome!

Attachments

TRAGEDY IN STOGIE5150'S BACKYARD!

The Birdview's motor is bad. Try to move it with a positioner box, it blows the fuse in the box.

So, after a couple calls to the Birdview Reclamation Center in Missouri, the execellent staff there as come to the conclusion that my motor needs rebuilding, and they have no idea HOW to go about that.

I am going to bring it to my local starter/alternator shop and see if they will look at it.

Ideas and ruminations are welcome!

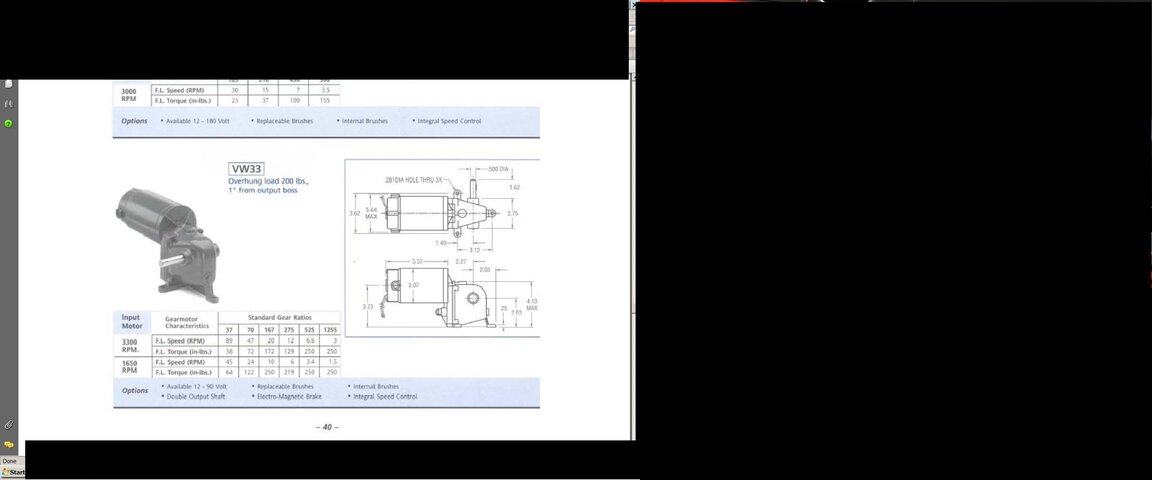

After several conversations with Stogie via phone, PM, and email, Stogie has found the picture below on the Von Weise Website, now a division of White and Green Motors.

It appears to be the same as one of mine here at the shop.

My model number is V03554AE33 which I believe they have shortened to VW33.

EDIT: Mine is 37:1 gear ratio and has 1650 RPM. Also Von Weise's phone number is: 877-891-2161

Here's Stogies pic:

Stogie,

If you have no luck let me know, might be able to help you with your motor problem, i have 2 of them that i know still work might be able to sell you one if you are interested and cannot find a fix locally ..

If you have no luck let me know, might be able to help you with your motor problem, i have 2 of them that i know still work might be able to sell you one if you are interested and cannot find a fix locally ..

The one I have in my closet, that I got from Skyvision about 3-4 years ago has a model number VO3554AH33 and a gear ratio 70:1. It also came with the conversion kit, that aren't made anymore.After several conversations with Stogie via phone, PM, and email, Stogie has found the picture below on the Von Weise Website, now a division of White and Green Motors.

It appears to be the same as one of mine here at the shop.

My model number is V03554AE33 which I believe they have shortened to VW33.

EDIT: Mine is 37:1 gear ratio and has 1650 RPM. Also Von Weise's phone number is: 877-891-2161

Here's Stogies pic:

View attachment 31967

But, I ain't part'in with it.

dead one

If anyone with a dead motor wants to send it to me, I'll reimburse for shipping.

I've already talked to my machinist buddy about brushes, bearings, and (the dreaded) windings, along with weak magnets.

We're mostly on an exploratory mission, to learn what goes wrong with 'em.

If anyone with a dead motor wants to send it to me, I'll reimburse for shipping.

I've already talked to my machinist buddy about brushes, bearings, and (the dreaded) windings, along with weak magnets.

We're mostly on an exploratory mission, to learn what goes wrong with 'em.

Bad windings/armature might be tough, but I'd think a good old-school starter/alternator/motor shop could fix most anything else on these motors.

Anole and I were talking on the phone about the possibility that the GEARBOX might be locked up with 25 year-old grease. I haven't really thought about it. He thinks that it should be cake to take apart and check. I, however, am not that sure what it I start taking screws apart that it won't fly apart like a dollar watch.

Thoughts? Anyone ever take one like that apart, or something similar?

I am kinda under the thought that the damn thing doesn't work anyway, so what the hey?

Thoughts? Anyone ever take one like that apart, or something similar?

I am kinda under the thought that the damn thing doesn't work anyway, so what the hey?

I'd take the back of the motor off and give it a spin.

What will that prove?

If the motor is seized it won't move. If the gearbox is gummed up it still won't move....the motor will run with a battery charger, but NOT a positioner box, it trips the fuse/breaker in the mover box. Which tells me for some reason its drawing too much current. However, it makes NO sound while moving. No scraping, no groaning, no nothing.

Just to feel the movement, if it feels gummed.What will that prove?

Also to look inside for corrosion.

You could also take the Right Angle off for a look, and test without it.

What will that prove?

If the motor is seized it won't move. If the gearbox is gummed up it still won't move....the motor will run with a battery charger, but NOT a positioner box, it trips the fuse/breaker in the mover box. Which tells me for some reason its drawing too much current. However, it makes NO sound while moving. No scraping, no groaning, no nothing.

Stogie;

If it runs with a battery charger, it'll run easier with a good cleaning and fresh lubricant. It looks like a simple gear reduction unit. If you feel a bit intimidated, just take pix of each dissasembly step. Don't force anything apart, take your time. LAk is probably right about the old grease having gotten stiff and waxy. The worst that could happen to you is that it won't run when you're done, same place you are now. You would be amazed what a little kerosene cleanup and some new grease will do for the unit. Gumout for carbs is great for blasting old gummy stuff out of tight spots. Try to not flush any gunk into the motor, If you can get the motor apart, oil the bushings with lightweight oil on the felt pads and replace the brushes if worn too much. If you can't find the exact brushes, go a bit bigger and sand them down to fit inside the brush holders. You've already done all the really hard work.

Stogie;

If it runs with a battery charger, it'll run easier with a good cleaning and fresh lubricant. It looks like a simple gear reduction unit. If you feel a bit intimidated, just take pix of each dissasembly step. Don't force anything apart, take your time. LAk is probably right about the old grease having gotten stiff and waxy. The worst that could happen to you is that it won't run when you're done, same place you are now. You would be amazed what a little kerosene cleanup and some new grease will do for the unit. Gumout for carbs is great for blasting old gummy stuff out of tight spots. Try to not flush any gunk into the motor, If you can get the motor apart, oil the bushings with lightweight oil on the felt pads and replace the brushes if worn too much. If you can't find the exact brushes, go a bit bigger and sand them down to fit inside the brush holders. You've already done all the really hard work.

All that sounds great, but one problem. I know NOTHING about electric motors. I took one apart one time and I didn't ever get it back together. I know an electric motor HAS brushes, but I don't know where they go, what they do, or how to tell if they are bad or not. I am ignorant of the whole thing. Which is why I am loathe to look into the motor.

The gearbox, on the other hand, I might not be so scared to look at.

At any rate, it won't be until Monday at the earliest....I need some time to think it through anyway.

Stogie, you can seperate the motor from the gear box real easy, by just removing the 2 screws on the back plate (their about 5" long) where the red & black wires come out, the just grab the motor an wiggle it back an the spline of the motor arm will come out from gear box. I have canged motors an gear boxs around before.

2 things to watch, the back plate where the screws are if it goes back form the feilds (motor housing) more than 3/8 of inch brushes will come out.

an their is trust washers at the end of the motor where it goes into gear box just make note of their order.

give it a shot it is not bad to pull apart, an you may find that you have bad bearings on the arm, I have seen that before.

2 things to watch, the back plate where the screws are if it goes back form the feilds (motor housing) more than 3/8 of inch brushes will come out.

an their is trust washers at the end of the motor where it goes into gear box just make note of their order.

give it a shot it is not bad to pull apart, an you may find that you have bad bearings on the arm, I have seen that before.

I took an old STS actuator apart that was locked up. Turned out one of the magnets had come free from the side and wedged partially into the coil and one of the 2 bolts that hold it together, then causing the thing to lock in place. I bought some glue and placed it where it appeared to belong and let it set for a couple of days, then put it all back together and it works. It seems slow, but it works and as far as I know it running like it's supposed to.

Pull the brushes out by unscrewing the black plastic caps on the wire lead end of the motor, pay attention to the curvature of the brushes so they go back in with the same orientation. You should be able to read the numbers on the bearings, and get replacements if they're pitted or corroded. Other wise, just clean and regrease. With small motors, grease is like a womans make-up, a little is way better than too much. Several on-line bearing houses to choose from. Im surprised it has real bearings instead of bushings, sign of a good quality motor. Take a photo of the commutator, it looks like a bunch of little copper barrs around one end. If it's not gouged or burnt black, it's probably a good armature. I've rebuilt hundreds of small motors, and have some assorted brushes if you need them, 3/8" or longer is ok, less than that replace them.

Follow Cadsulfide's advise.

Brushes, there are 2, are rectangles of Carbon that pass electricity to the middle part that you are spinning. They are spring loaded, to keep in contact with the part that moves, usually located in / at the end cap.

Graphite Store:*Carbon Brushes Application, Category, Size, Part Number, Motor Manufacturer, Tool Manufacturer, Tool Type, Brush Kits,

Brushes, there are 2, are rectangles of Carbon that pass electricity to the middle part that you are spinning. They are spring loaded, to keep in contact with the part that moves, usually located in / at the end cap.

Graphite Store:*Carbon Brushes Application, Category, Size, Part Number, Motor Manufacturer, Tool Manufacturer, Tool Type, Brush Kits,

- Status

- Please reply by conversation.

Similar threads

- Replies

- 5

- Views

- 2K

- Replies

- 10

- Views

- 2K

- Replies

- 47

- Views

- 3K

- Replies

- 0

- Views

- 491

![IMG_1747[1].JPG](https://cdn.satelliteguys.us/xen/data/attachments/26/26651-8964fc837c89a718cc552c22a65ccb4e.jpg?hash=iWT8g3yJpx)

![IMG_1751[1].JPG](https://cdn.satelliteguys.us/xen/data/attachments/26/26652-098acc64427961f968c02bc603243e5c.jpg?hash=CYrMZEJ5Yf)